Pervasion auxiliary agent and application in dyeing course and degumming process thereof

An additive, tetradecyl technology, applied in the textile field, can solve the problems of poor homochromaticity and poor color fastness of polyamide and polyurethane two-components, achieve high homochromaticity, overcome dyeing color, and soaping fastness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

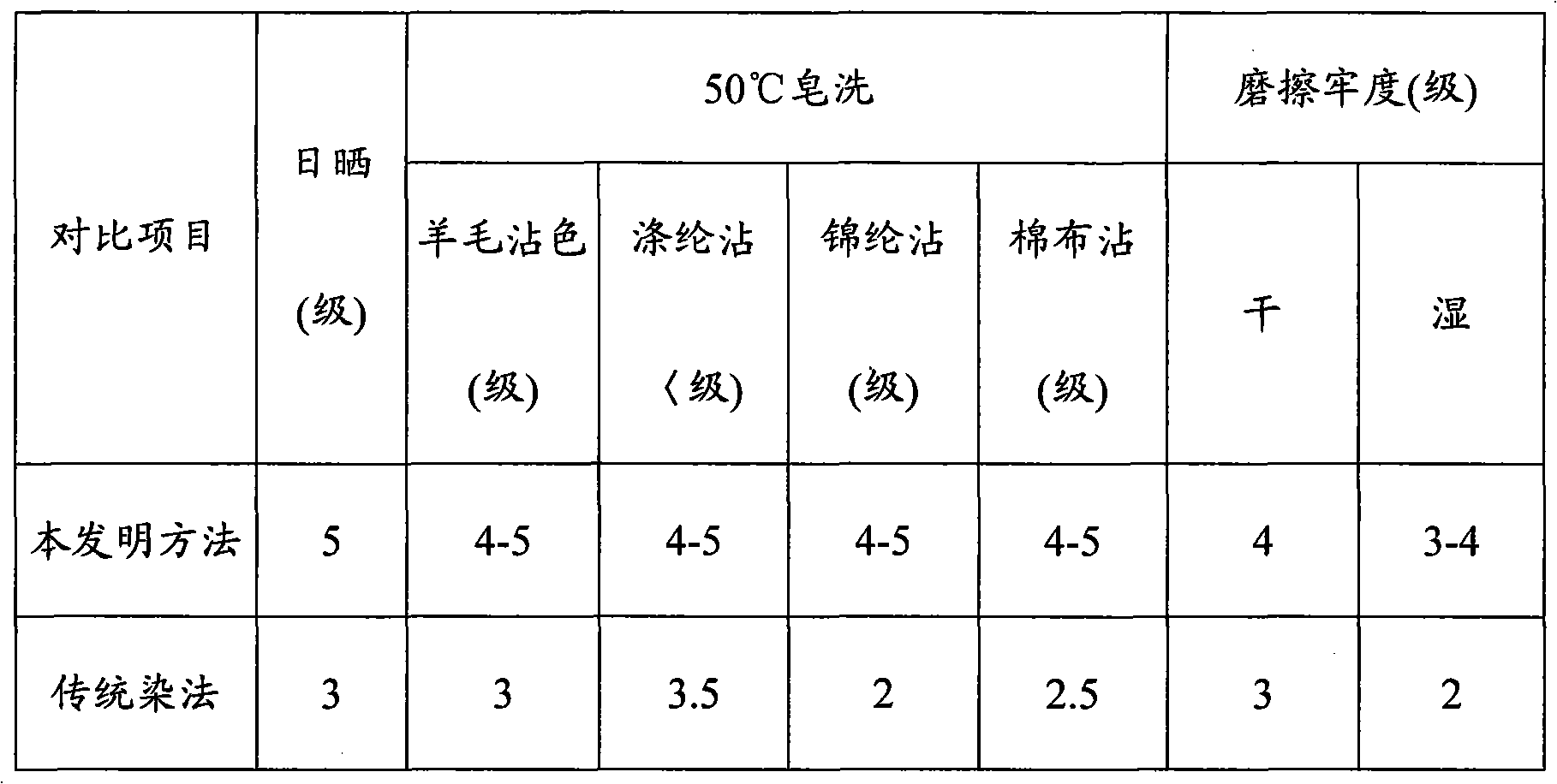

[0059] Polyamide / polyurethane synthetic leather dyeing process, brushed imitation buckskin synthetic leather composed of 0.1 denier superfine polyamide fiber 75% / polyurethane 25% (weight percentage), unit weight 500g / m 2 , Dye brown with C.I.Pigment Brown 23#.

[0060] Penetration aid preparation (by weight):

[0061] Lauryl Azone 0.0004

[0062] Tetradecyl Betaine 20.0

[0063] Dipropylene glycol methyl ether 4

[0064] N-methylpyrrolidone 4

[0065] Tri-n-butyl phosphate 2.0

[0066] Butyl ether 50.0006

[0067] Benzyl alcohol 18.0

[0068] Ammonium lignosulfonate 1.0

[0069] The penetration aid is mixed according to the above components in parts by weight, and is ready for use, hereinafter referred to as SSD-1.

[0070] Solubilization and dispersion of pigments:

[0071] Pigment: SSD-1 = 1:1 (weight ratio) beating, the pigment is solubilized and dispersed into a liquid suspension state from the original water-insoluble state, that is, 8kg of pigment brown c.1.23#,...

