Metal cream composing substance for capacitor

A metal paste, capacitor technology, applied in the direction of fixed capacitor electrodes, metal/alloy conductors, components of fixed capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

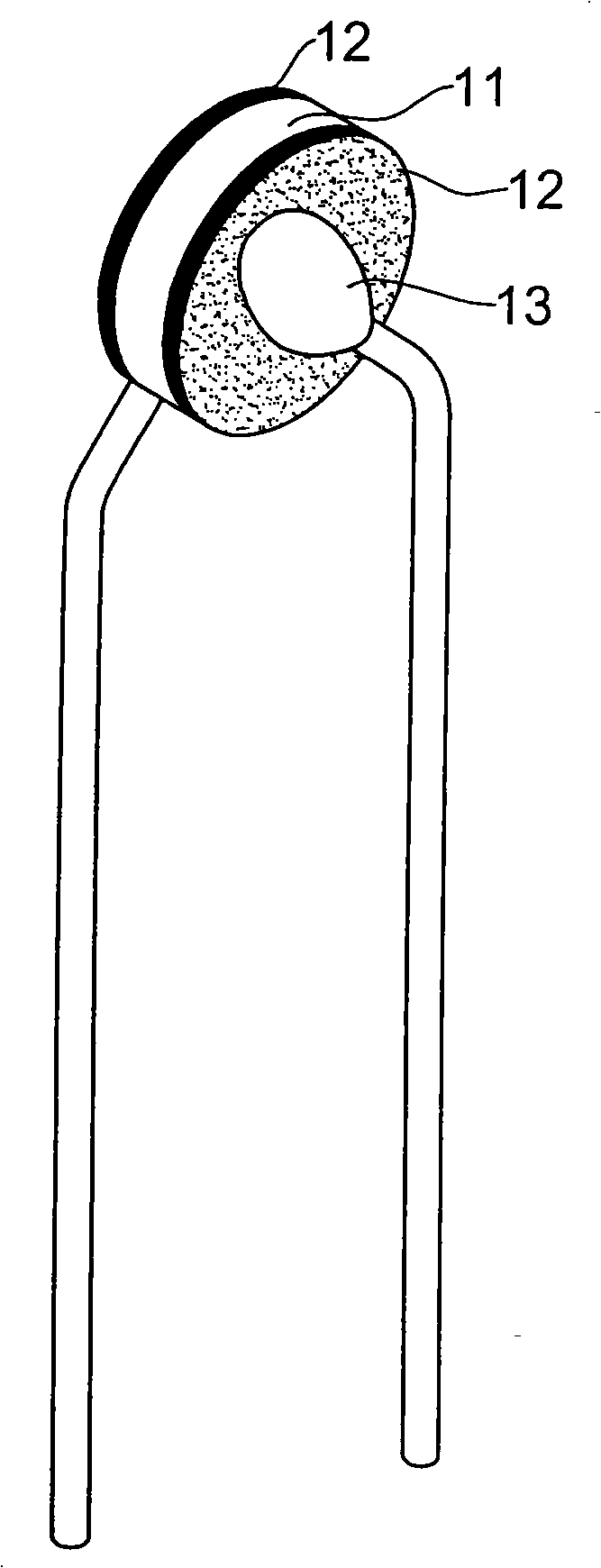

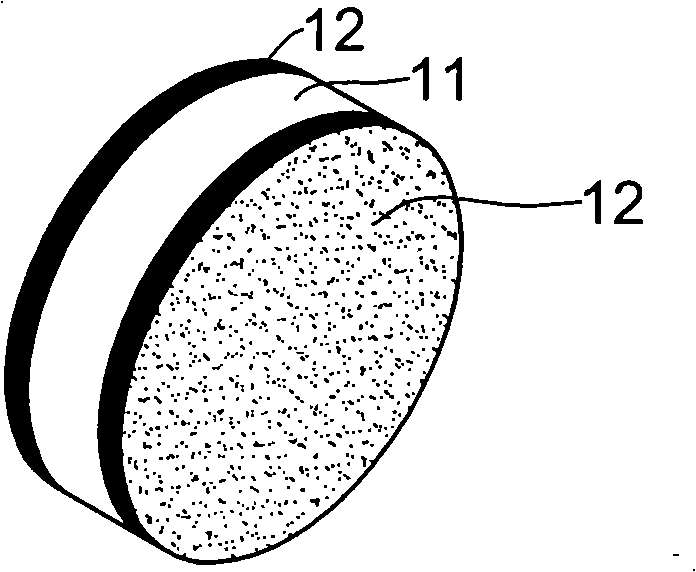

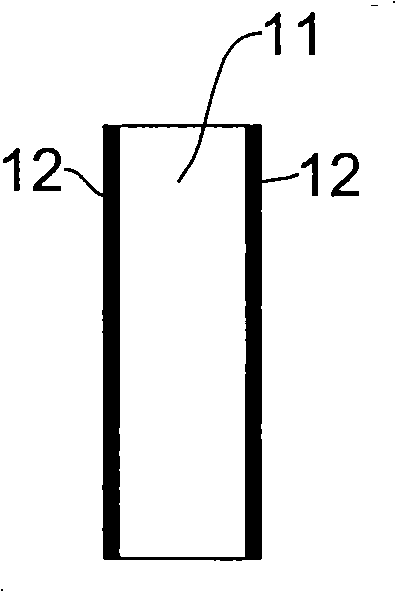

[0021] see Figure 1 to Figure 3 , are respectively a three-dimensional schematic diagram, a partially exploded three-dimensional schematic diagram and a side view of a capacitor.

[0022] The first embodiment of the present invention is a capacitor metal paste composition, which is used to make a terminal electrode of a capacitor. The capacitor includes a disk-shaped dielectric 11, the medium 11 has two planes, a disk-shaped terminal electrode 12 is formed on the two planes, and a pin 13 is combined on the outer surface of each terminal electrode 12 for The capacitor is provided on a substrate (not shown in the figure).

[0023] The capacitor metal paste composition of the present embodiment is formed as the terminal electrode 12 of the aforementioned capacitor, which includes:

[0024] A metal powder, which is copper powder or a powder comprising copper and its alloy; in this embodiment, copper powder is used as the metal powder;

[0025] A glass powder, which has the fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com