Cationic aqueous epoxy resin grouting material and preparation thereof

A water-based epoxy resin and cationic technology, which is applied in the field of polymer materials, can solve problems such as the application of cationic polymers that have not been reported, and achieve good bonding performance, good stability, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

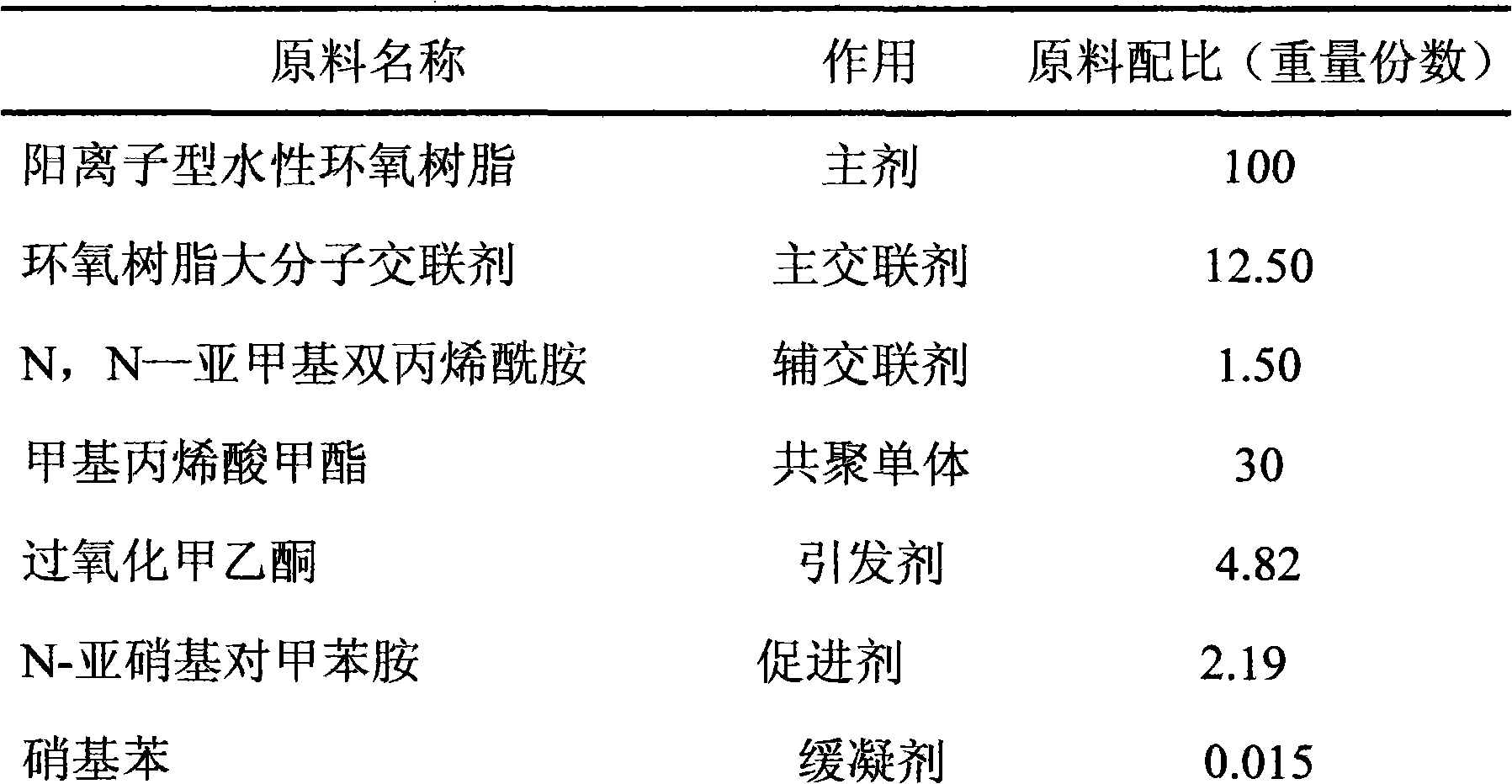

Embodiment 1

[0048] (1) Preparation of cationic waterborne epoxy resin:

[0049] In a four-neck flask equipped with a stirrer, a reflux condenser, a thermometer and a nitrogen inlet, add 152.00 g (0.776 mol epoxy) of epoxy resin (E-51), 22.8 g cosolvent (10.8 g methacrylic acid Hydroxyethyl ester and 12g ethylene glycol monobutyl ether), 0.52g hydroquinone, nitrogen gas is passed through to remove the air, and the temperature is raised to 60°C to completely dissolve E-51.

[0050] Then 33.85g (0.350mol) of diallylamine was added dropwise, and the temperature was kept between 60-70°C, and the drop was completed within 1 hour. After the dropwise addition, the temperature was raised to 75-80°C, and the reaction was continued for 2.5 hours.

[0051] Then lower the temperature of the reaction system to 60°C, add 0.24g of hydroquinone, add dropwise 44.78g (0.427mol) of diethanolamine, keep the temperature between 60-70°C, drop it within 1 hour, after the dropwise addition, raise the temperature ...