Embodiment 2

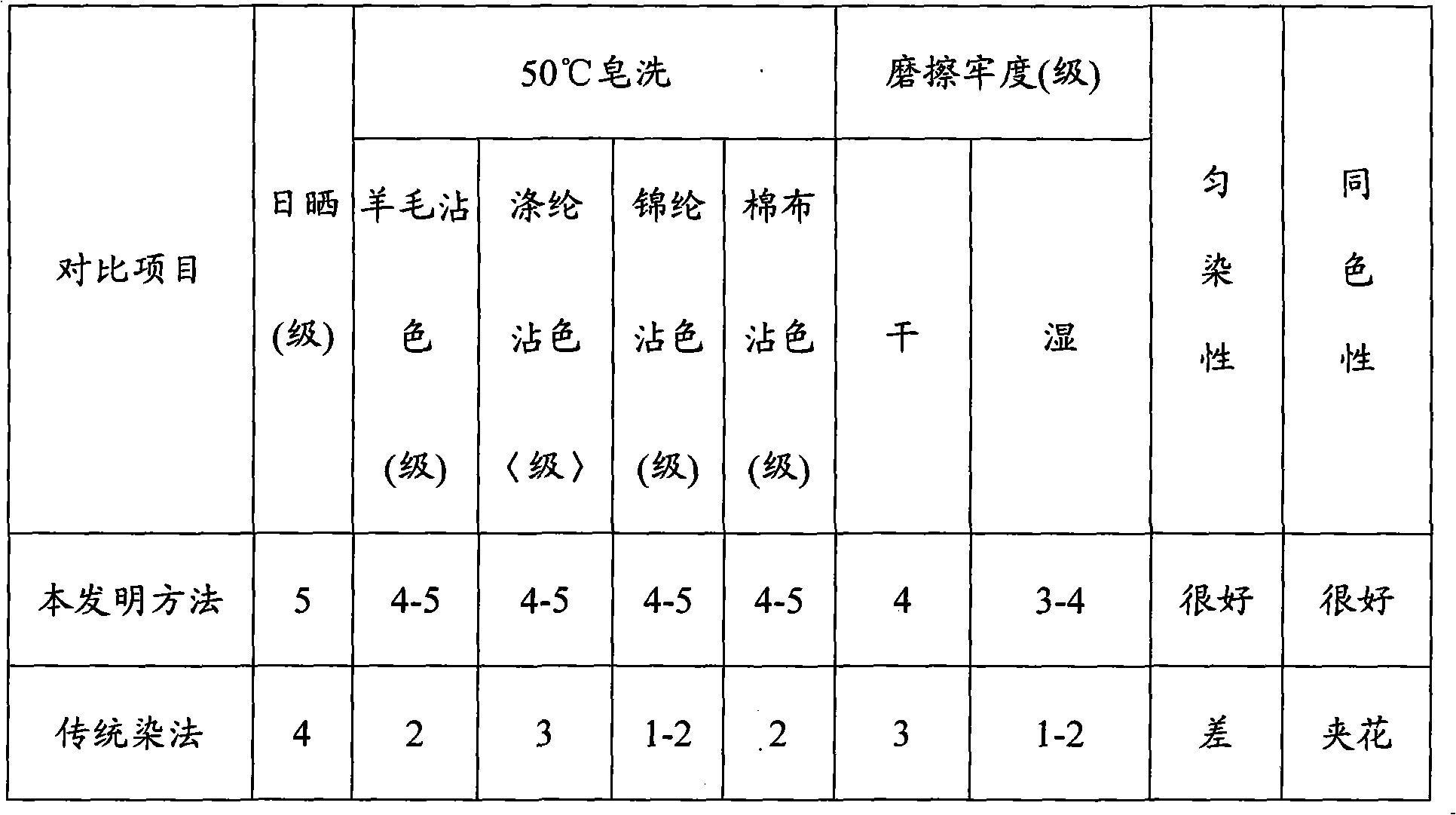

[0076] Synthetic leather composed of polyester fiber and polyurethane, unit weight 700g / m 2 , with Pigment Green 6#, the dyeing process is as follows:

[0077] Penetration aids are formulated in the following parts by weight:

[0078] 3-hydroxy-2-butanone 6

[0079] Diacetone Alcohol 15

[0080] Lauryl Azone 0.0002

[0081] Tetradecyl Betaine 15

[0082] Dipropylene glycol methyl ether 2

[0083] N-Methylpyrrolidone 3

[0084] Tri-n-butyl phosphate 1.5

[0085] Diethylene glycol 21

[0086] β-naphthol polyoxyethylene ether (wherein the molar number of oxyethylene n=10) 10

[0087] Methoxybenzyl alcohol 1.5

[0088] Benzyl alcohol 5

[0089] Ammonium lignosulfonate 2

[0090] Mix and prepare SSD-2 according to the weight parts of the above components, and set aside;

[0091] The gray fabric was washed in a dyeing vat at 60°C for 30 minutes before washing, and was mixed with SSD-2 and Defoaming King (Shanghai Lilei Chemical Auxiliaries Company) for polyester disperse...

