Silk broadcloth anti-water anti-oil dressing agent, preparation method and uses thereof

A water- and oil-repellent, silk-repellent technology, applied in the water-repellent finishing agent on the surface of real silk, the functional modification of real silk, and the field of preparation, can solve the problems of unsatisfactory hand feeling, no oil-proof, anti-fouling, etc. The effect of broadening the application, improving the wearing performance and improving the durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of finishing agent:

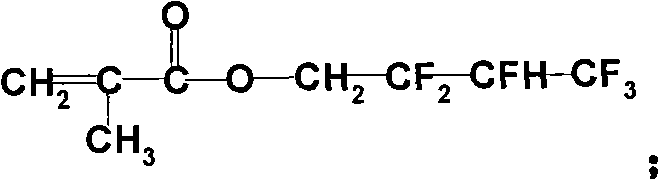

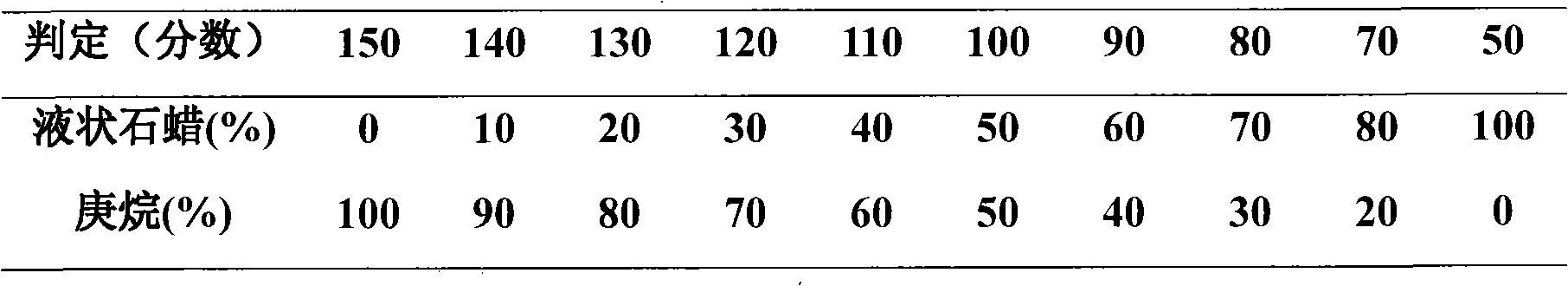

[0026] The vinyl fluorine-containing monomer used in this embodiment is hexafluorobutyl methacrylate, and the amounts are respectively 50%, 100%, and 200% of the power spinning weight of real silk.

[0027] The emulsifier is a combination of the following three surfactants:

[0028] Ethoxylated non-ionic fluorocarbon surfactant, the addition amount is 10% of the weight of hexafluorobutyl methacrylate monomer;

[0029] N-alkyl perfluorooctyl sulfonamide or N-hydroxyalkyl perfluorooctyl sulfonamide surfactant, the addition amount is 6% of the weight of hexafluorobutyl methacrylate monomer;

[0030] The non-ionic surfactant Tween 80 is added in an amount of 20% of the weight of the hexafluorobutyl methacrylate monomer.

[0031] Preparation of finishing agent:

[0032] Dissolve the emulsifier in water, stir at a high speed of 9000r / min for 1min on a high-speed emulsifier, and then increase the speed to 12000r / min. Under the condition of high-sp...

Embodiment 2

[0040] Preparation of finishing agent:

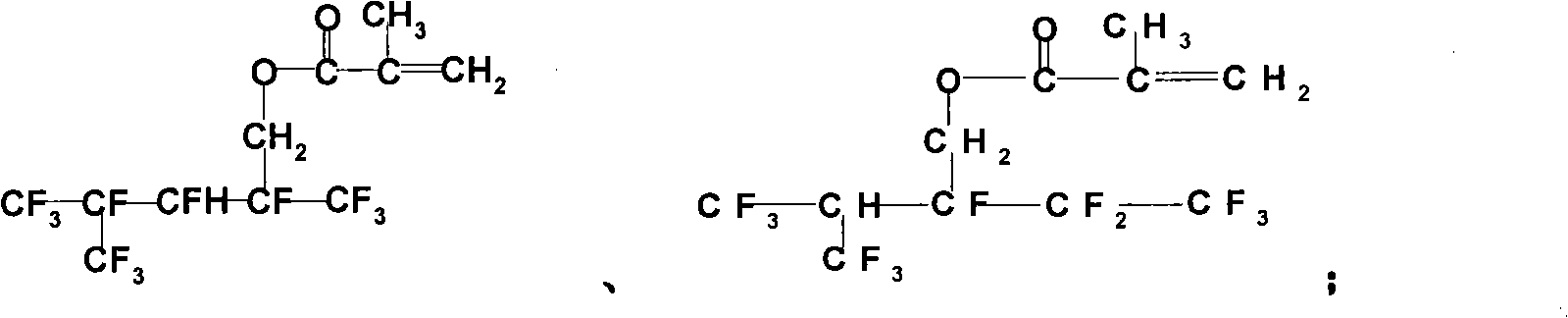

[0041] The vinyl fluorine-containing monomer used in this embodiment is dodecafluoroheptyl methacrylate, and the amounts are respectively 20%, 40%, and 60% of the power spinning weight of real silk.

[0042] The emulsifier is a combination of the following three surfactants:

[0043] Ethoxylated non-ionic fluorocarbon surfactant, the product used is FSO from DuPont of the United States, and the addition amount is 12% of the weight of dodecafluoroheptyl methacrylate monomer;

[0044] N-alkyl, N-hydroxyalkyl perfluorooctyl sulfonamide, the product used is DF-10 from Wuhan Changjiang Chemical Plant, and the addition amount is 8% of the weight of dodecafluoroheptyl methacrylate monomer;

[0045] The nonionic surfactant Tween 80 is added in an amount of 20% of the weight of the dodecafluoroheptyl methacrylate monomer.

[0046] Preparation of finishing agent:

[0047] Dissolve the emulsifier in water, stir on a high-speed emulsifier at a speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com