Full level steam turbine short movable vane without frequency modulation

A technology of steam turbines and short blades, which is applied to machines/engines, supporting elements of blades, mechanical equipment, etc., and can solve the problems of difficult calculation and accuracy of vibration and difficult to grasp vibration characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

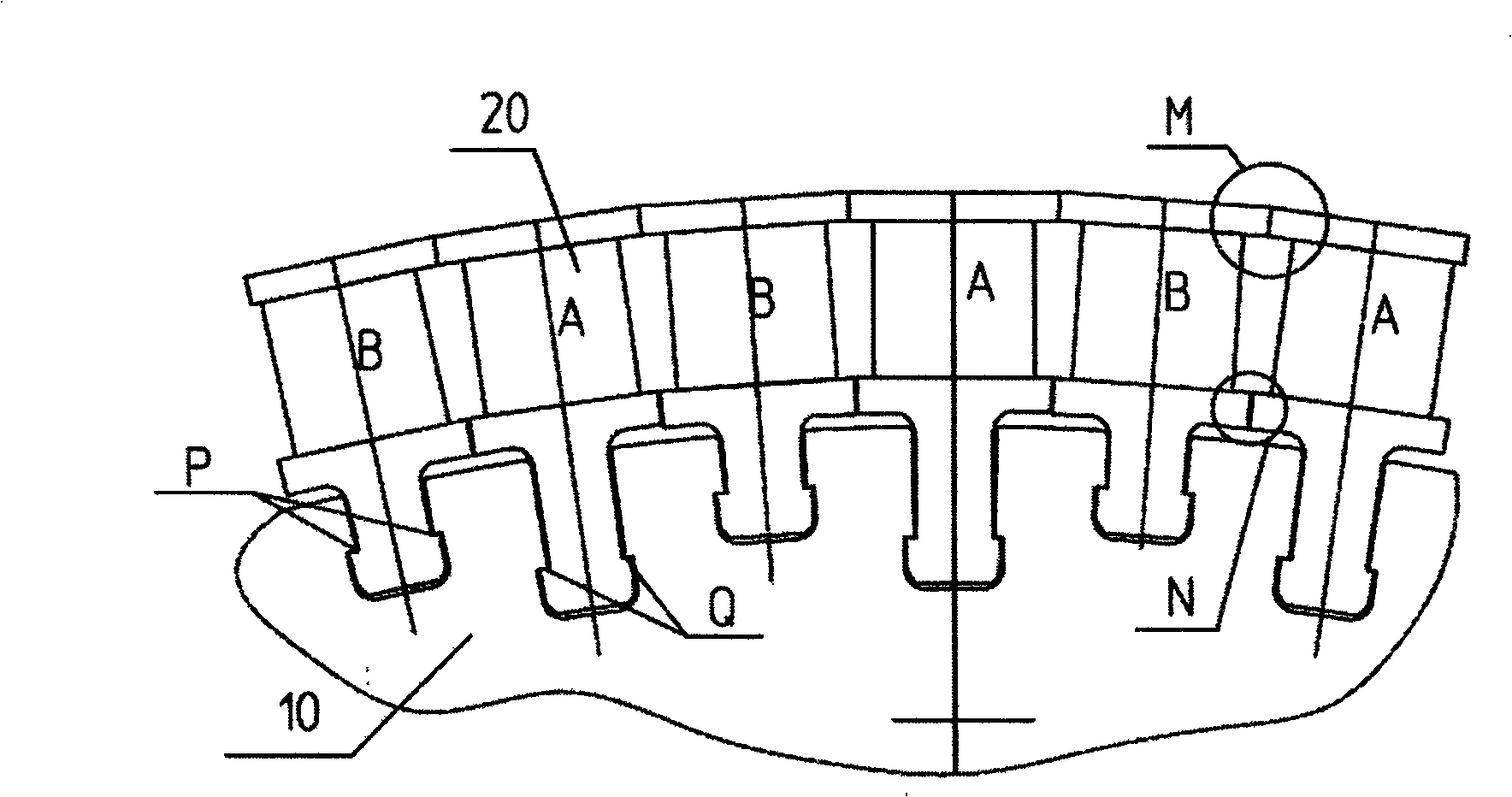

[0021] see Figure 7 : the moving blade 20 of the steam turbine is mounted on the impeller 10.

