Design and construction method of deep foundation ditch

A construction method and deep foundation pit technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve problems such as complex design and construction of foundation pit support, damage to the natural groundwater balance, and damage to trees, so as to shorten the construction period and prevent Settling and waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

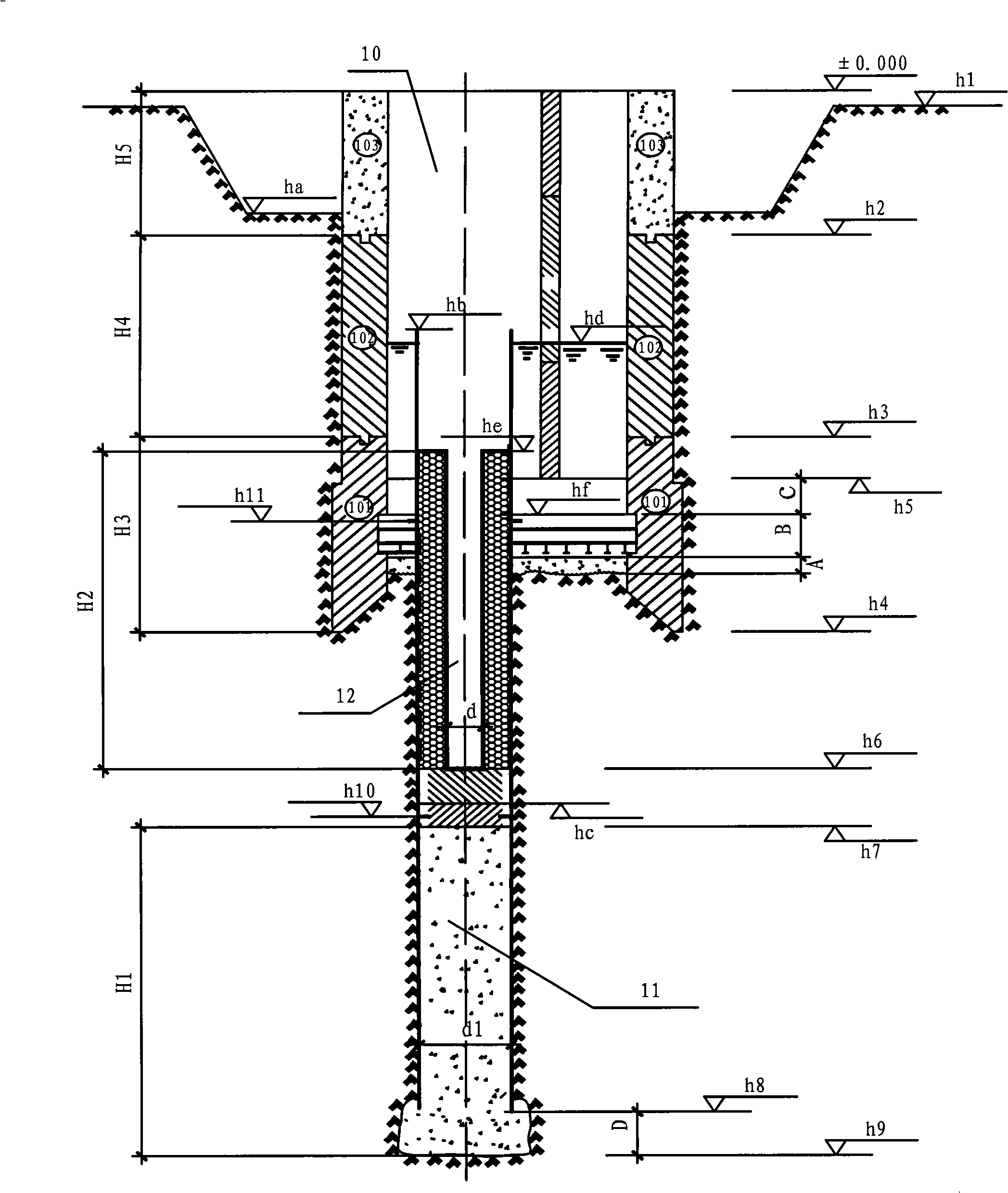

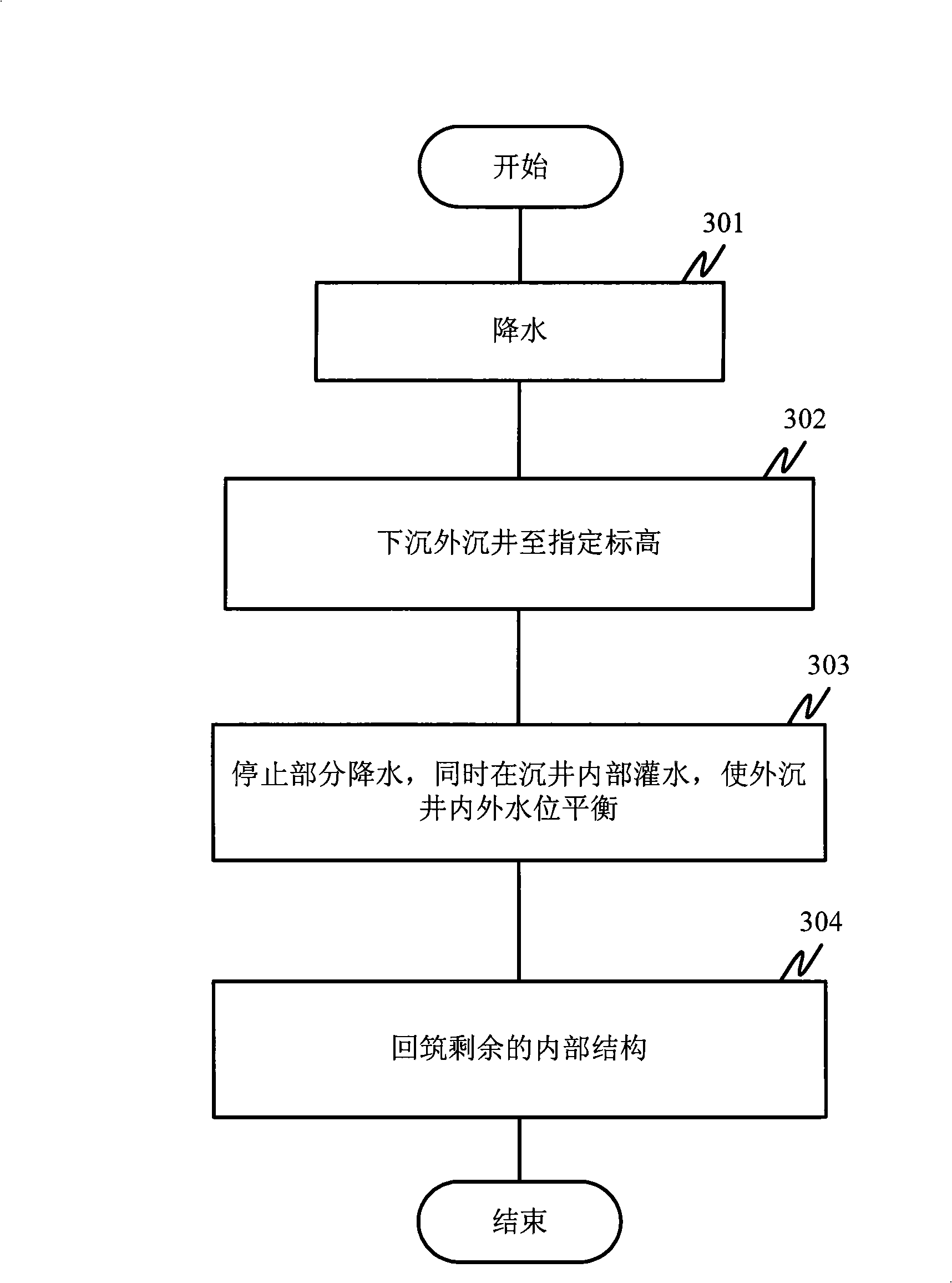

[0039] The main idea of the present invention is to dewater and sink the caisson first, stop part of the dewatering after sinking the caisson to a specified elevation, and at the same time fill the inside of the caisson with water to balance the water level inside and outside the caisson. Afterwards, the rest of the internal structure of the caisson was built, including underwater mechanical drilling, lowering of steel casings, and underwater pouring of concrete deep foundations in the steel casings. In the process of returning to the construction, the follow-up work is completed through reciprocating water pumping and refilling water at work intervals. In this way, the precipitation is not continuous during the whole construction process, and the precipitation is greatly reduced, so the present invention can achieve the effect of saving water resources.

[0040] The key to the implementation of the present invention is that the underwater mechanical hole is drilled into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com