Embodiment 3

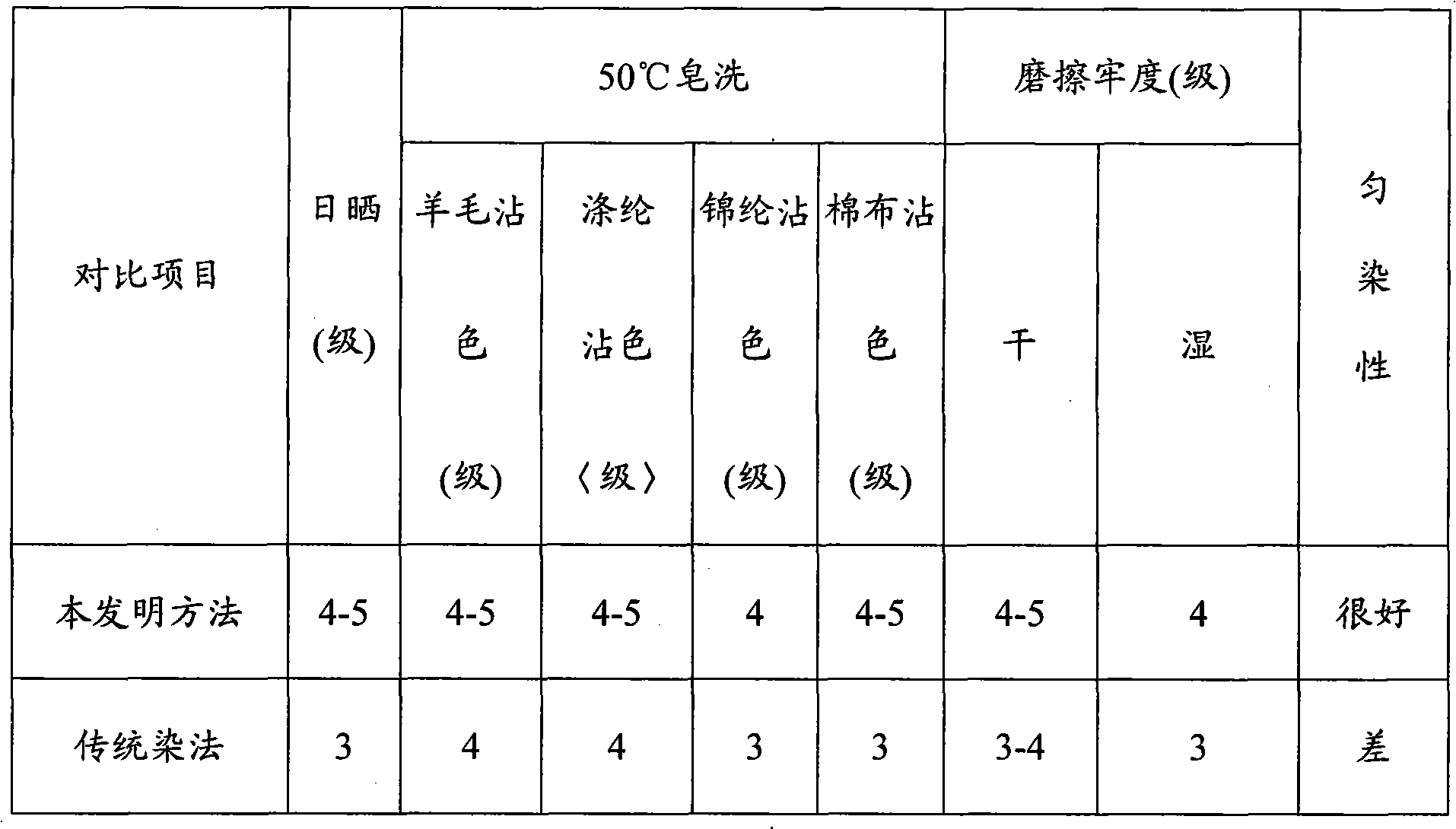

[0098] Hemp degumming process

[0099] The penetration aid is proportioned according to the following parts by weight

[0100] 3-hydroxy-2-butanone 3

[0101] Diacetone Alcohol 10

[0102] Lauryl Azone 0.0002

[0103] Tetradecyl Betaine 15

[0104] Dipropylene glycol methyl ether 3

[0105] N-methylpyrrolidone 5

[0106] Tri-n-butyl phosphate 1.5

[0107] Diethylene glycol or butyl ether 21

[0108] Benzyl alcohol 10

[0109] Ammonium lignosulfonate 2

[0110] Mix and prepare SSD-3 according to the weight parts of the above components, and set aside;

[0111] Soak the hemp with plant stem husk residue in water 20 times the weight of hemp, add 35% H 2 o 2 to H in water 2 o 2 The concentration of the solution reaches 10ml / L, then the pH of the bath solution is adjusted to 11.0 with NaOH, and the penetration aid SSD-3 is added until the concentration of SSD-3 in the solution reaches 2.5-5.0g / L, treated at 85°C for 60 minutes, and then washed ;

[0112] Put the hemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com