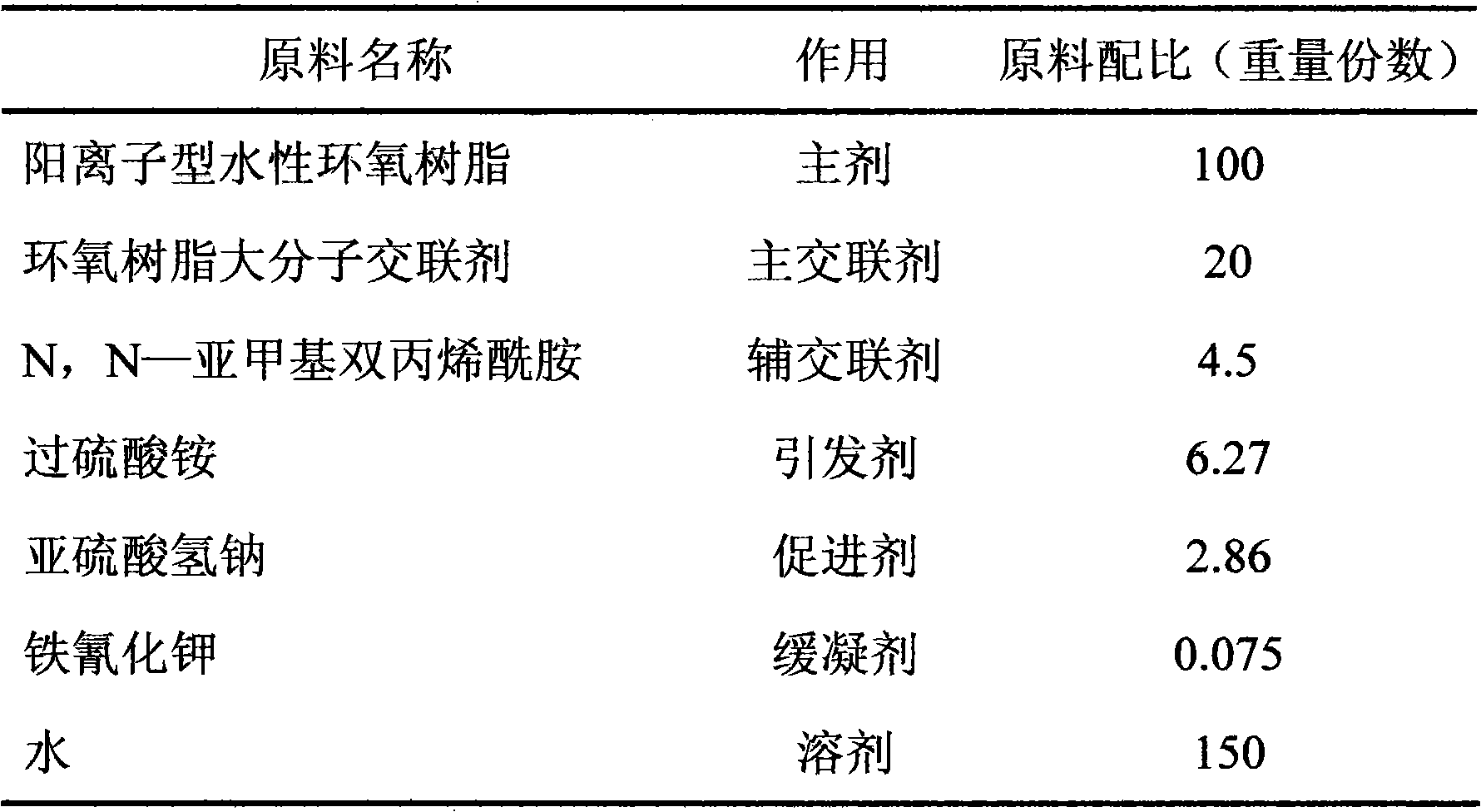

experiment example 2

[0060] (1) Preparation of cationic waterborne epoxy resin:

[0061] In a four-neck flask equipped with a stirrer, a reflux condenser, a thermometer and a nitrogen inlet, add 162.52 g (0.829 mol epoxy) of epoxy resin (E-51), 39.2 g of cosolvent (hydroxyethyl methacrylate Esters), 0.43g of 2,6-di-tert-butyl-p-cresol, nitrogen gas was passed through to remove the air, and the temperature was raised to 60°C to completely dissolve E-51.

[0062] Then 40.21g (0.414mol) of diallylamine was added dropwise, and the temperature was kept between 60-70°C, and the drop was completed within 1 hour. After the dropwise addition, the temperature was raised to 75-80°C, and the reaction was continued for 3.5 hours.

[0063] Then lower the temperature of the reaction system to 60°C, add 0.22g of 2,6-di-tert-butyl-p-cresol, dropwise add 46.52g (0.443mol) of diethanolamine, keep the temperature between 60-70°C, and finish the drop within 1 hour. After the dropwise addition, the temperature was rai...

