Process for preparing rubber accelerator TBBS

A technology of rubber accelerator and production method, applied in organic chemistry and other directions, can solve the problems of large distillation load, large amount of waste water and high COD, and achieve the effects of reducing waste water discharge, saving energy and improving M conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

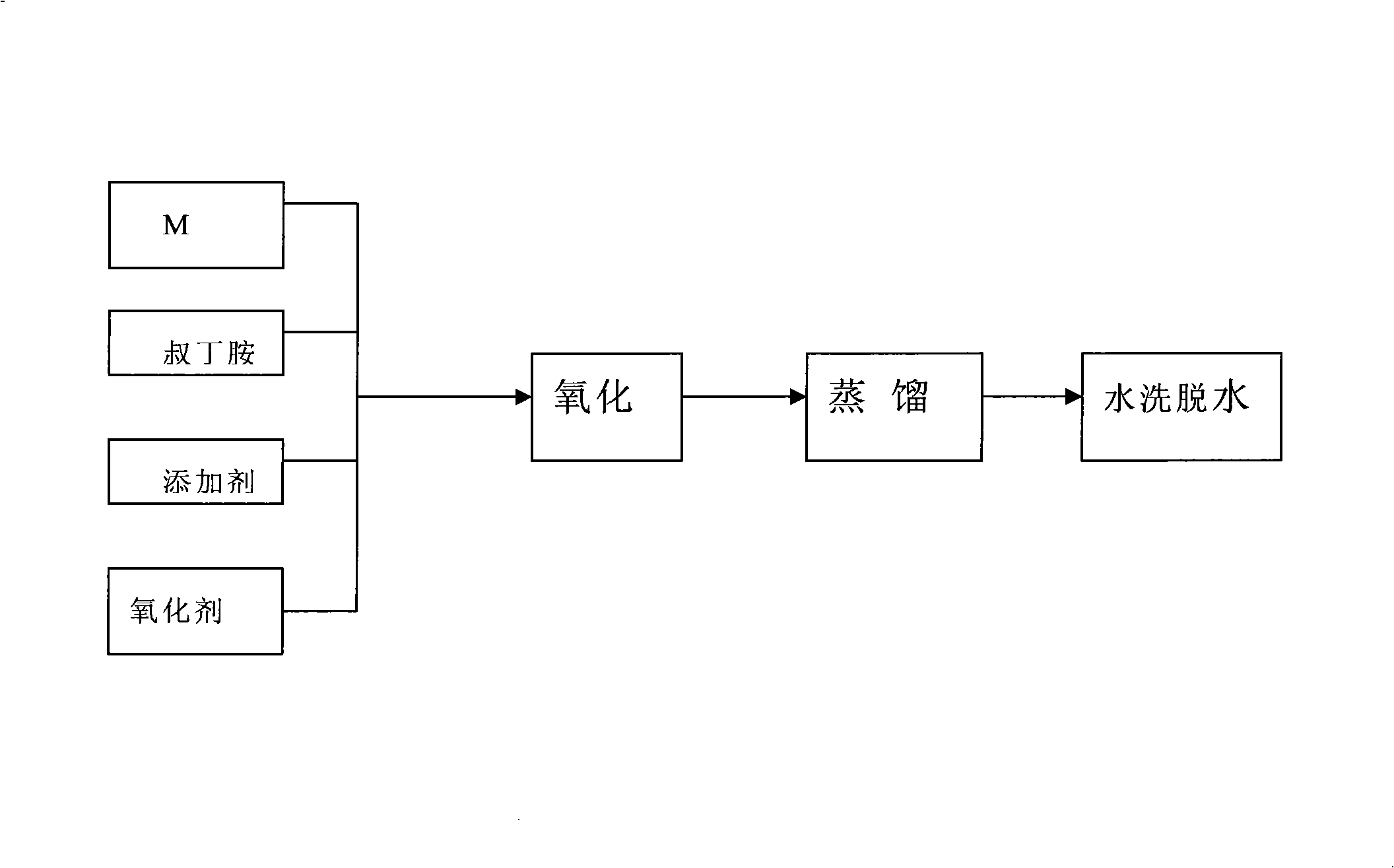

Image

Examples

Embodiment 1

[0015] The production method of rubber accelerator TBBS of the present invention is made up of following steps successively:

[0016] a, oxidation reaction: with 500 kilograms of raw materials M, 600 kilograms of tert-butylamine and 0.5 kilogram of carbonic acid, add 5500 kilograms of water and stir evenly, keep the temperature in the oxidation kettle at 30-50 ℃, add 436 kilograms of hydrogen peroxide solution with a mass content of 28% (hydrogen peroxide molecular weight: 34.01) was oxidized, and the oxidation time was 7 hours;

[0017] b. The oxidized material is distilled to recover tert-butylamine: adopt the vacuum distillation method, the vacuum degree is 0.03-0.09MPa, the temperature at the top of the tower is 20-25°C, the temperature at the bottom of the tower is 20-25°C, and the distillation time is 5 hours;

[0018] c. The remaining material after distillation is placed in a centrifuge and washed with water in a conventional manner until pH = 7 to obtain a finished pr...

Embodiment 2

[0021] The production method of rubber accelerator TBBS of the present invention is made up of following steps successively:

[0022] a, oxidation reaction: with 500 kilograms of raw materials M, 2000 kilograms of tert-butylamine and 50 kilograms of acetic acid, add 7500 kilograms of water and stir evenly, keep the temperature in the oxidation kettle at 30-50 ° C, add 654 kilograms of hydrogen peroxide solution with a mass content of 28% (hydrogen peroxide molecular weight: 34.01) is oxidized, and the oxidation time is 3 hours;

[0023] b. The oxidized material is distilled to recover tert-butylamine: adopt the vacuum distillation method, the vacuum degree is 0.03-0.09MPa, the temperature at the top of the tower is 60-65°C, the temperature at the bottom of the tower is 75-80°C, and the distillation time is 2 hours;

[0024] c. The remaining material after distillation is washed with water in a centrifuge until pH = 7 to obtain the finished product of TBBS.

[0025] All the ot...

Embodiment 3

[0027] The production method of rubber accelerator TBBS of the present invention is made up of following steps successively:

[0028] a. Oxidation reaction: Add 500 kg of raw material M, 1300 kg of tert-butylamine and 25 kg of oxalic acid, add 6500 kg of water and stir evenly, keep the temperature in the oxidation kettle at 30-50 ° C, add 550 kg of hydrogen peroxide solution with a mass content of 28% for oxidation , the oxidation time is 5 hours;

[0029] b. Distillation of the oxidized material to recover tert-butylamine: adopt vacuum distillation method, the vacuum degree is 0.03-0.09MPa, the temperature at the top of the tower is 40-45°C, the temperature at the bottom of the tower is 50-55°C, and the distillation time is 3.5 hours;

[0030] c. The remaining material after distillation is washed with water in a centrifuge until pH = 7 to obtain the finished product of TBBS.

[0031] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com