Organosilicon composite multifunction spinning dressing agent

A multi-functional, silicone technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problem of single function, achieve good softness, good soaping fastness and rubbing fastness, and enhance the effect of moisture absorption and perspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

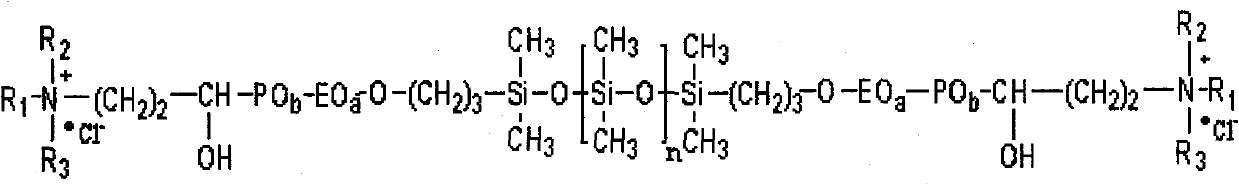

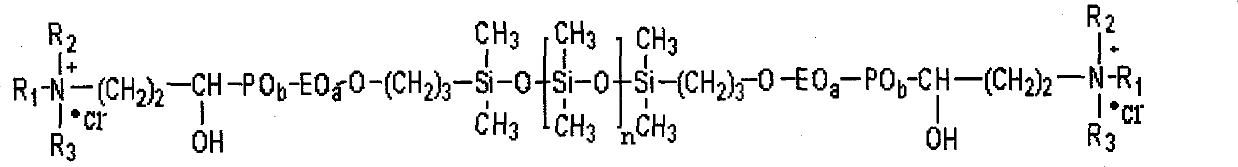

[0043] An organosilicon composite multifunctional textile finishing agent, the structural formula is as follows:

[0044]

[0045] In the formula: n=150; a=14; b=18; R1 is: R2 is: -CH 3 , R3 is: -CH 2 OH,

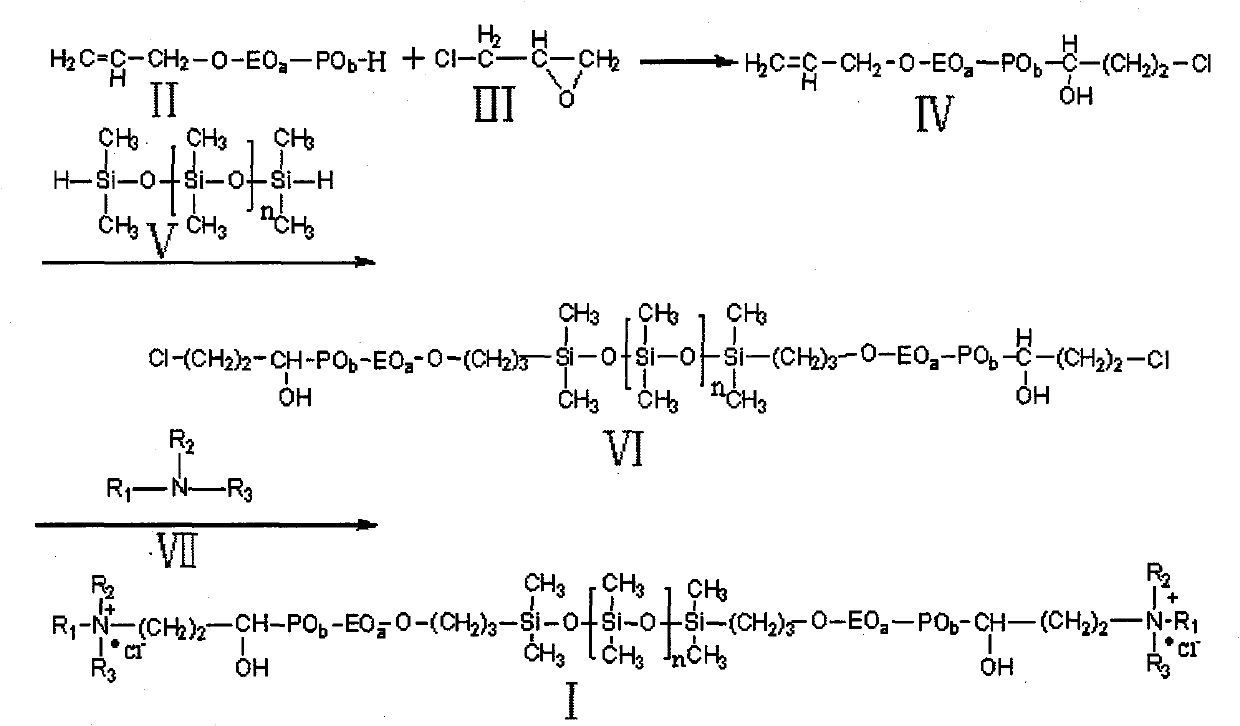

[0046] The steps for preparing the present invention are:

[0047] A. Put the allyl polyether (compound of formula II) with a=14 and b=18 into a four-necked flask, then add tin tetrachloride protective agent at 10°C, stir well, and then add the compound epichlorohydrin dropwise , Which is the compound of formula III, then heated to 90°C and reacted for 3 hours, cooled to below 40°C, centrifuged and filtered, and then purified to obtain a light yellow oily liquid compound, namely the compound of formula IV;

[0048] B. Add the light yellow oily liquid compound (compound of formula IV) prepared in step A, hydrogen-terminated polysiloxane (compound of formula V) with a degree of polymerization of 150 and isopropanol solvent into a four-necked flask, and raise the temperature to 80°C ...

Embodiment 2

[0053] An organosilicon composite multifunctional textile finishing agent, the structural formula is as follows:

[0054]

[0055] In the formula: n=150; a=14; b=18; R1 is: R2 is: -CH 3 R3 is: -CH 2 -CH 2 OH,

[0056] The preparation steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0058] An organosilicon composite multifunctional textile finishing agent, the structural formula is as follows:

[0059]

[0060] In the formula: n=100; a=14; b=18; R1 is: R2 is: -CH 3 R3 is: -CH 2 OH,

[0061] The preparation steps are the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com