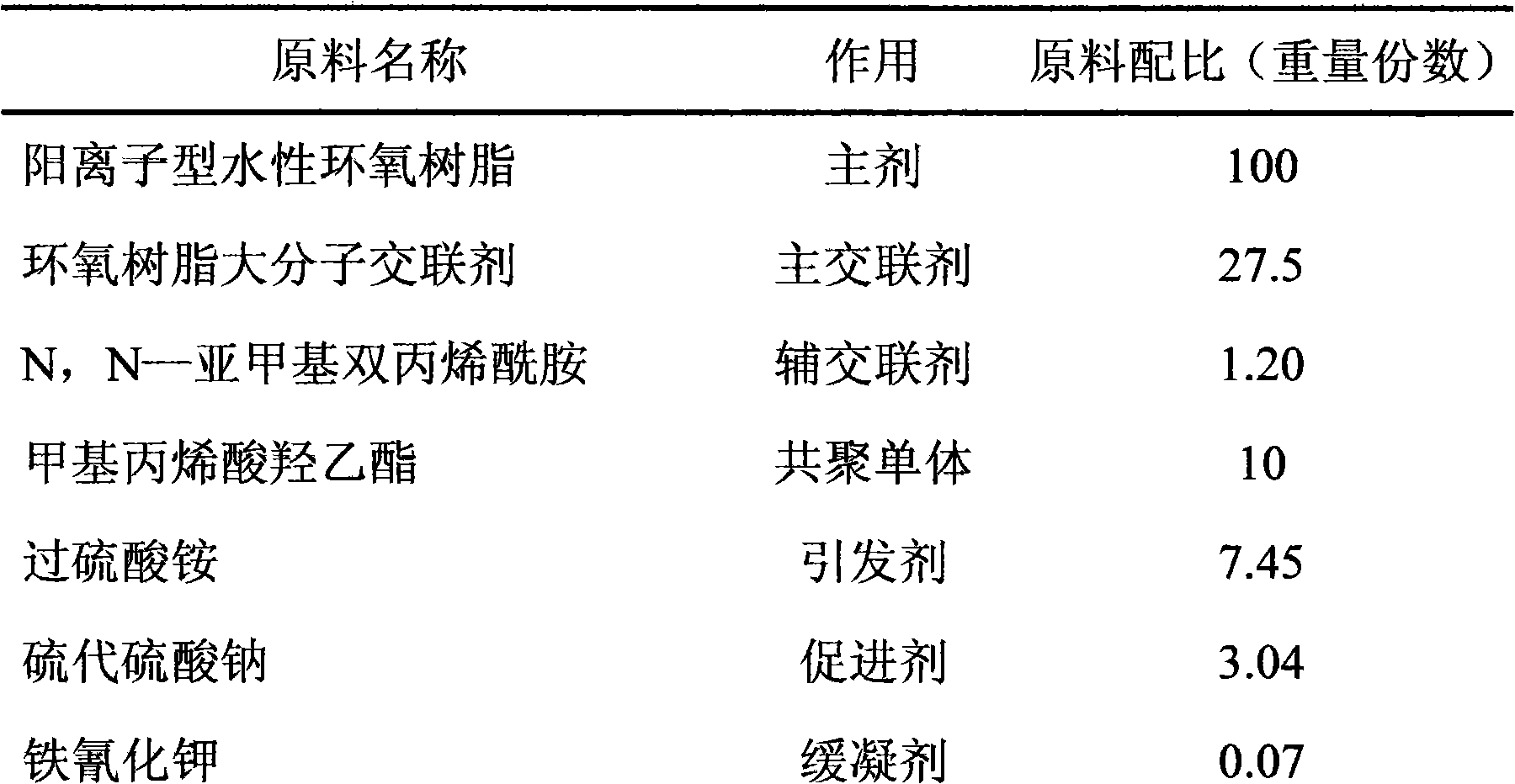

experiment example 3

[0072] (1) Preparation of cationic waterborne epoxy resin:

[0073] In a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer and a nitrogen inlet, add 144.26 g (0.736 mol epoxy) of epoxy resin (E-51), 28.85 g of cosolvent (15.25 g of methacrylic acid Hydroxyethyl ester and 13.6g n-butanol), 0.21g 2,6-di-tert-butyl-p-cresol, nitrogen gas was passed through to remove the air, and the temperature was raised to 60°C to completely dissolve E-51.

[0074] Then 35.70g (0.368mol) of diallylamine was added dropwise, and the temperature was kept between 60-70°C, and the drop was completed within 1 hour. After the dropwise addition, the temperature was raised to 85-90°C, and the reaction was continued for 2.5 hours.

[0075] Then cool down the reaction system to 60°C, add 0.22g of 2,6-di-tert-butyl-p-cresol, dropwise add 40.57g (0.386mol) of diethanolamine, keep the temperature between 60-70°C, and drop it within 1 hour. After the dropwise addition, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com