Inorganic polymer material for sealing heavy metal castoff

An inorganic polymer and waste technology, applied in solid waste management, sustainable waste treatment, cement production, etc., can solve the problems of difficulty in commercialization of inorganic silicon-aluminum polymer solid sealing materials, low strength, and decreased solid sealing efficiency. , to achieve the effect of excellent heavy metal solid sealing performance, broad application prospects and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

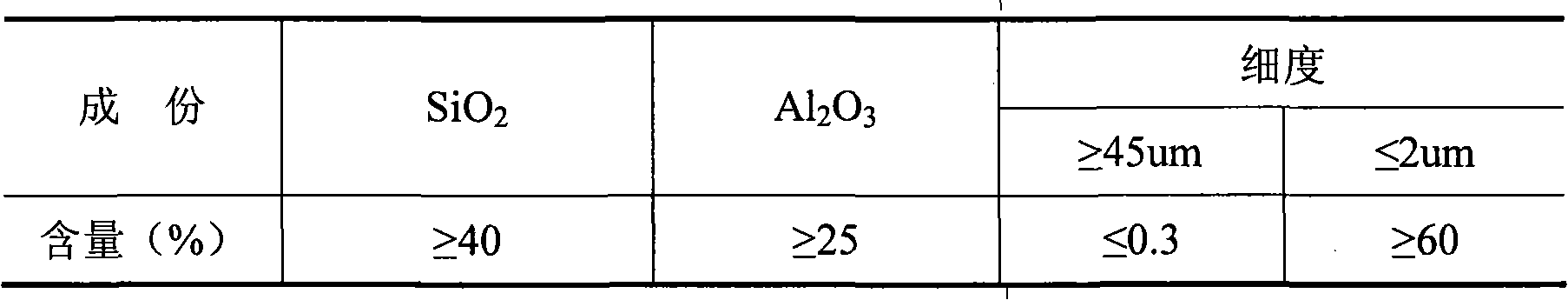

Method used

Image

Examples

Embodiment 1

[0028] Metakaolin 35.1%

[0029] Fly Ash 0.4%

[0030] Slag 3.94%

[0031] Basic activator 10.6%

[0032] Sand 50.0%

[0033] The above components were prepared according to the aforementioned process to obtain an inorganic silicon-aluminum polymer sealing material, and its properties were measured as follows:

[0034] The compressive strength (28 days) is 32.9MPa, the flexural strength (28 days) is 6.71MPa, the encapsulation efficiency of Cu ions is 95.6%, and the encapsulation efficiency of Pb ions is 96.5%.

Embodiment 2

[0036] Metakaolin 27.3%

[0037] Fly ash 0.3%

[0038] Slag 11.82%

[0039] Basic activator 10.6%

[0040] Sand 50.0%

[0041] The above components were prepared according to the aforementioned process to obtain an inorganic silicon-aluminum polymer sealing material, and its properties were measured as follows:

[0042] The compressive strength (28 days) is 53.7MPa, the flexural strength (28 days) is 7.02MPa, the encapsulation efficiency of Cu ions is 97.1%, and the encapsulation efficiency of Pb ions is 97.5%.

Embodiment 3

[0044] Metakaolin 19.5%

[0045] Fly Ash 0.2%

[0046] Slag 19.7%

[0047] Basic activator 10.6%

[0048] Sand 50.0%

[0049] The above components were prepared according to the aforementioned process to obtain an inorganic silicon-aluminum polymer sealing material, and its properties were measured as follows:

[0050] The compressive strength (28 days) is 64.1MPa, the flexural strength (28 days) is 8.01MPa, the encapsulation efficiency of Cu ions is 98.3%, and the encapsulation efficiency of Pb ions is 98.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com