Manufacturing method and apparatus of anisotropic functional member

A technology of functional components and manufacturing methods, applied in the field of rapid prototyping, can solve the problems of slow drying, easy collapse, and poor service performance of materials, and achieve the effects of uniform strength of workpieces, easy blockage, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

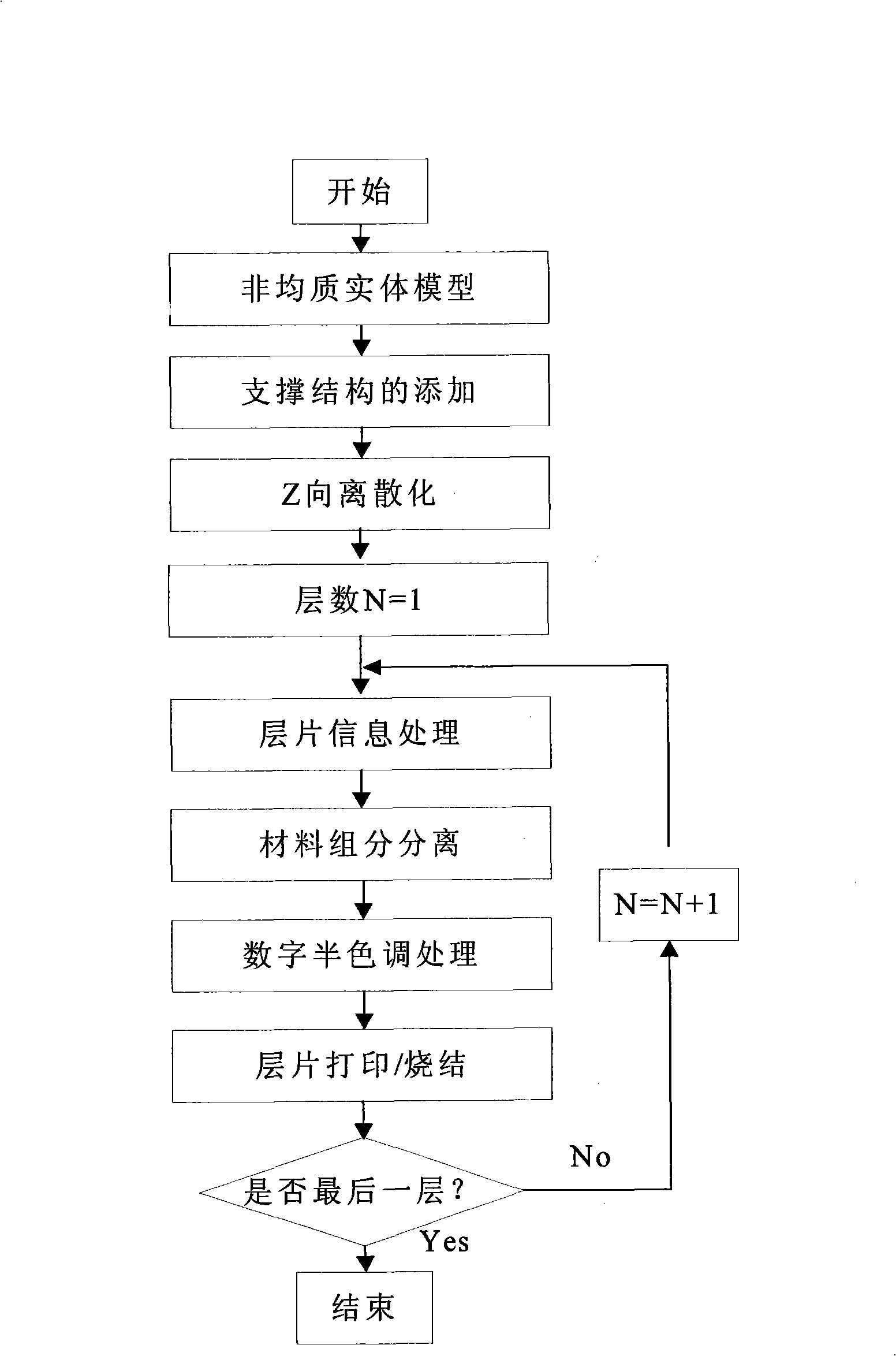

Method used

Image

Examples

Embodiment 1

[0061] A three-dimensional heterogeneous functional component of zirconia toughened alumina is manufactured by using the manufacturing method and device described in the present invention. The process is as follows:

[0062] 1. Configure printing ink

[0063] According to the requirements of the component, configure two inks, one is designed as aluminum nitrate aqueous solution, the concentration is 15vol%; the other is designed as zirconium sulfate aqueous solution, the concentration is 20vol%.

