Building energy-saving inner partition composite board

A technology for building energy saving and internal partition walls, applied in construction, building structure, covering/lining, etc., can solve the problems of complex structure, high cost, heavy weight, etc., and achieve good sound insulation effect, low cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

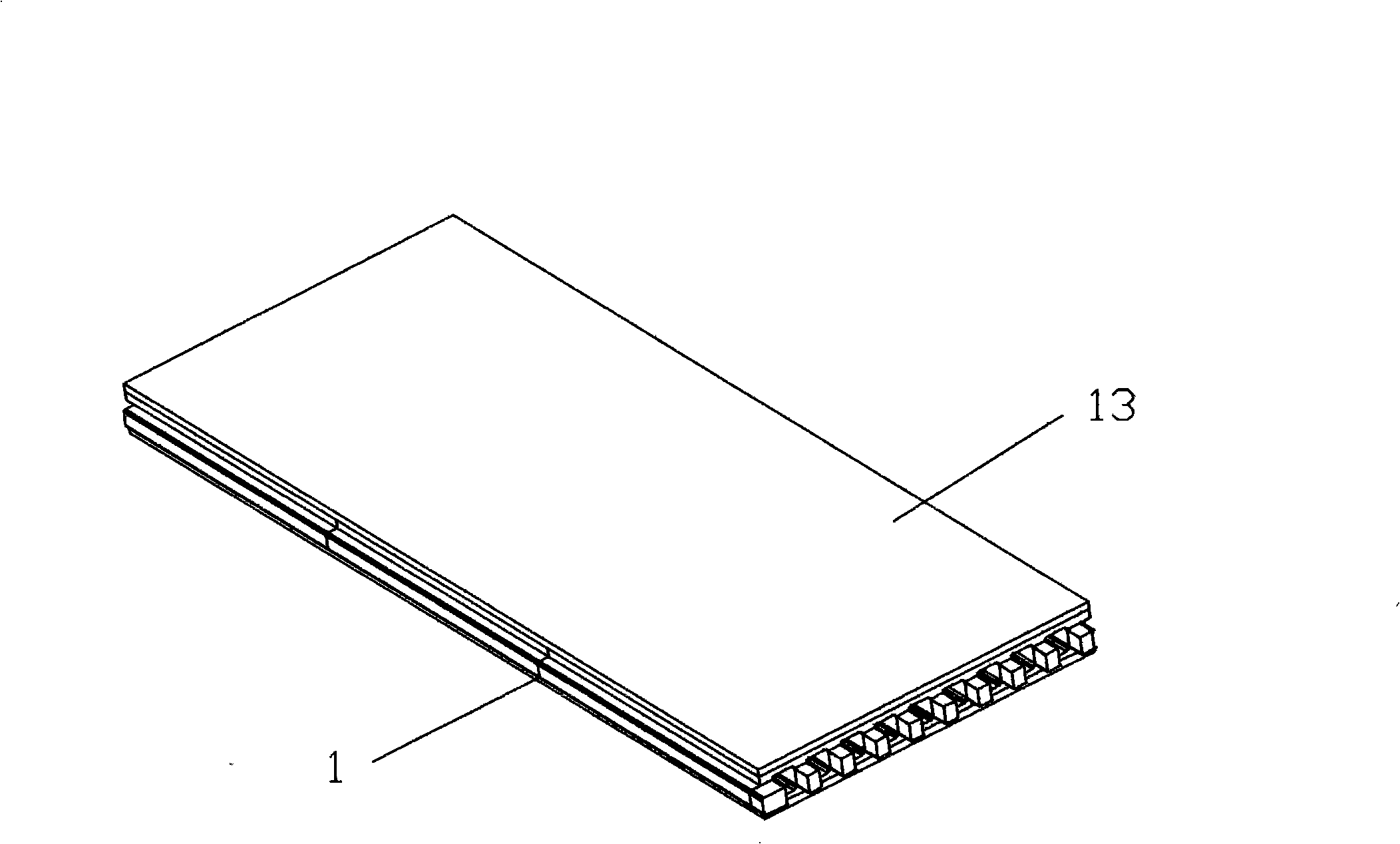

[0022] EPS round and square porous thermal insulation modules, composite partition wall panels include sandwich panels 1 and 2 made of molded thermal insulation materials. structure. The sides corresponding to the left and the right are provided with upper convex ribs 5 and lower grooves 6 that cooperate with each other to form an overlapping groove-and-groove structure. A dovetail groove 7 and a smooth plane 8 are arranged on the outer surface of the straight plate. There are square through holes 9, round through holes 10 and equally distributed square hole ribs 11 and round hole ribs 12 in the middle of the straight plate shape. The upper and lower surfaces of the composite partition board are asbestos cement boards, fiber calcium silicate boards, aluminum-plastic boards or straw boards 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com