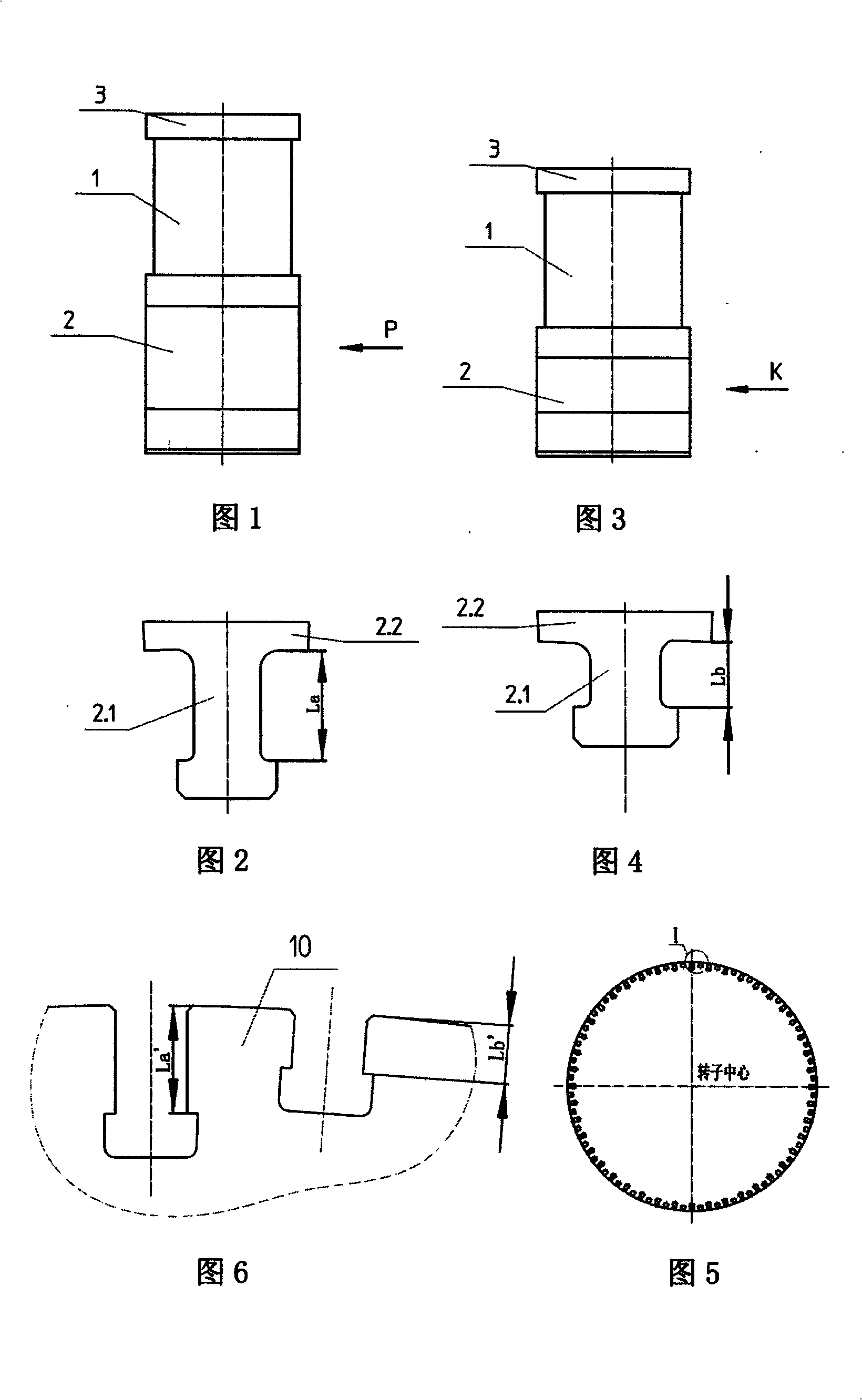

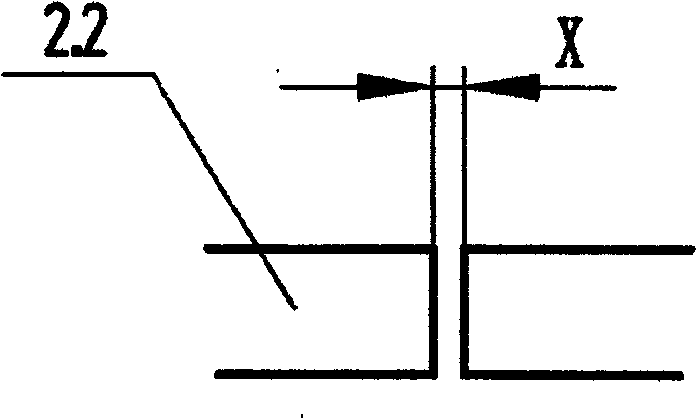

[0022] Referring to Fig. 1 to Fig. 4: the blade 20 has a blade body 1, a blade root 2, and a blade crown 3, and the three are integral structures. Wherein, the blade root 2 has a blade root profile part 2.1 and an intermediate part 2.2, and the two parts are integral structures. The height dimension of the root profile part 2.1 is L.

[0023] The main feature of the present invention is: blade 20 is designed into two kinds, namely A, B, and these two kinds of blades are except that the height dimension L of blade root 2 molded line part 2.1 is different, all the other parts are identical. Fig. 1 and Fig. 2 are the structure of blade A, the height dimension La of the blade root profile part 2.1, Fig. 3 and Fig. 4 are the structure of B blade, the height dimension Lb of the blade root profile part 2.1, La>Lb. Correspondingly, the wheel groove on the impeller 10 is also two kinds, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com