Energy-conserving process for washing and dedusting by methyl monomer synthesis gas

A technology for washing dust and synthesizing gas, which is applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., to achieve the effects of reducing energy consumption, saving cooling consumption, saving heat and cooling consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

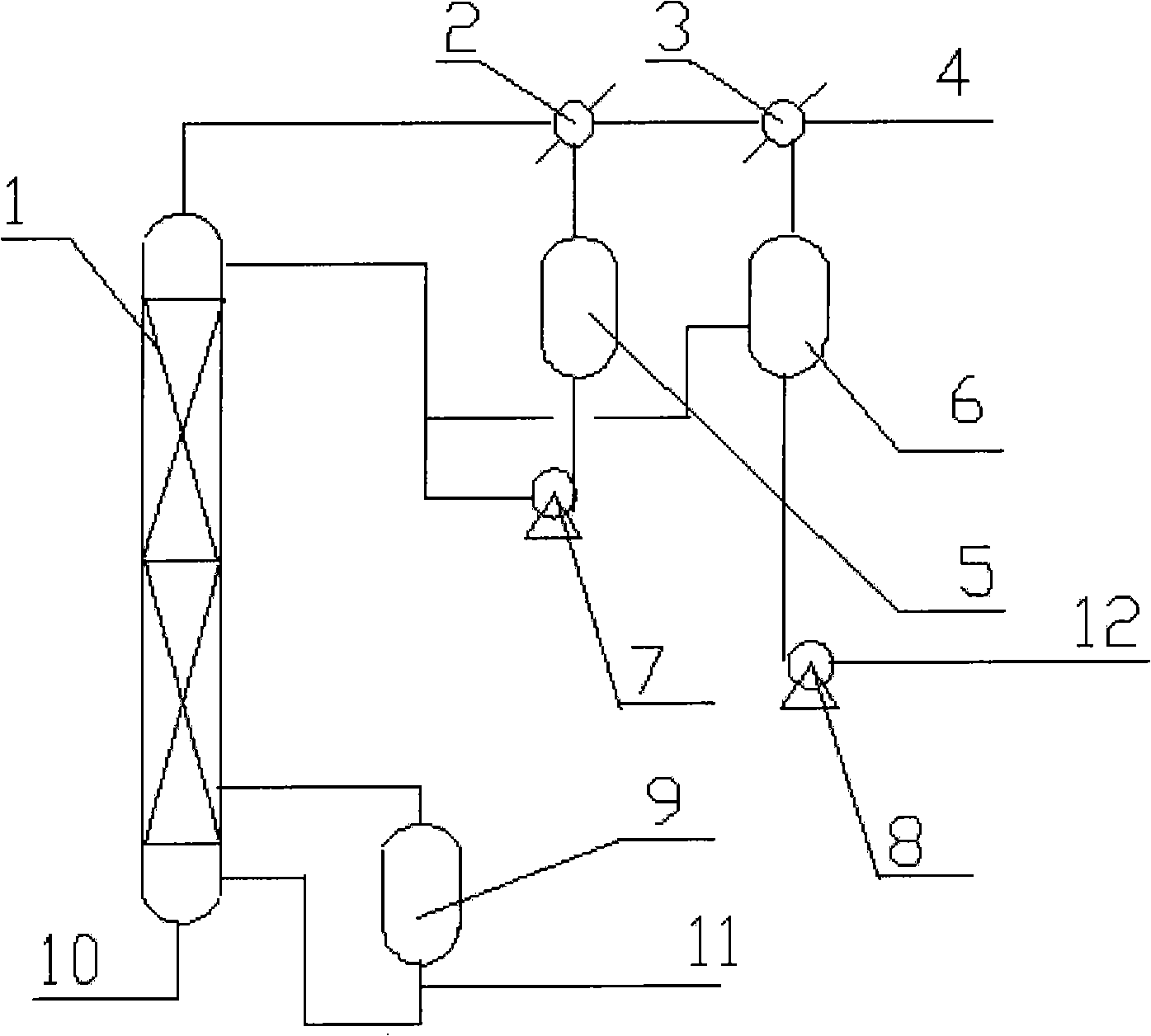

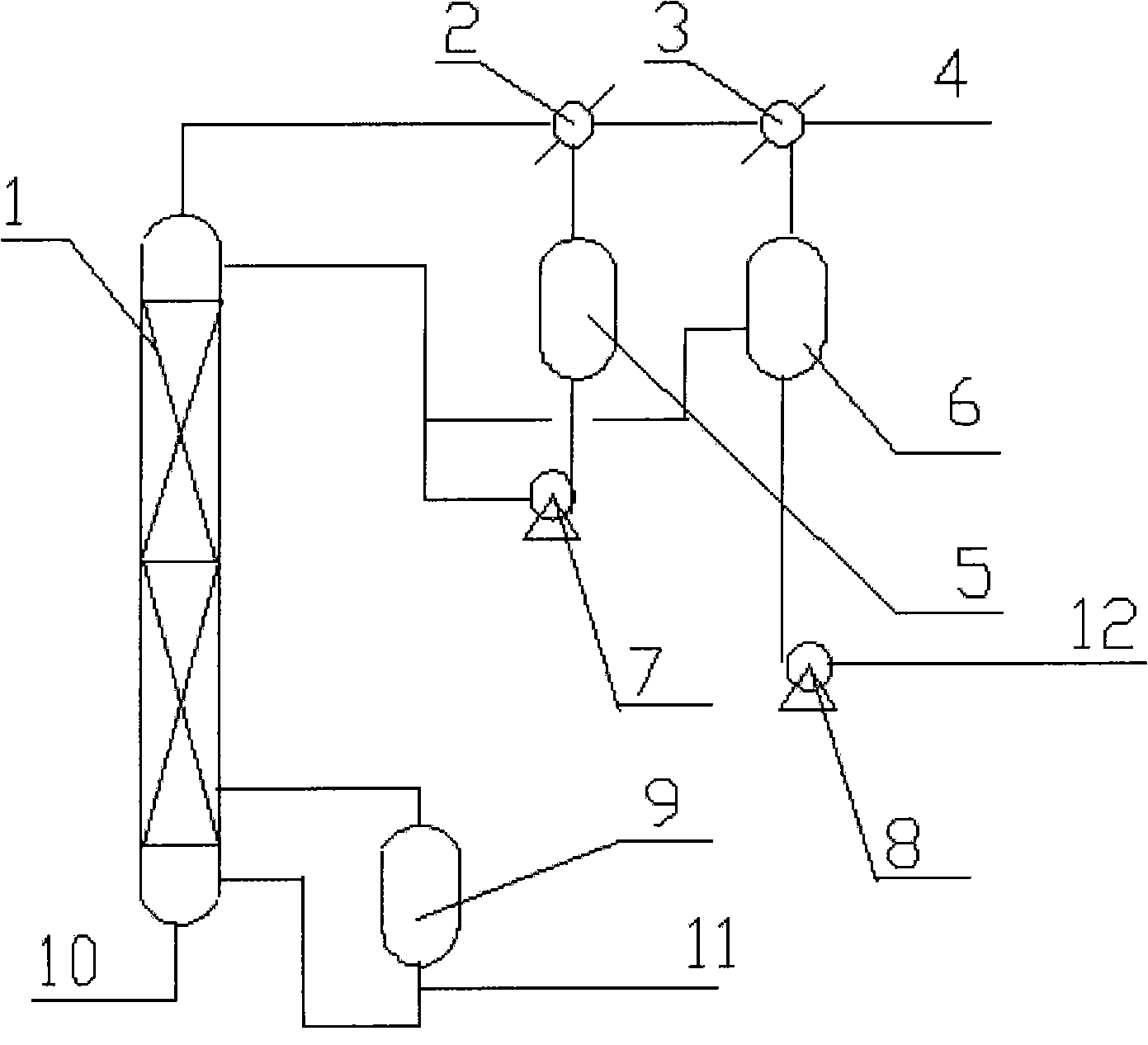

[0029] The high-temperature organochlorosilane synthesis gas from the fluidized bed reactor for chlorosilane synthesis enters the scrubber 1 from the organochlorosilane synthesis gas inlet 10 below the scrubber after passing through primary and secondary cyclone separators for preliminary dust removal. In the washing tower, the high-temperature organic chlorosilane synthesis gas containing dust and the condensed reflux liquid with a relatively high boiling point are further dedusted through reverse contact to achieve the purpose of dedusting and purification.

[0030] The purified organic chlorosilane synthesis gas obtained from the top of the washing tower 1 enters a condenser 2, and the temperature of the tower top gas after washing and dust removal is about 82.2°C. The first condenser at the top of the washing tower uses 20-40°C circulating water as a cooling medium for cooling and condensation. The temperature of the condensate is controlled at 35-45°C.

[0031] The conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com