Biodegradation process for ultra-thick oil waste water in oilfield

A technology for biodegradation and ultra-heavy oil, applied in the direction of separation methods, grease/oily substances/suspton removal devices, chemical instruments and methods, etc. Conditions are difficult to control and other problems, to achieve the effect of reducing the generation of oily sludge, ideal treatment effect, and efficient degradation of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

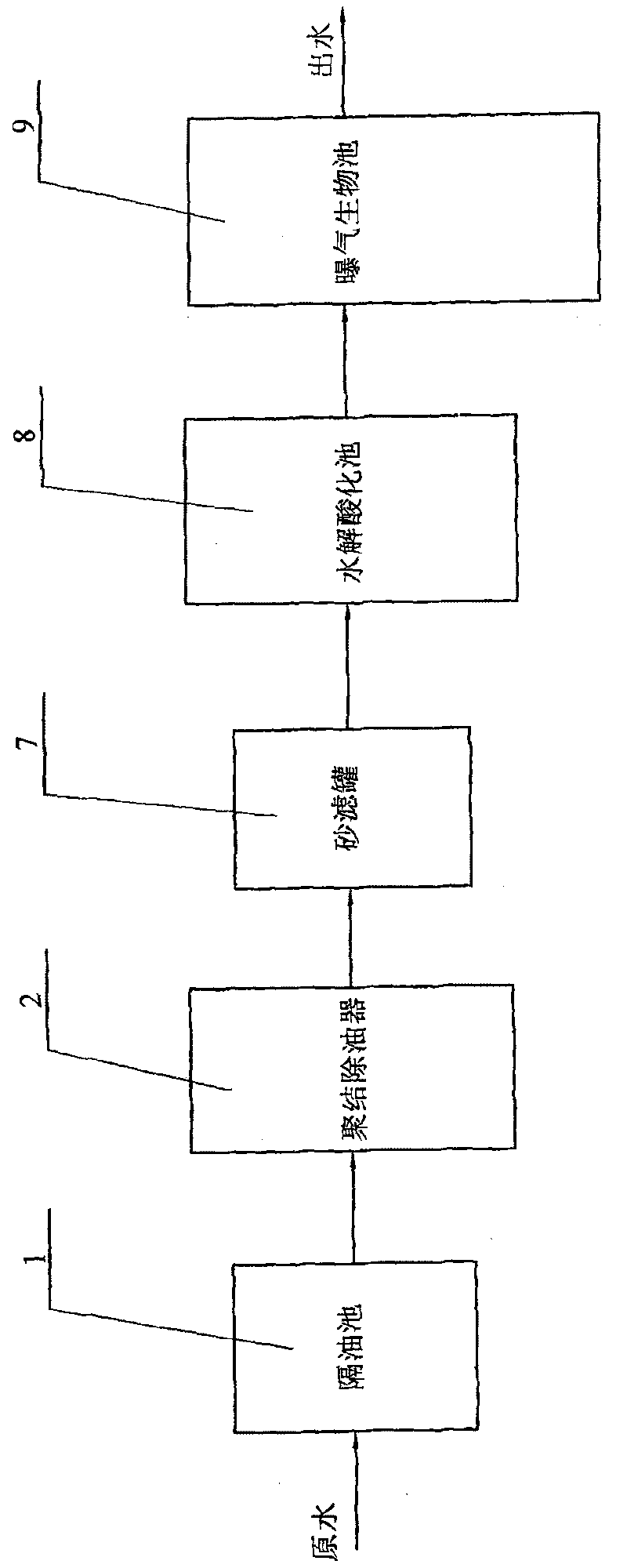

[0009] Specific implementation mode one: combine Figure 1 ~ Figure 4 with Figure 7 The biodegradation method of oilfield super-heavy oil wastewater of the present invention is completed by the following steps: A, oil separation treatment: raw water flows into the pond from one end of the oil separation pond 1, flows out from the other end, and the oil droplets with a specific gravity less than 1.0 float on the water surface, and the specific gravity The impurities greater than 1.0 sink to the bottom of the pool, and the oil droplets floating on the water surface are collected through the oil collection pipe; B. Coalescing and degreasing: the raw water after the oil separation treatment enters the mesh packing in the coalescing degreasing device 2 to gather Junction unit 3, slow flow chamber 4 and degreasing unit 5 carry out degreasing treatment, after that, raw water flows out of coalescing degreaser 2 through water outlet chamber 6 in coalescing degreasing device 2; C, sand...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 7 Describe this embodiment, in step E of this embodiment: the particle size of the natural ceramsite filler 12 in the anaerobic zone 10 is 3-5mm, and the true density is 1.55g / cm 3 , the porosity is 40-45%; the particle size of the natural ceramsite filler 13 in the aerobic zone 11 is 2-4mm, and the true density is 1.58g / cm 3 , The porosity is 38-42%. The steps of other degradation methods are the same as those in Embodiment 1.

