Four-shaft four-linkage numerical control spiral bevel gear milling machine arrangement

A technology of spiral bevel gears and gear milling machines, which is applied in gear tooth manufacturing devices, gear cutting machines, belts/chains/gears, etc. The problem of large land area, etc., achieves the effect of simple structure, reduced floor space, and convenient loading and unloading of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

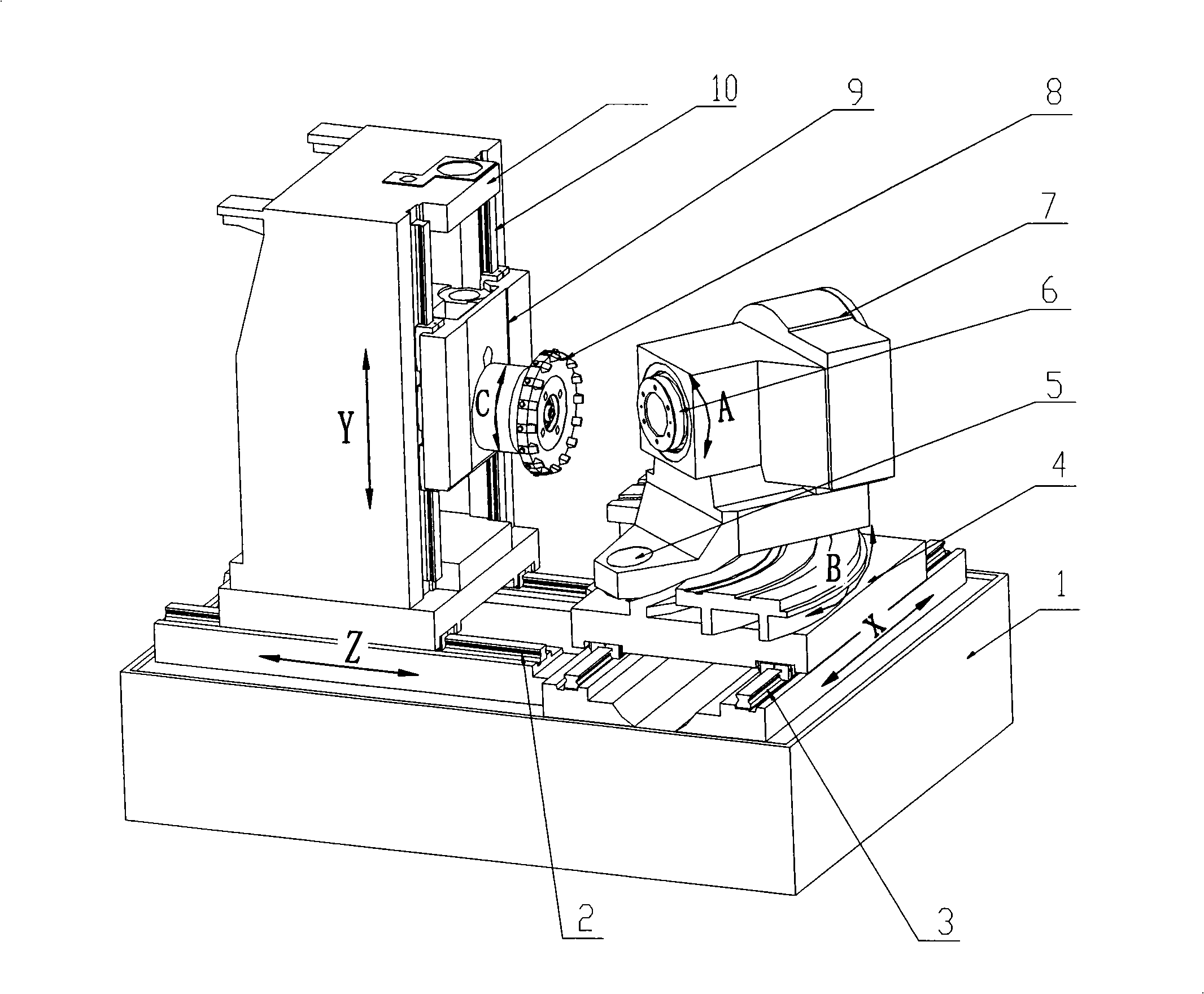

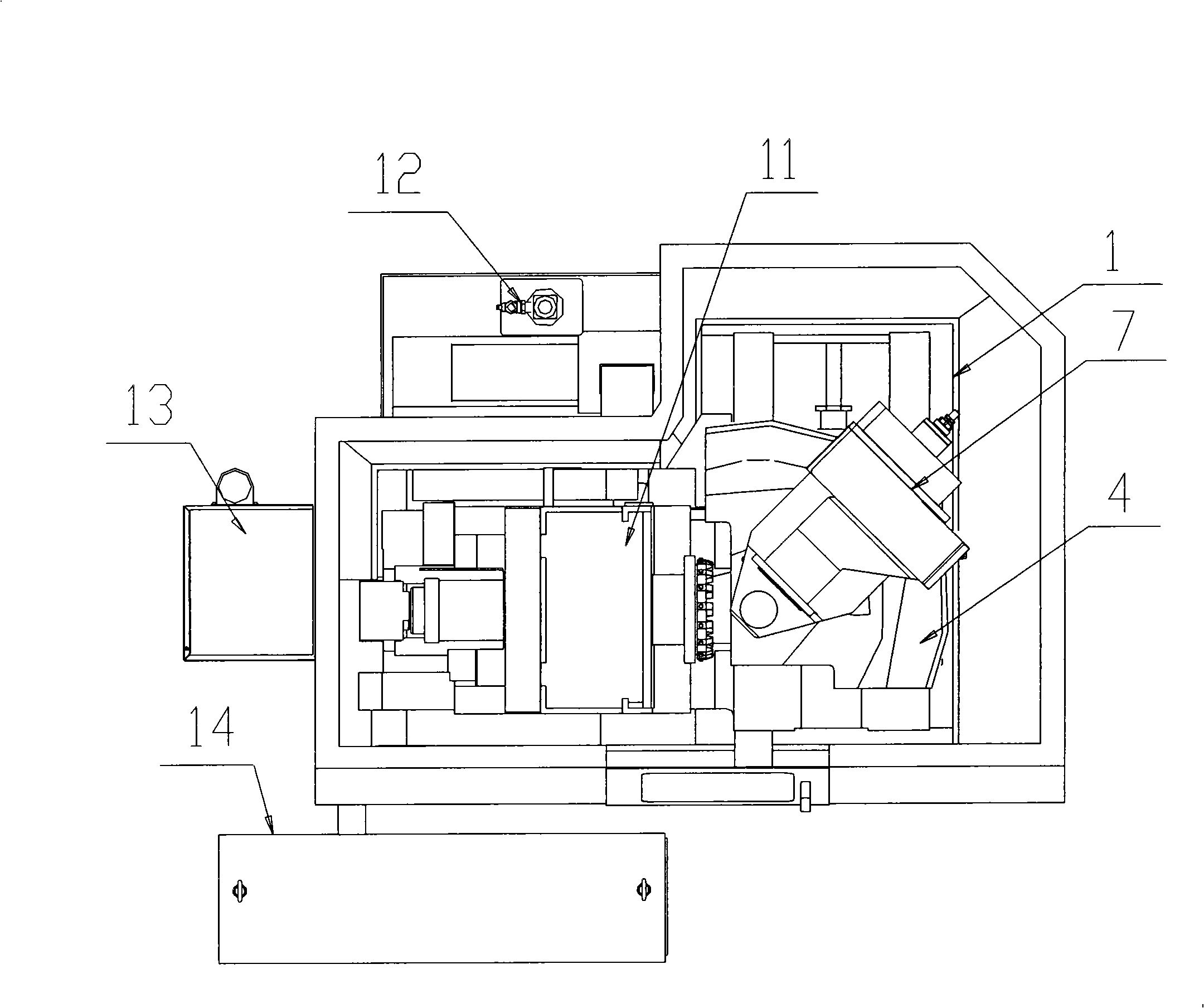

