Continuous automatic pug mixer

A sand mixer and sand mixing technology, which is applied in the field of sand mixers and sand mixers in foundry machinery, to achieve the effects of stable flow and pressure ratio, accurate quantification, and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

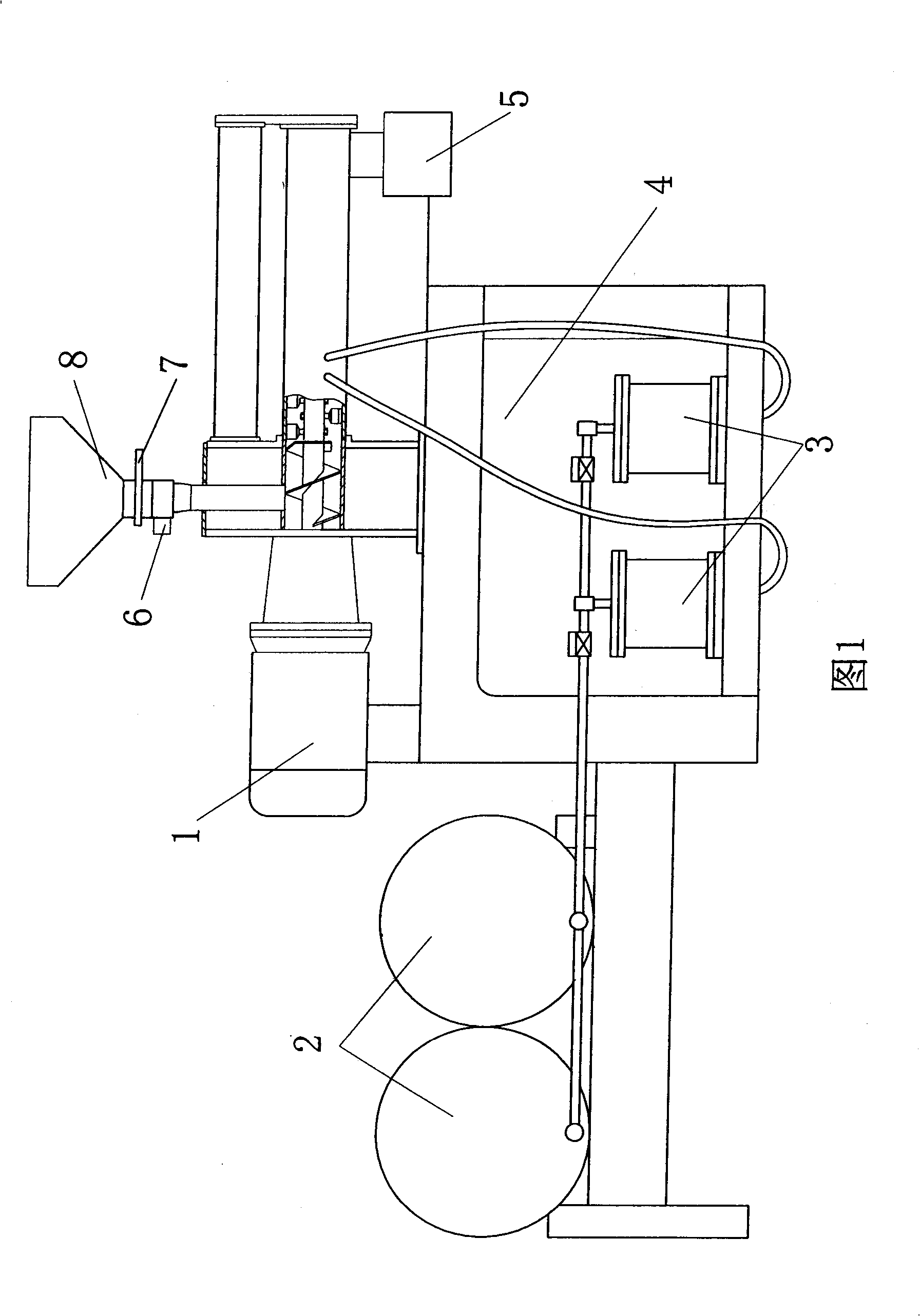

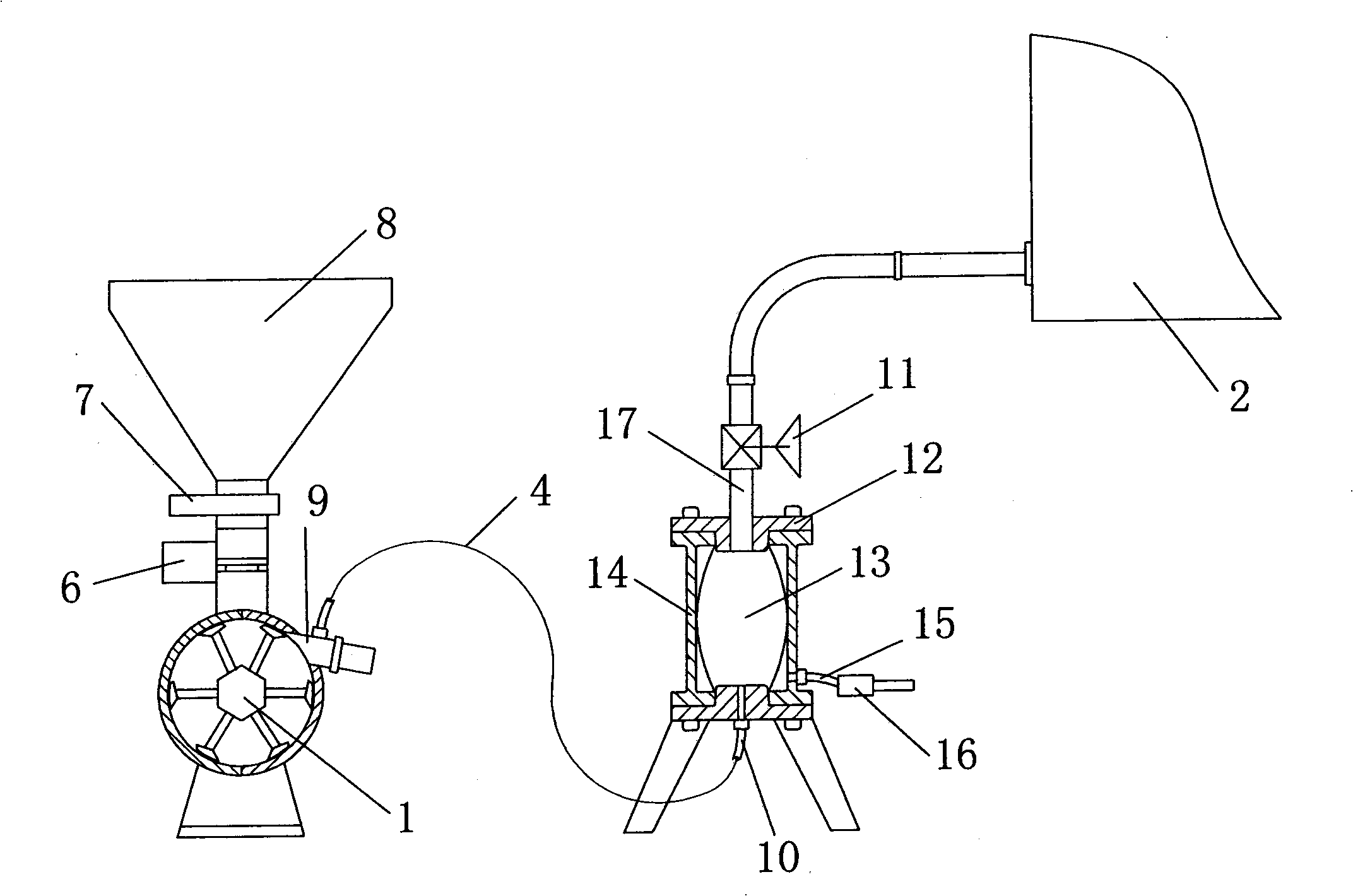

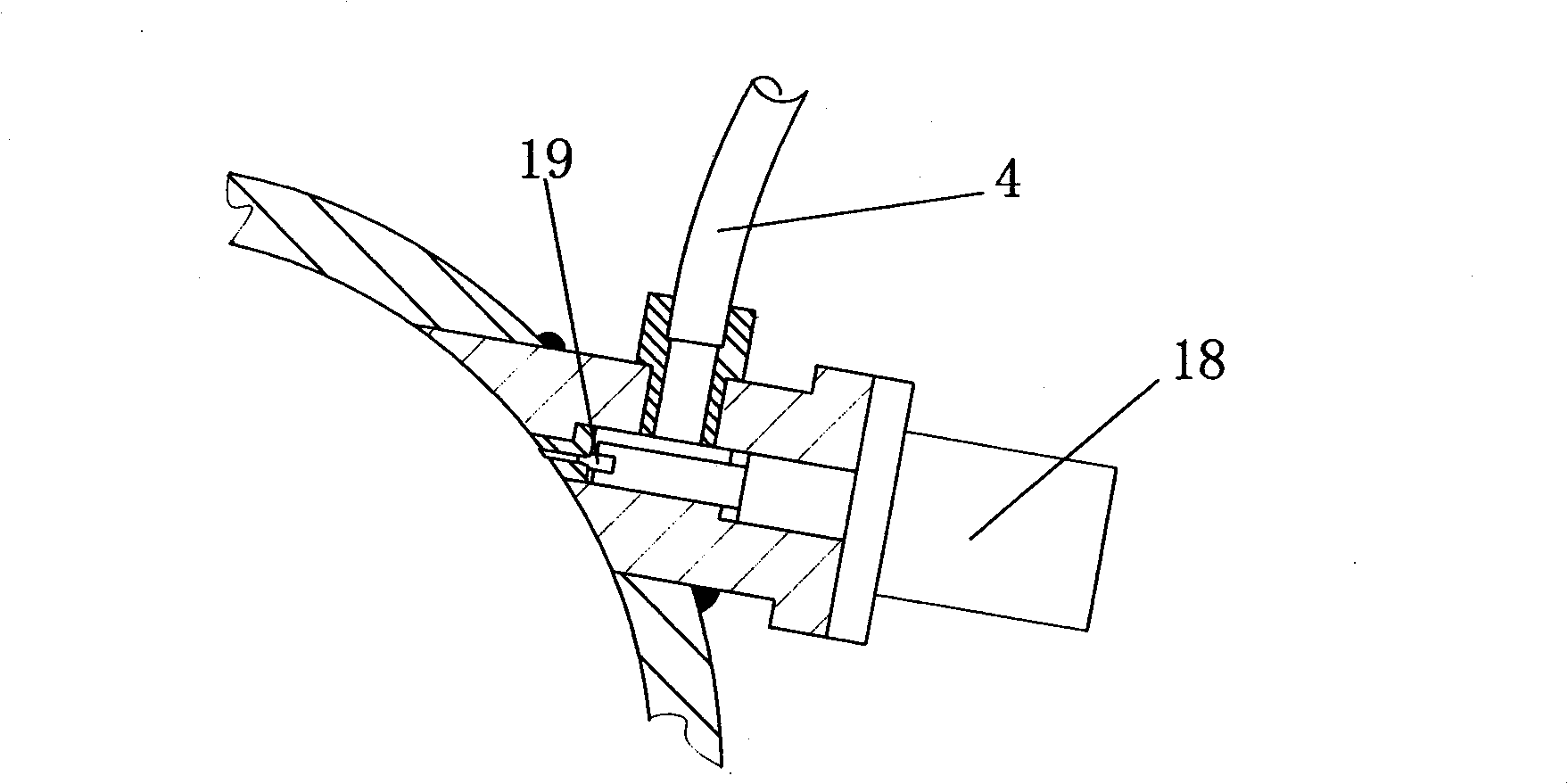

[0014] As shown in Figure 1, the continuous automatic sand mixer of the present invention includes a sand mixing cage 1, a dry sand bin 8 and a closed resin quantitative device 3, the sand mixing cage 1 adopts an existing structure, and its feed port passes through a flexible cloth bag It is connected with the lower port of the dry sand bin 8, and the lower port of the dry sand bin 8 is equipped with a pneumatic sand adding valve 6 and a proportional control valve 7. The pneumatic sand adding valve 6 is used to control adding sand to the sand mixing and stirring cage 1, and the proportional control valve 7 is used to control the opening size during sand falling and control the flow of sand. A funnel 5 is provided at the outlet of the sand mixing and stirring cage 1 . A resin feed valve 9 is provided on the housing of the sand mixing and stirring cage 1 . The closed resin quantitative device 3 is connected with the resin feed valve 9 on the sand mixing and stirring cage 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com