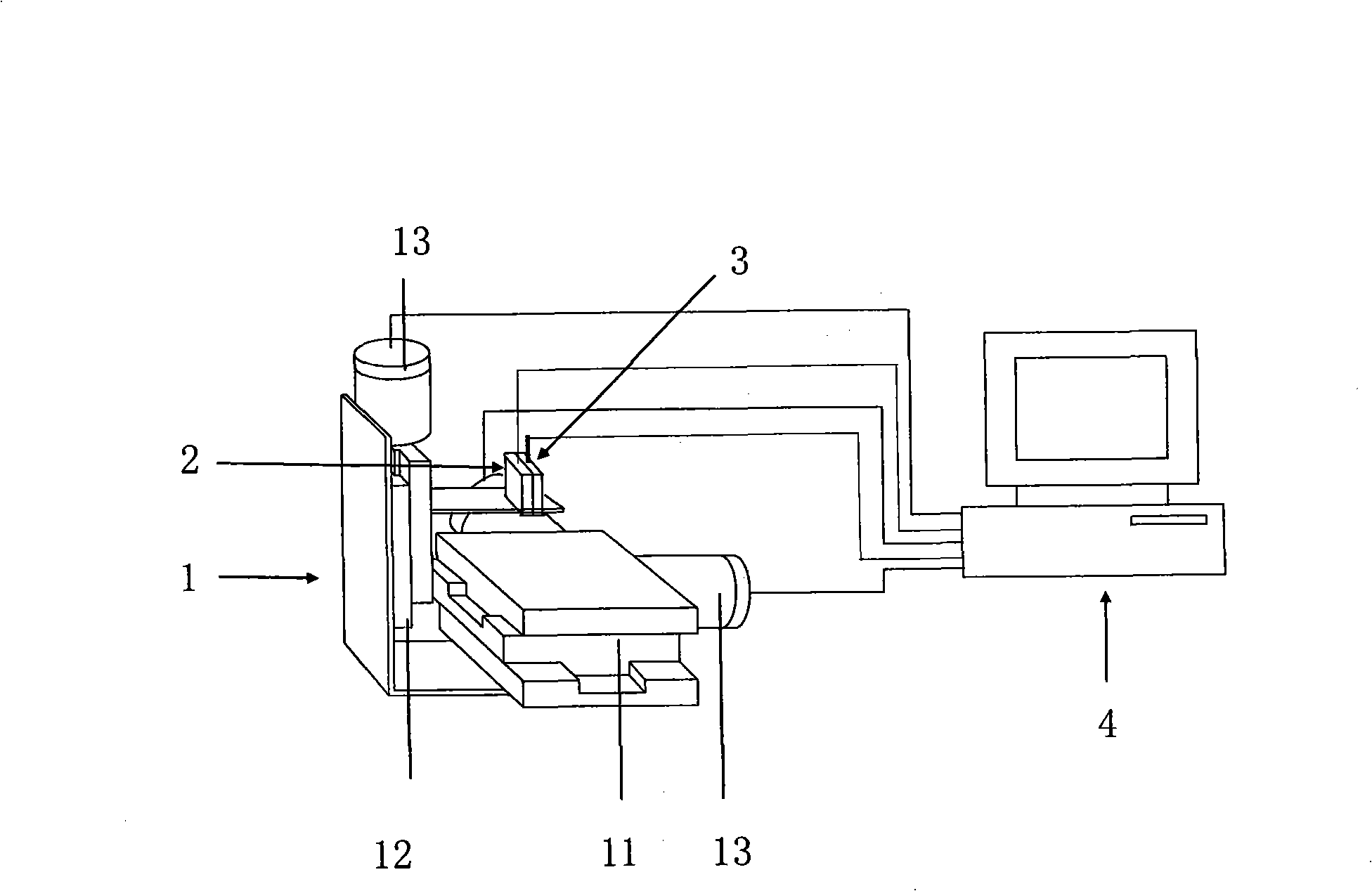

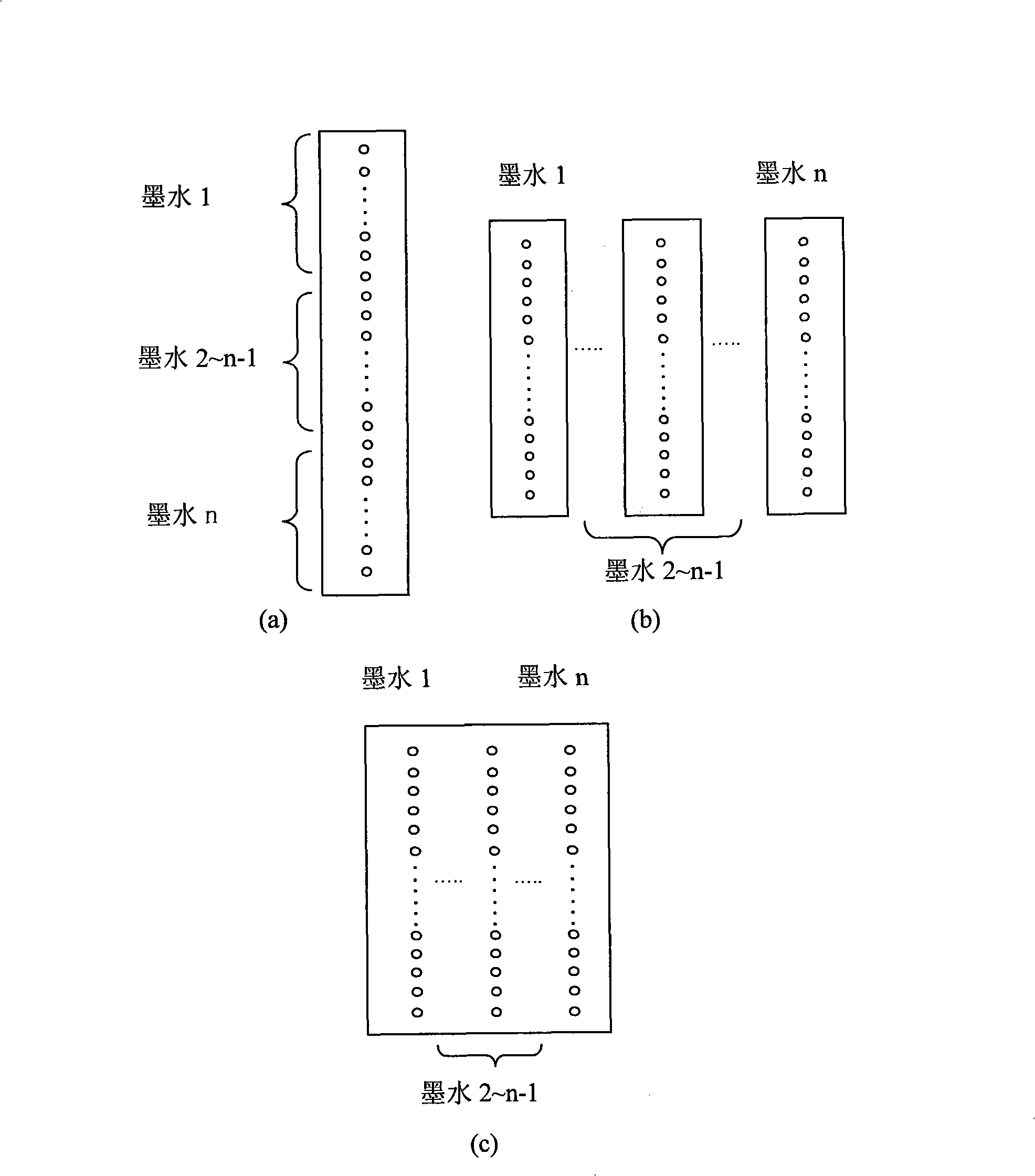

[0064] 2. Set up follow-up laser scanning

[0065] Two sets of InGaAsP / InP semiconductor lasers with a power of 0.1-1W and 0.1-5W are used to couple with an optical fiber with an inner diameter of 120μm to form a laser head. The distribution of the laser beam is designed as a single head and a single row (see Figure 4 (a)); the distribution of nozzle holes in the print head is also designed as a single head and single row (see image 3 (a)); the printing nozzle and the laser head...

Embodiment 2

[0070] A three-dimensional heterogeneous functional component of cerium oxide toughened alumina is manufactured by using the manufacturing method and device described in the present invention. The process is as follows:

[0071] 1. Configure printing ink

[0072] According to the requirements of the components, two printing inks are configured, one is designed as an aluminum chloride aqueous solution with a concentration of 19vol%; the other is designed as a cerium nitrate ethanol solution with a concentration of 17vol%.

[0073] 2. Set up follow-up laser scanning

[0074] Two groups of CO with power of 0.1-3W and 0.1-10W are used 2 The laser is coupled with an optical fiber with an inner diameter of 50 μm to form a laser head, and the distribution of the laser beam is designed to be multi-headed and multi-column (see Figure 4 (b)); the distribution of nozzle holes in the print head is also designed to be multi-head and multi-column (see image 3 (b)); the print nozzle an...

Embodiment 3

[0079] A three-dimensional heterogeneous functional component of alumina toughened together by zirconia and ceria is manufactured by using the manufacturing method and device described in the present invention. The process is as follows:

[0080] 1. Configure printing ink

[0081] According to the requirements of the components, configure three printing inks, one is designed as aluminum chloride aqueous solution, the concentration is 19vol%; the second is designed as cerium acetate aqueous solution, the concentration is 17vol%; the third is designed as zirconium sulfate aqueous solution, the concentration is 16vol% %.

[0082] 2. Set up follow-up laser scanning

[0083] Three groups of Nd:YAG lasers with a power of 0.1-2W, 0.1-3W and 0.1-10W are used to couple with an optical fiber with an inner diameter of 80 μm to form a laser head. The distribution of the laser beams is designed as multiple heads and multiple rows (see Figure 4 (b)); the distribution of nozzle holes in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com