Rarefaction air condensing trapping device with liquid nitrogen suction refrigeration

A technology of liquefied air and liquid nitrogen, which is applied in the field of capture devices, can solve the problems of difficult to achieve refrigeration temperature, high cost, poor operability, etc., and achieve the problem of heat transfer and mass transfer of surface characteristics, low cost and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

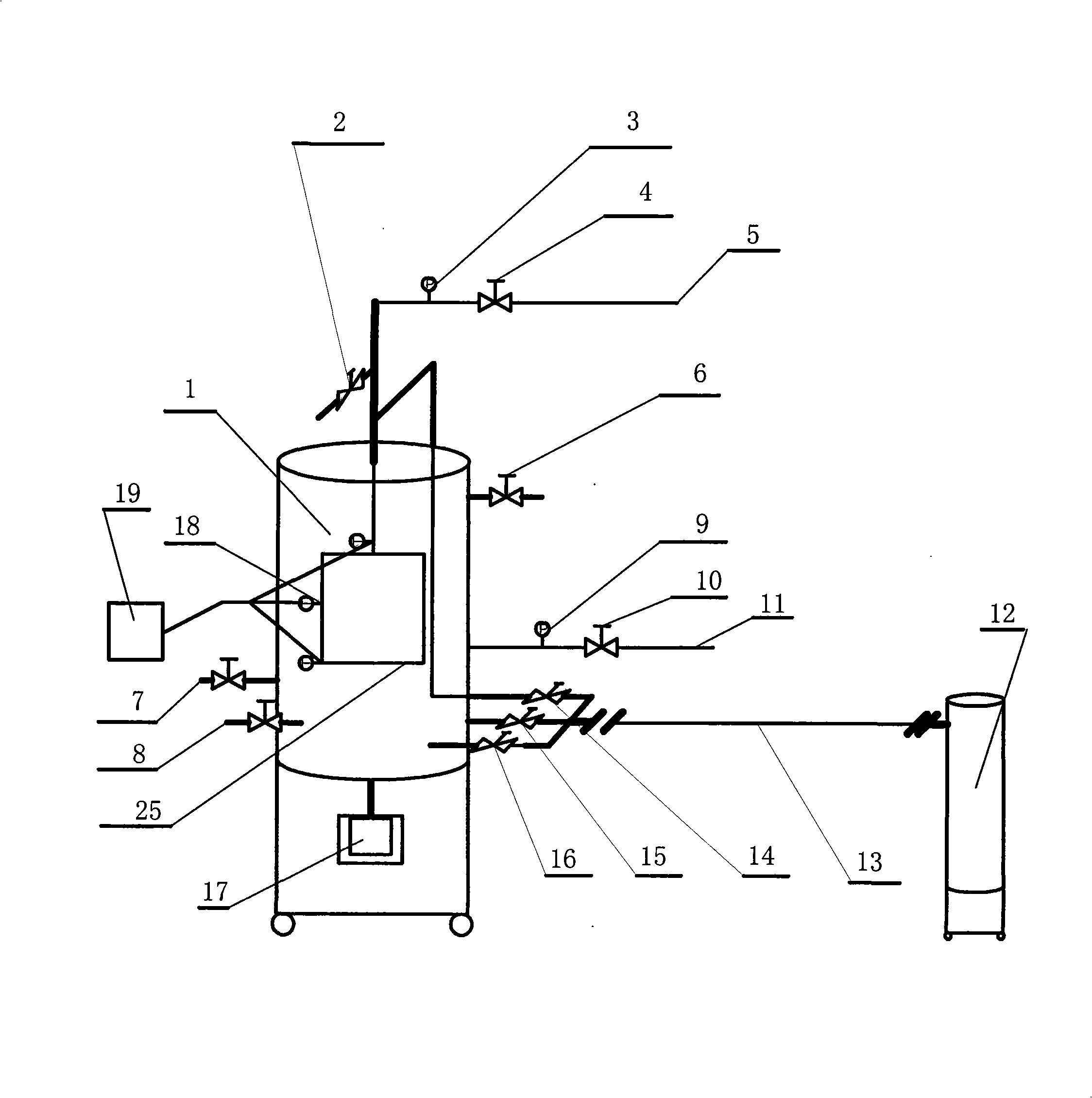

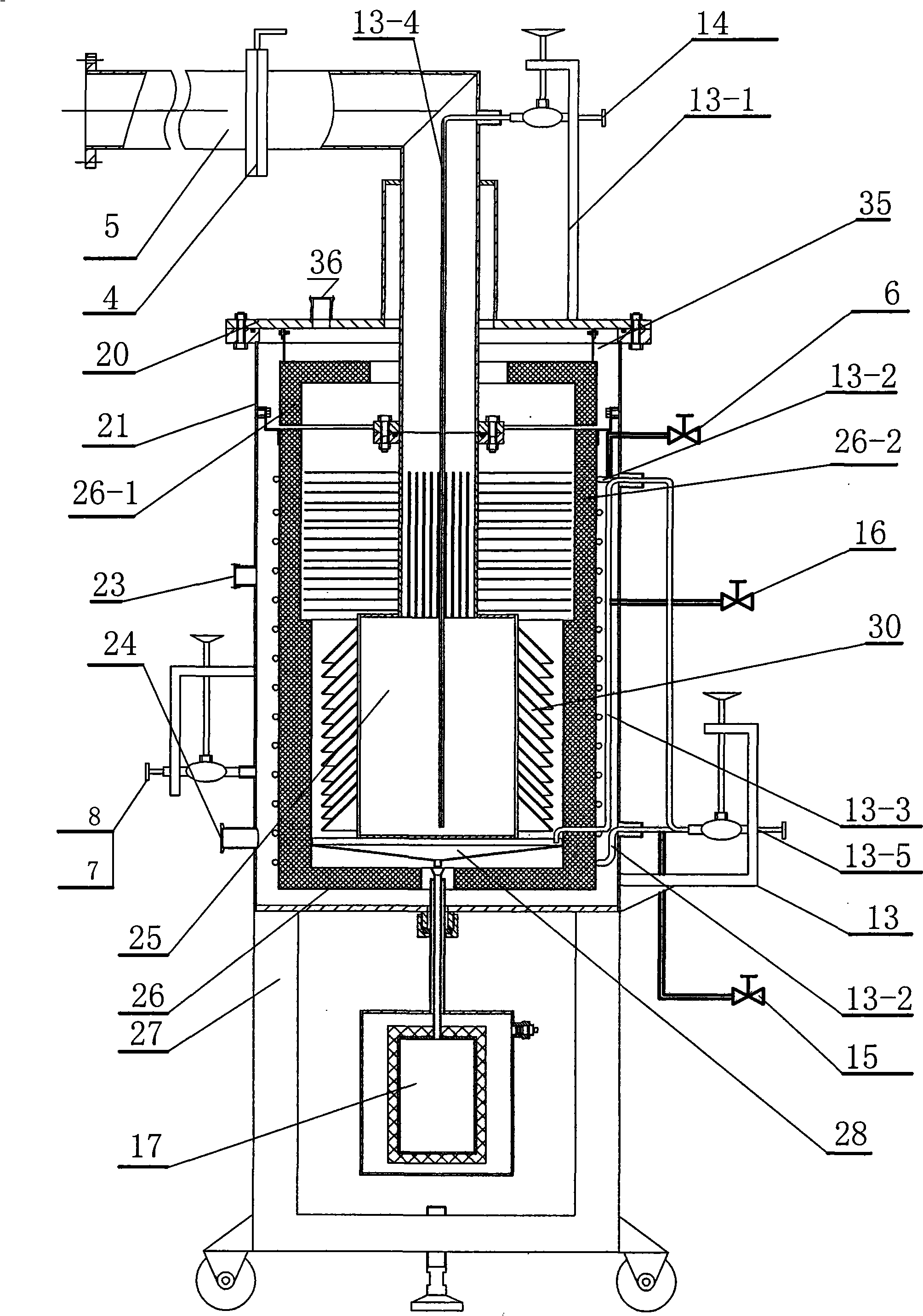

[0007] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment. The liquid nitrogen pumping refrigeration rare air condensation trapping device in this embodiment includes a bracket assembly 27, a condensation trapping tank 1, a data acquisition module 19, a nickel-chromium-gold-iron thermocouple 18, and a nitrogen extraction Pipe 5, air extraction pipe 11, liquid nitrogen delivery pipe assembly 13, liquid nitrogen Dewar 12, liquefied air collection Dewar 17, liquefied air collection plate 28, the condensation trapping tank 1 is installed on the bracket assembly 27 The upper end; the condensation trapping tank body 1 includes an outer barrel 21, an outer barrel cover 20, a cold screen assembly 26, and a liquid nitrogen chamber 25. The cold screen assembly 26 is installed in the outer barrel 21, and the outer barrel cover 20 covers the outer barrel 21 and is airtightly connected with the upper end of the outer barrel 21, the cold shield assem...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 with figure 2 To describe this embodiment, the outer tub 21 in this embodiment is provided with a first sensor interface 23 , and the outer tub lid 20 is also provided with a second sensor interface 36 . This design makes it easy to install the sensor. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the liquid nitrogen delivery pipe assembly 13 in this embodiment is composed of a straight pipe 13-4, a first pipe 13-1, a second pipe 13-2, a third pipe 13-3, an overall Pipeline 13-5, needle valve 14, cold screen valve 15, cavity pre-cooling valve 16, the main pipeline 13-5 is connected with the first pipeline 13-1, the second pipeline 13-2, and the third pipeline respectively. The pipeline 13-3 is connected, the first pipeline 13-1 is provided with a needle valve 14, the second pipeline 13-2 is provided with a cold screen valve 15, and the third pipeline 13-3 is provided with a cavity precooling valve 16. The straight pipe 13-4 communicates with the first pipeline 13-1, the second pipeline 13-2 is wound on the outer surface of the cold screen assembly 26, and the third pipeline 13-3 connects with the liquefied air collecting Dewar 17 connected. The liquid nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com