specific Embodiment approach 3

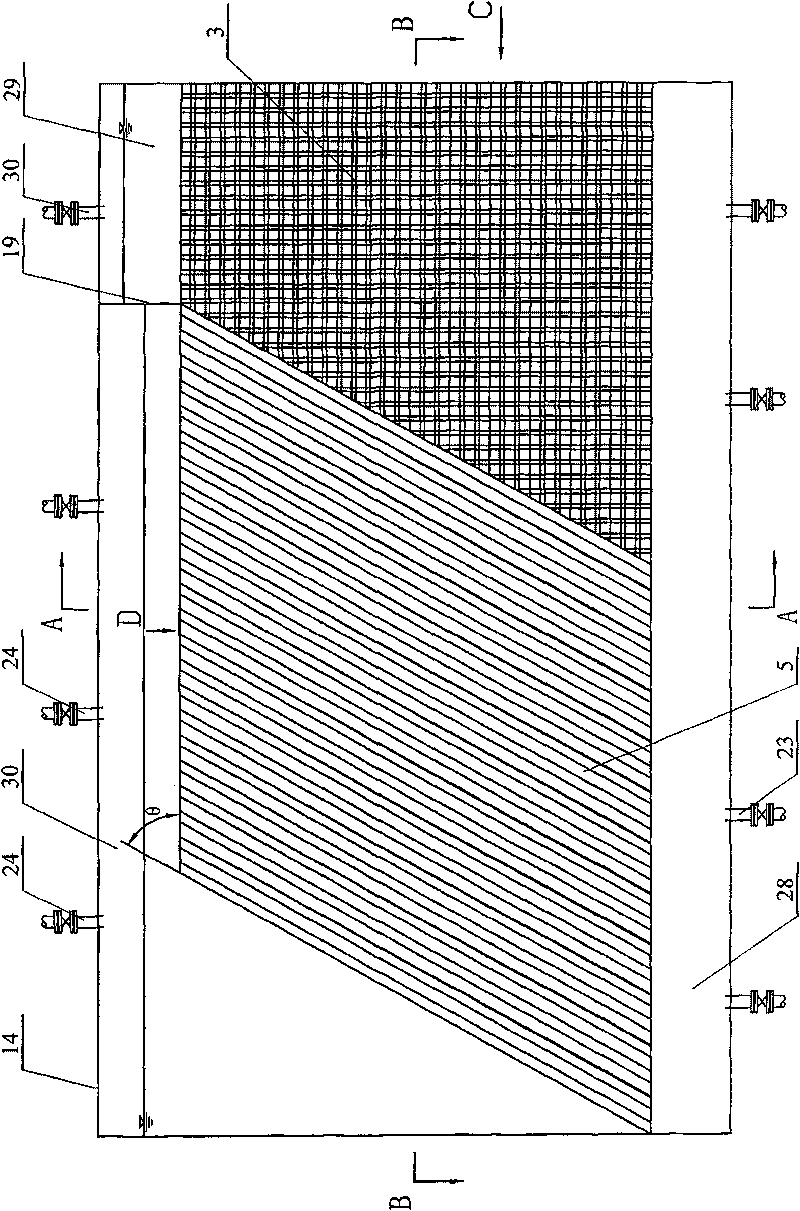

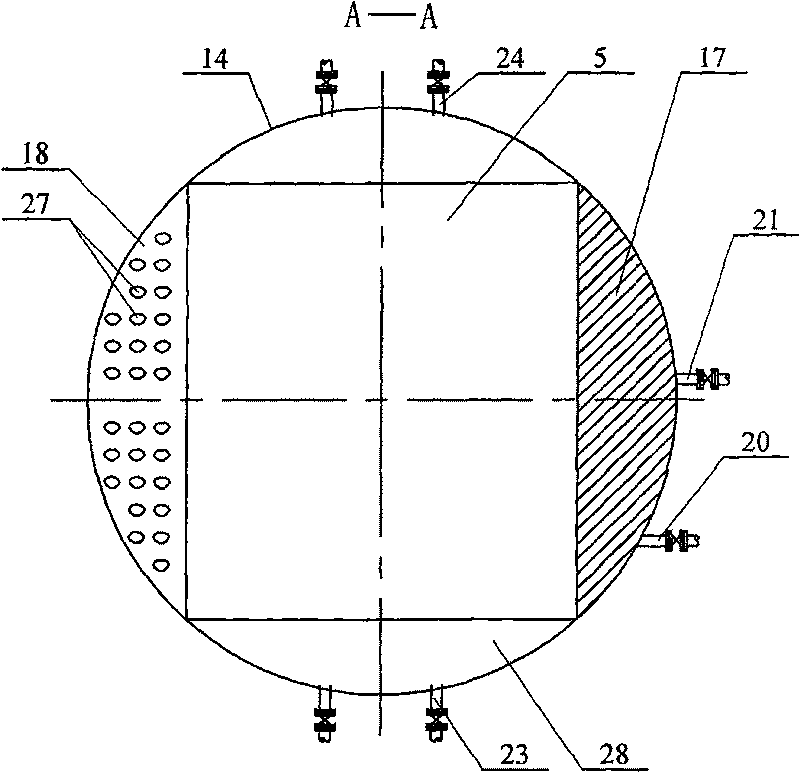

[0011] Specific implementation mode three: combination Figure 2 ~ Figure 4Describe this embodiment, in this embodiment in step B: the coalescing degreaser 2 is composed of a sealed tank body 14, a mesh filler coalescing unit 3, an oil removal unit 5, a first partition 17, a second partition 18. The third partition 19, a plurality of water inlet pipes 20, a plurality of water outlet pipes 21, a plurality of mud discharge pipes 23 and a plurality of oil discharge and exhaust pipes 24; the sealed tank body 14 is arranged horizontally, and the The mesh packing coalescing unit 3 and the degreasing unit 5 are arranged inside the sealed tank 14 along the axial direction, and the first partition plate 17 is obliquely fixed on the mesh packing coalescing unit 3 and the oil removing unit 5 Between the end faces on one side, the cavity surrounded by the mesh packing coalescence unit 3, the degreasing unit 5 and the sealed tank body 14 is divided into a water inlet chamber 25 and a water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com