Method for improving chemical reaction speed in low-temperature condition

A technology of chemical reaction and low temperature conditions, applied in the field of increasing chemical reaction speed under low temperature conditions, can solve problems such as inability to quantify and reproduce, reaction temperature process and poor stability of microwave irradiation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

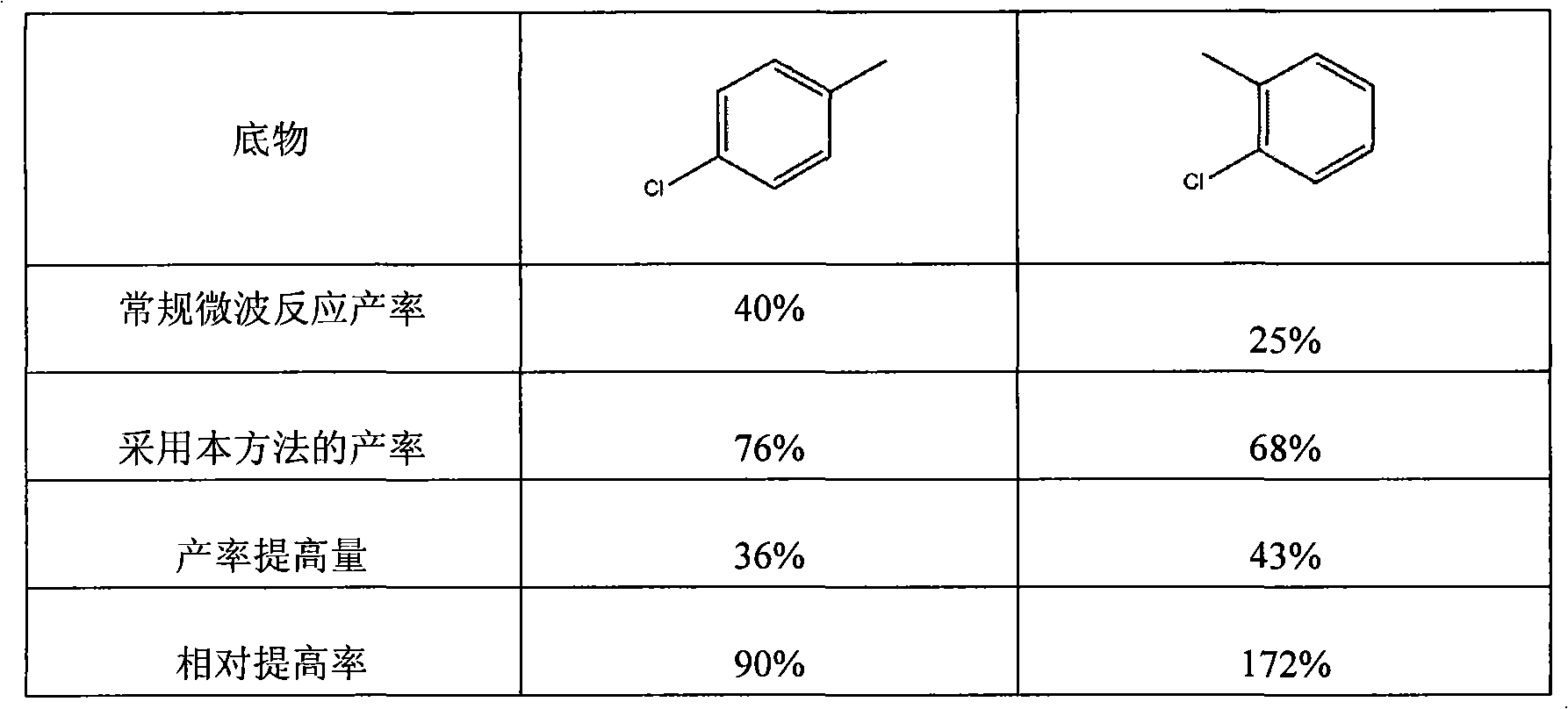

[0029] The present invention is a method for increasing chemical reaction speed under low temperature conditions, and its technical route is mainly reflected in the system design ideas shown in the accompanying drawings. The present invention will be further introduced below in conjunction with the accompanying drawings, but it is not intended to limit the present invention .

[0030] As shown in the accompanying drawing, it is a system block diagram of the present invention. The technical method of the present invention embodied, the refrigerant-microwave irradiation reaction system is the key of this method, it can make the refrigerant circulate rapidly and continuously in the reaction chamber according to the set reaction temperature requirements to control the temperature of the reaction system lower than that of conventional heat The safe temperature of the chemical reaction, and at the same time provide super strong microwave radiation with a frequency of 915MHz or 2450M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com