Process for extracting phospholipid rich-containing eicosapentaenoic acid and docosahexenoic acid

A technology of docosahexaenoic acid and eicosapentaenoic acid, which is applied in the direction of edible phospholipid compositions, medical preparations containing active ingredients, and pharmaceutical formulas. Growth and development, high development and utilization value, and the effect of enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

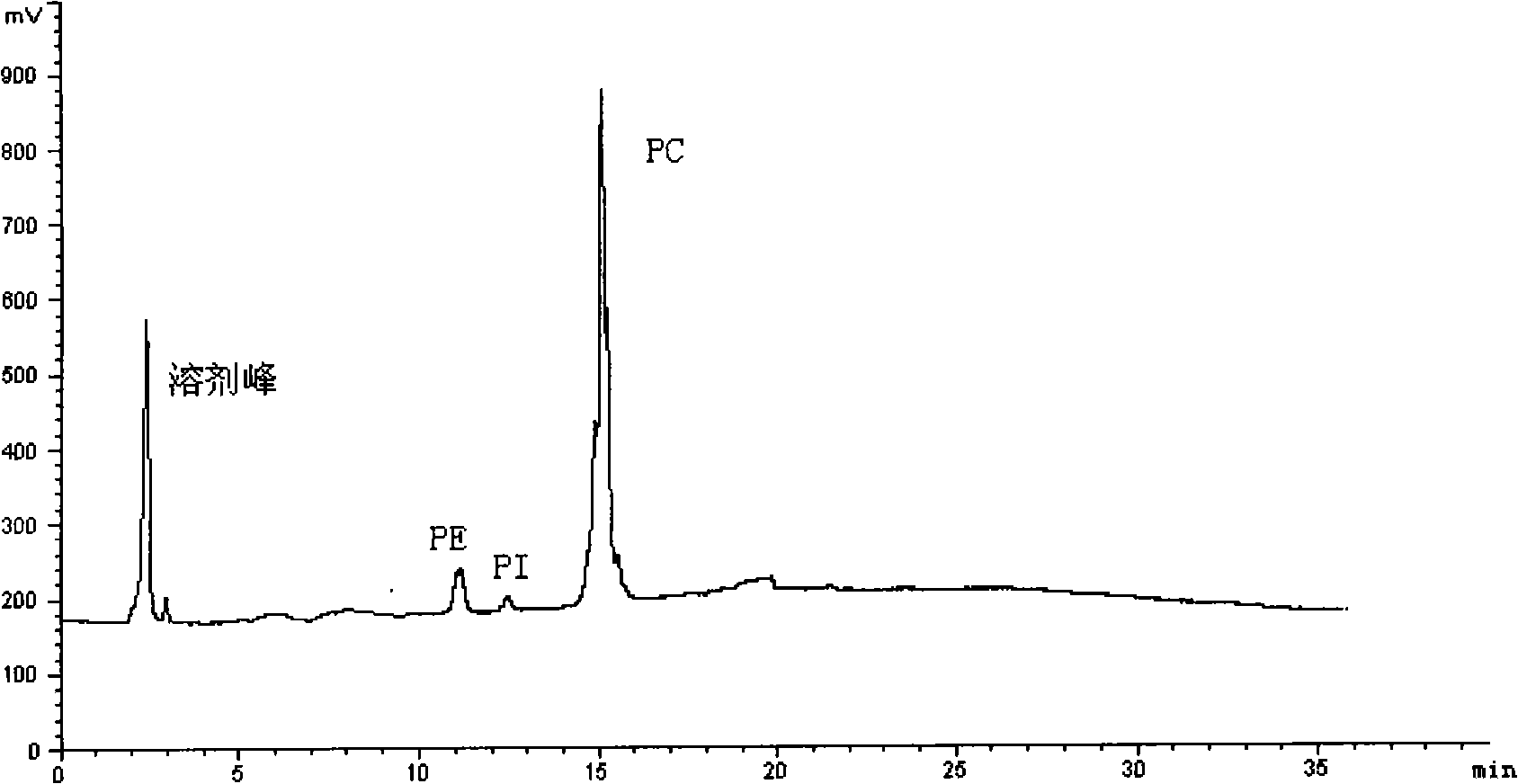

[0018] Get tap water and clean cod roe, remove impurity, after adding the water of 4 times of weight, make homogenate with colloid mill, gained homogenate is through 12h vacuum freeze-drying, after pulverizing with pulverizer, obtain water content and be 4.0% (weight percent , the same below), get 100g of the cod roe powder and put it into the extraction kettle of a supercritical carbon dioxide extraction device, remove neutral fat and cholesterol in the egg powder through supercritical carbon dioxide extraction and secondary separation, and the pressure in the extraction kettle is 30MPa, the temperature is 60°C; the first-stage separation pressure is 8MPa, the separation temperature is 45°C; the second-stage separation pressure is 6MPa, the separation temperature is 35°C, the flow rate of carbon dioxide is 50ml / g, and the extraction time is 6h. Take out the cod roe powder that has removed the neutral fat and cholesterol from the kettle, add 15 times the weight of 90% ethanol a...

