Biodegradable high molecular nanometer particles, specialty polymer thereof and preparation method thereof

A polymer and block polymer technology, applied in the field of biodegradable polymer nanoparticles, can solve the problems of biosafety and biocompatibility hazards, impossible to achieve a constant rate of drug release, etc., to avoid biosafety And the hidden danger of biocompatibility, the effect of excellent biodegradability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

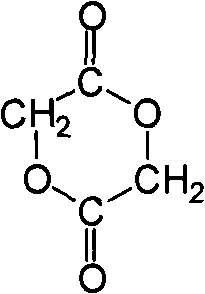

[0039] According to the reaction mass ratio shown in table 1, glycolide, L-lactide, polyethylene glycol (PEG), and the catalyzer (titanium that is the sum of glycolide and L-lactide weight 0.01~0.15%) butyl ester or stannous isooctanoate), mixed uniformly in a polymerization tube, and then reacted at a temperature of 130-180°C for 10-70 hours under 15Pa vacuum conditions to obtain a series of products with different lengths and ratios of hydrophilic / hydrophobic segments. Polymers PLGE-1 to PLGE-12.

[0040] Table 1 Preparation of PLGE polymer

[0041]

[0042] The molecular weight distribution of the above-mentioned PLGE polymer is between 1.5-2.5.

Embodiment 13~24

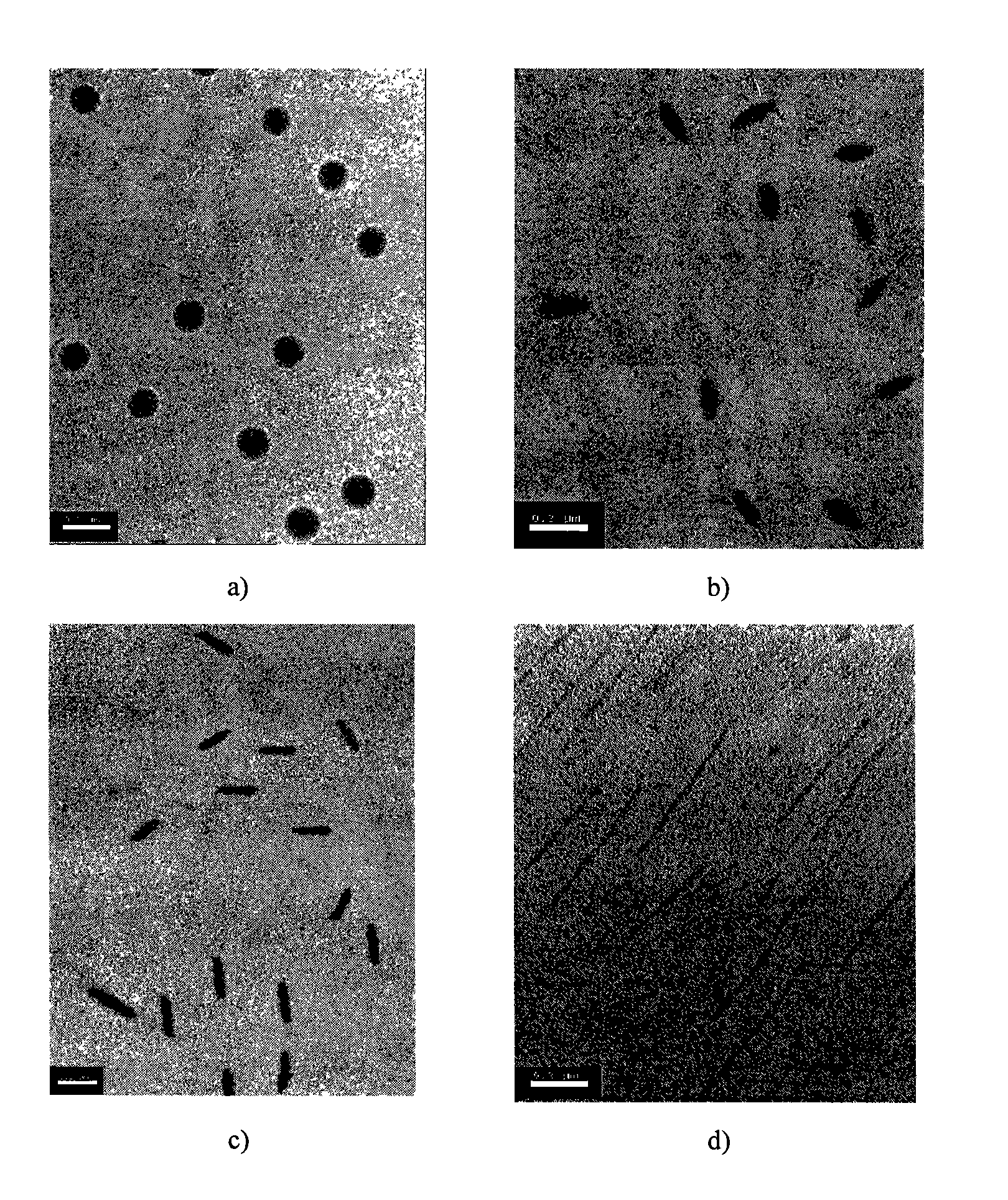

[0044] PLGE is an amphiphilic block copolymer containing both a hydrophilic segment (PEG) and a hydrophobic segment (PLGA) in the polymer molecule, so PLGE nanoparticles can adopt the unique self-expression of amphiphilic block copolymer molecules. Prepared by emulsification-solvent diffusion self-assembly method. The specific preparation method is as follows: First, dissolve the PLGE polymer in a water-soluble organic solvent to form a PLGE organic phase, and then gradually add the PLGE organic phase to a certain temperature of the water phase at 20-30 ° C, so that the organic solvent naturally diffuses into the water phase , while the hydrophilic PEG segment in the PLGE molecule migrates to the interface and enriches, and finally solidifies to form PLGE nanoparticles with a core-shell structure with the hydrophobic PLGA segment as the core and the hydrophilic PEG segment as the shell. , the particle size range of the nanoparticles is 10-200nm. The water-soluble organic solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com