Preparation method for impact resistant ecological concrete

An ecological concrete, impact-resistant technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor impact resistance, and achieve good impact resistance, good construction performance, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

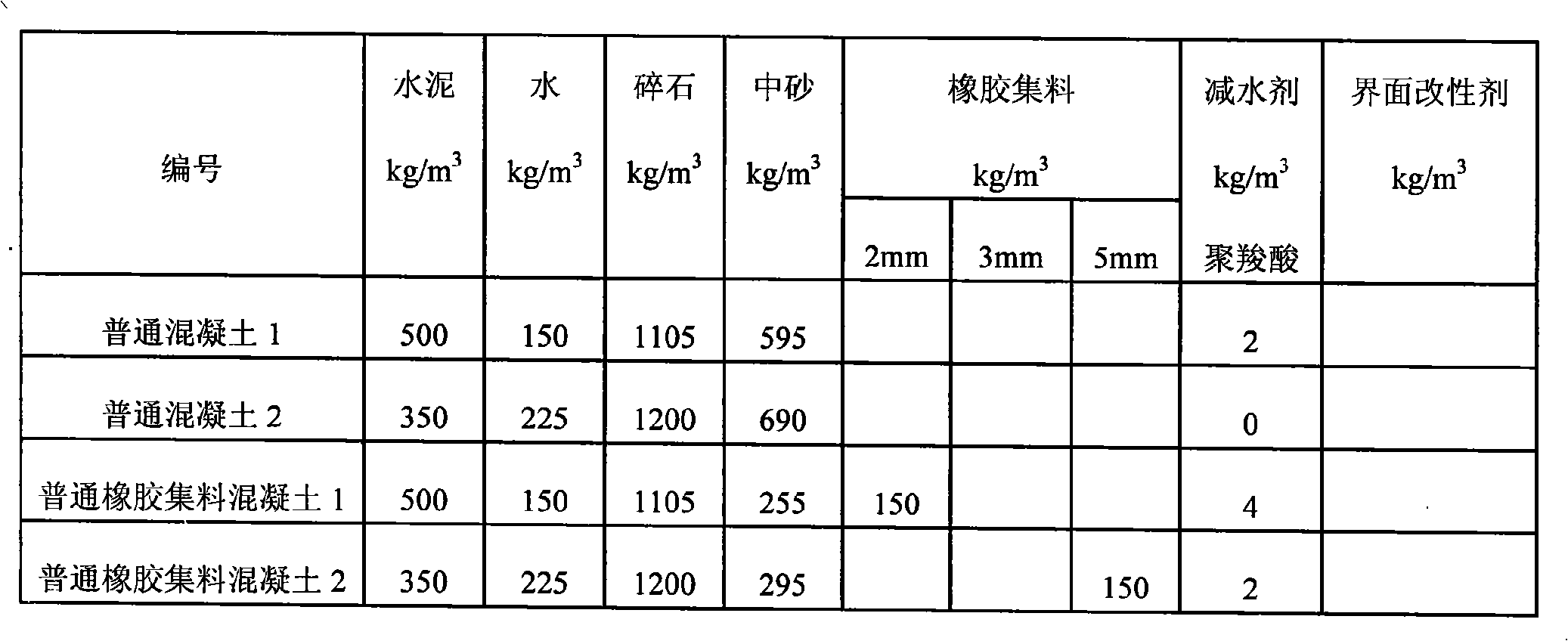

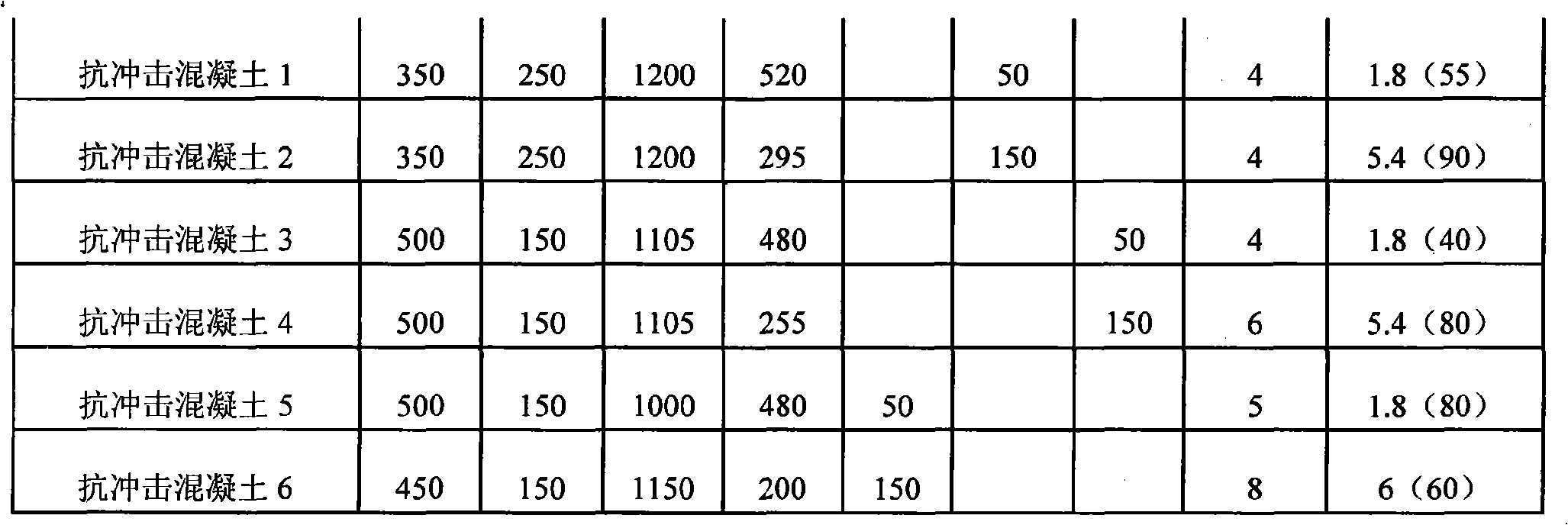

[0025] The mix ratio (the weight of various materials in every cubic meter of concrete, unit kg / m) as the benchmark ordinary concrete of contrast, the ordinary rubber aggregate concrete that is not processed by interface modifier and the impact-resistant rubber aggregate concrete of the present invention 3 ) and impact resistance are shown in Table 1 and Table 2. The cement is P.O42.5 ordinary Portland cement, the sand is medium sand with a fineness modulus of 2.8, the gravel is continuously graded crushed stone of 5-25mm, and the average particle size of the rubber aggregate is 2mm, 3mm and 5mm. The high-efficiency water reducer is a polycarboxylic acid-based high-efficiency water reducer. The specific implementation method is as described above.

[0026] The impact test method adopts the bending impact test method, and the size of the test pieces for the bending impact test is 100mm×100mm×400mm, with 6 test pieces in each group. The free fall hammer is a solid cylinder wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com