Embodiment 2

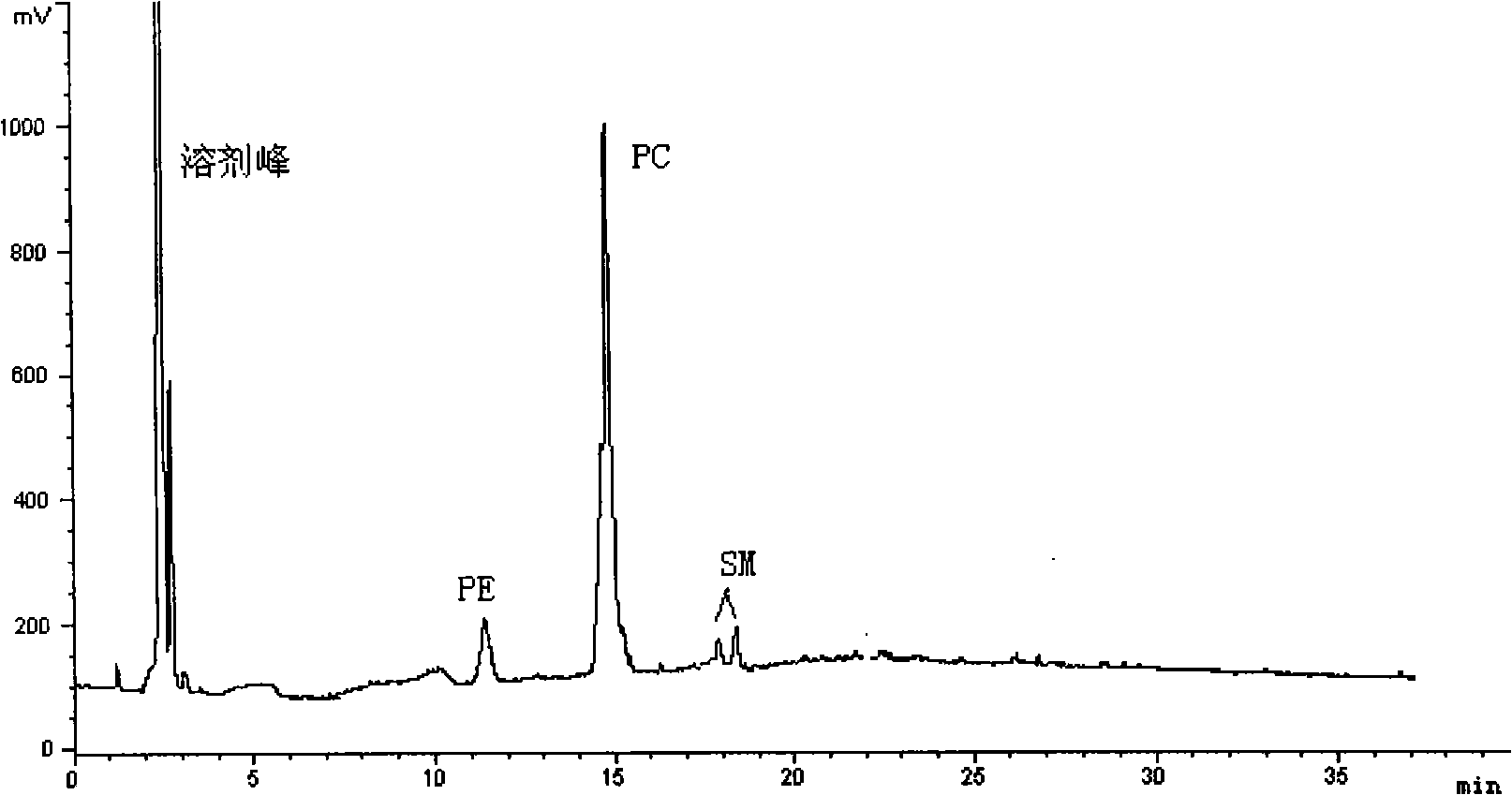

[0020] Get tap water to clean the squid roe, remove impurities, add 6 times the weight of water, and use a colloid mill to make a homogenate. The resulting homogenate is vacuum freeze-dried for 24 hours and pulverized with a pulverizer to obtain squid roe with a water content of 5.0%. powder, get 200g of it and put it into the extraction kettle of a supercritical carbon dioxide extraction device, remove the neutral fat and cholesterol in the egg powder through supercritical carbon dioxide extraction and secondary separation, the pressure in the extraction kettle is 30MPa, and the temperature is 45°C; The separation pressure of the first stage is 13MPa, the separation temperature is 45°C; the separation pressure of the second stage is 8MPa, the separation temperature is 40°C, the flow rate of carbon dioxide is 100ml / g, the extraction time is 8h, and the neutralization is removed from the extraction kettle The squid roe powder of fat and cholesterol, add the 95% ethanol aqueous s...

