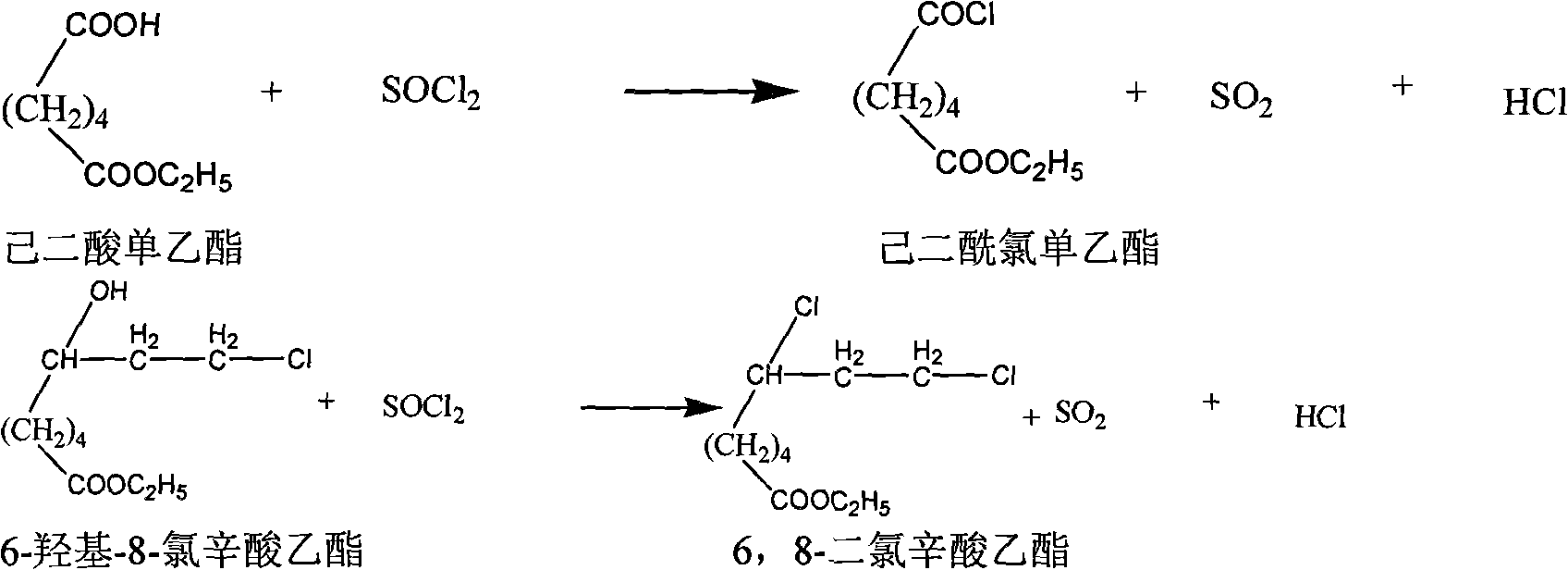

Recovery method for mix waste gas of hydrogen chloride and sulphur dioxide in lipoic acid preparation

A technology of sulfur dioxide and recovery method, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, preparation of alkali metal sulfite, etc., which can solve the problems of waste of resources, comprehensive utilization without seizure, and increase of self-cost, and achieve saving production Cost, beneficial to maximize the use of resources, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