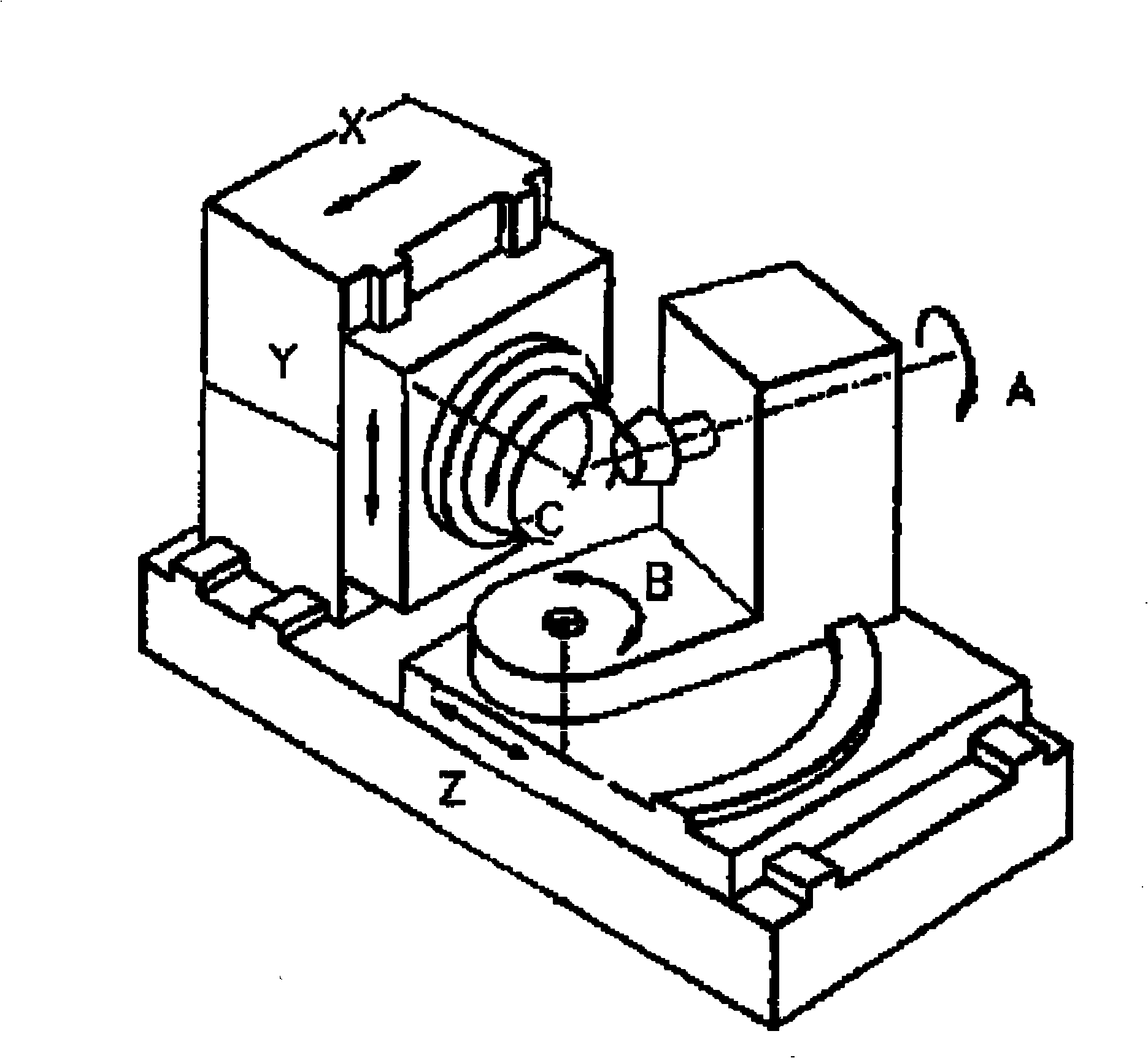

[0022] The layout of the four-axis four-linkage CNC spiral bevel gear milling machine includes a bed 1, a workpiece box 7 and a tool box 9. The bed 1 is equipped with a workpiece box 7 and a tool box 9. The feature is: the bed 1 is fixed The Z-axis linear guide 2 and the X-axis linear guide 3, the X-axis linear guide 3 drives the bed saddle 4 to make a linear motion through the servo motor, the bed saddle 4 is slidingly connected with the bed 1, the bed saddle 4 is provided with a workpiece box 7, and the bed saddle There is a T-shaped groove on 4, and the saddle 4 makes a B-axis rotary motion around the rotary shaft 5, and the rotation range is 0°-90°, and the required gear root taper angle is called out; the workpiece box 7 is provided with a workpiece spindle 6, and a workpiece spindle 6 Driven by the servo motor, the A-axis rotates; the Z-axis linear guide rail 2 drives the column 11 to make a Z-axis linear motion through the servo motor, and the column 11 is in sliding con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com