Embodiment 3

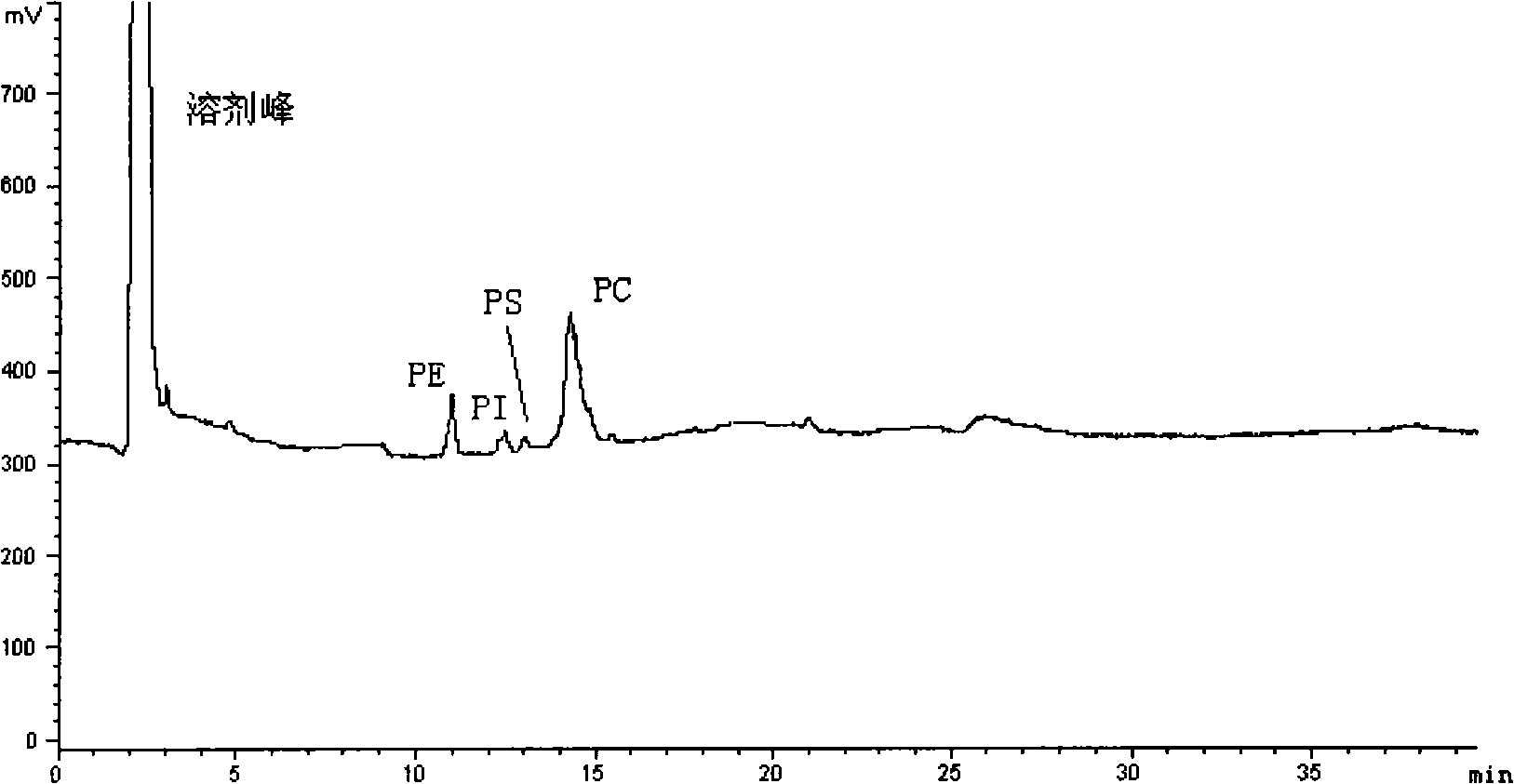

[0022] Take tap water to wash the sea urchin gonads, remove impurities, add 5 times the weight of water, and use a colloid mill to make a homogenate. The obtained homogenate is vacuum freeze-dried for 16 hours and crushed with a pulverizer to obtain sea urchin gonads with a water content of 4.5%. Take 250g of it and put it into the extraction kettle of the supercritical carbon dioxide extraction device, remove the neutral fat and cholesterol in the sea urchin gonad powder through supercritical carbon dioxide extraction and secondary separation, the pressure in the extraction kettle is 25MPa, and the temperature is 55°C ;The separation pressure of the first stage is 13.5MPa, the separation temperature is 50°C; the separation pressure of the second stage is 9MPa, the separation temperature is 45°C, the flow rate of carbon dioxide is 150ml / g, the extraction time is 10h, take it out from the extraction kettle The sea urchin gonad powder of neutral fat and cholesterol is extracted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com