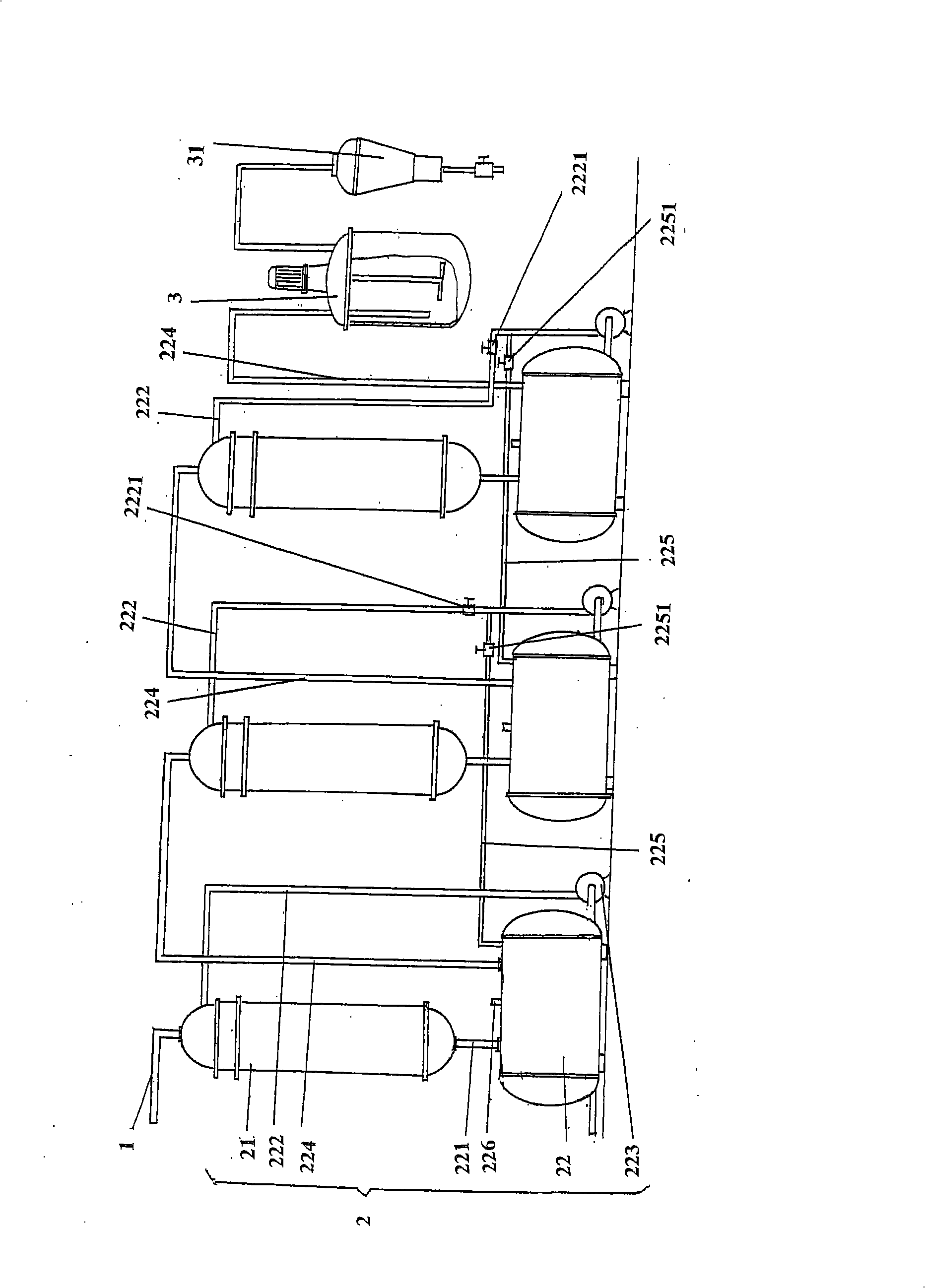

[0020] Please refer to the accompanying drawings, the hydrogen chloride and sulfur dioxide mixed waste gas produced by the sulfur oxychloride chlorination reaction produced by the lipoic acid intermediate reducing solution and the acylating solution in the acylchlorination process are introduced into the water absorption device 2 by pipeline 1, In this embodiment, the applicant selected three sets of water absorption devices 2 connected in series for dissolving hydrogen chloride gas in water. According to the common technical knowledge familiar to the industry, hydrogen chloride gas is easily soluble in water, while sulfur dioxide is hardly soluble in water. The applicant implemented the recovery based on this principle. Each set of water absorption device 2 includes an absorption tower 21 and a storage tank 22 connected to the absorption tower 21 through the first and second pipelines 221, 222. When the mixed exhaust gas of hydrogen chloride and sulfur dioxide enters the first...

Embodiment 2

[0026] Control step-by-step reaction conditions: the concentration of sodium hydroxide is 10%, the reaction temperature is 40°C, adjust the pH to 5.0; in another reaction kettle, the concentration of sodium hydroxide is 10%, the reaction temperature is 40°C, adjust the pH to 9.0 , the content of the sodium sulfite heptahydrate obtained is 48.7%, meets the requirements of the national standard first-class product, and all the other are the same as the description to embodiment 1.

Embodiment 3

[0028] Control the step-by-step reaction conditions: the concentration of sodium hydroxide is 10%, the reaction temperature is 50°C, and the pH is adjusted to 6.0; when the reaction solution is switched from reactor 3 to another reactor, the concentration of sodium hydroxide is 10%, and the reaction temperature is 10%. 50 DEG C, adjust the pH to 9.5, the content of the obtained sodium sulfite heptahydrate is 48.3%, which meets the requirements of the national standard first-class product, and the rest are all the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com