Tunnel type waste heat recovery semiconductor power generation method and device by temperature difference

A technology of waste heat recovery and temperature difference power generation, applied in the direction of generators/motors, electrical components, etc., can solve problems such as unsuitable recovery of waste heat, achieve the effect of improving thermoelectric conversion efficiency, easy promotion and application, and reducing energy consumption of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

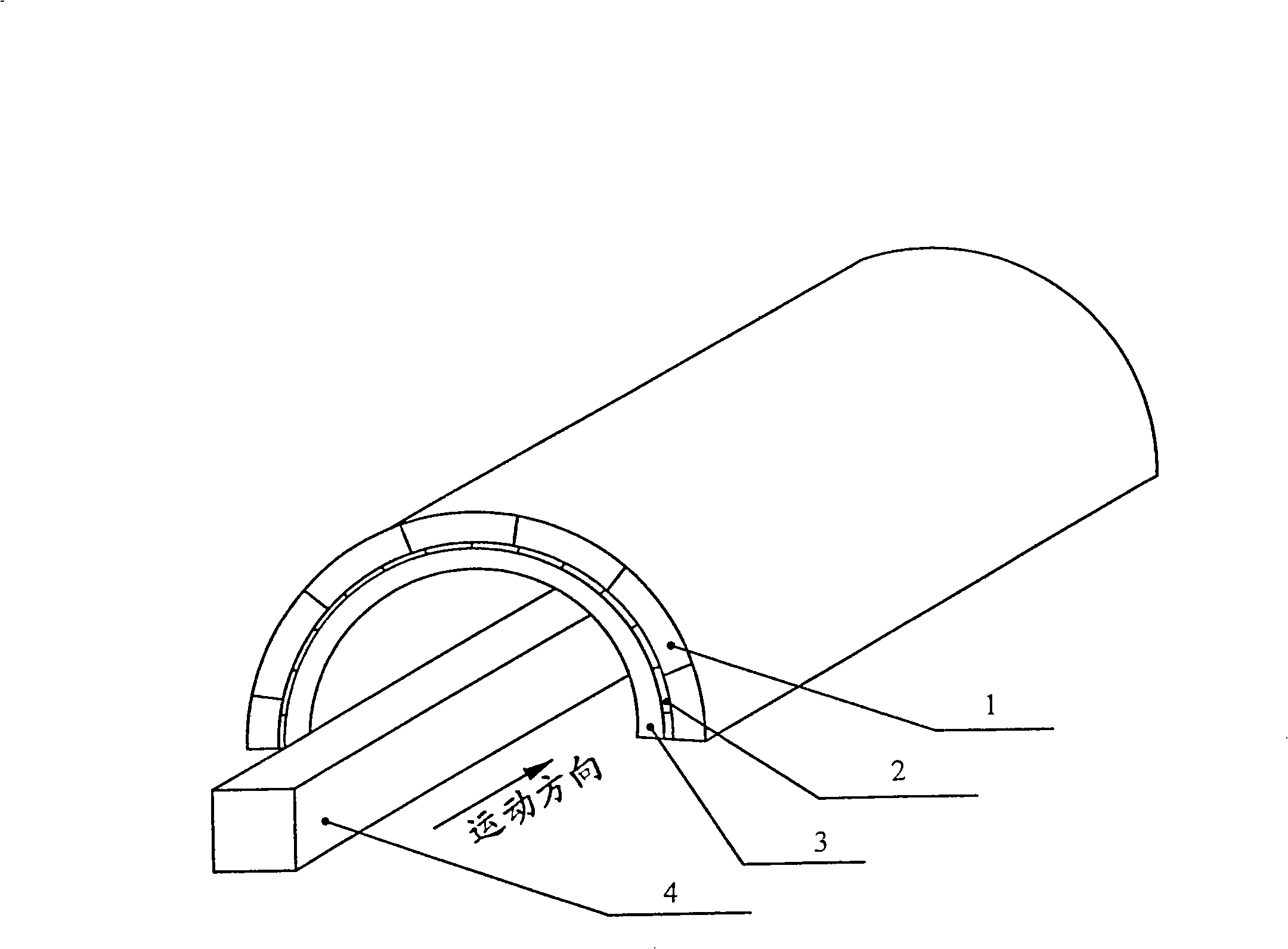

[0011] Control attached figure 1 , its structure includes a semiconductor thermoelectric power generation module 1, a tunnel collector 2, and a radiator 3. Among them, the semiconductor thermoelectric power generation module 1 is sandwiched between the tunnel heat collector 2 and the radiator 3, the tunnel heat collector 2 is closely attached to the hot surface below the semiconductor thermoelectric power generation module 1, and the radiator 3 is closely attached to the semiconductor thermoelectric power generation module 1 On the upper cold surface, the semiconductor thermoelectric power generation module 1, the tunnel collector 2, and the heat sink 3 are mechanically fastened to each other closely so as to minimize the contact thermal resistance and improve the efficiency of heat transfer. The semiconductor thermoelectric power generation module is tightly sandwiched between the tunnel collector and the radiator.

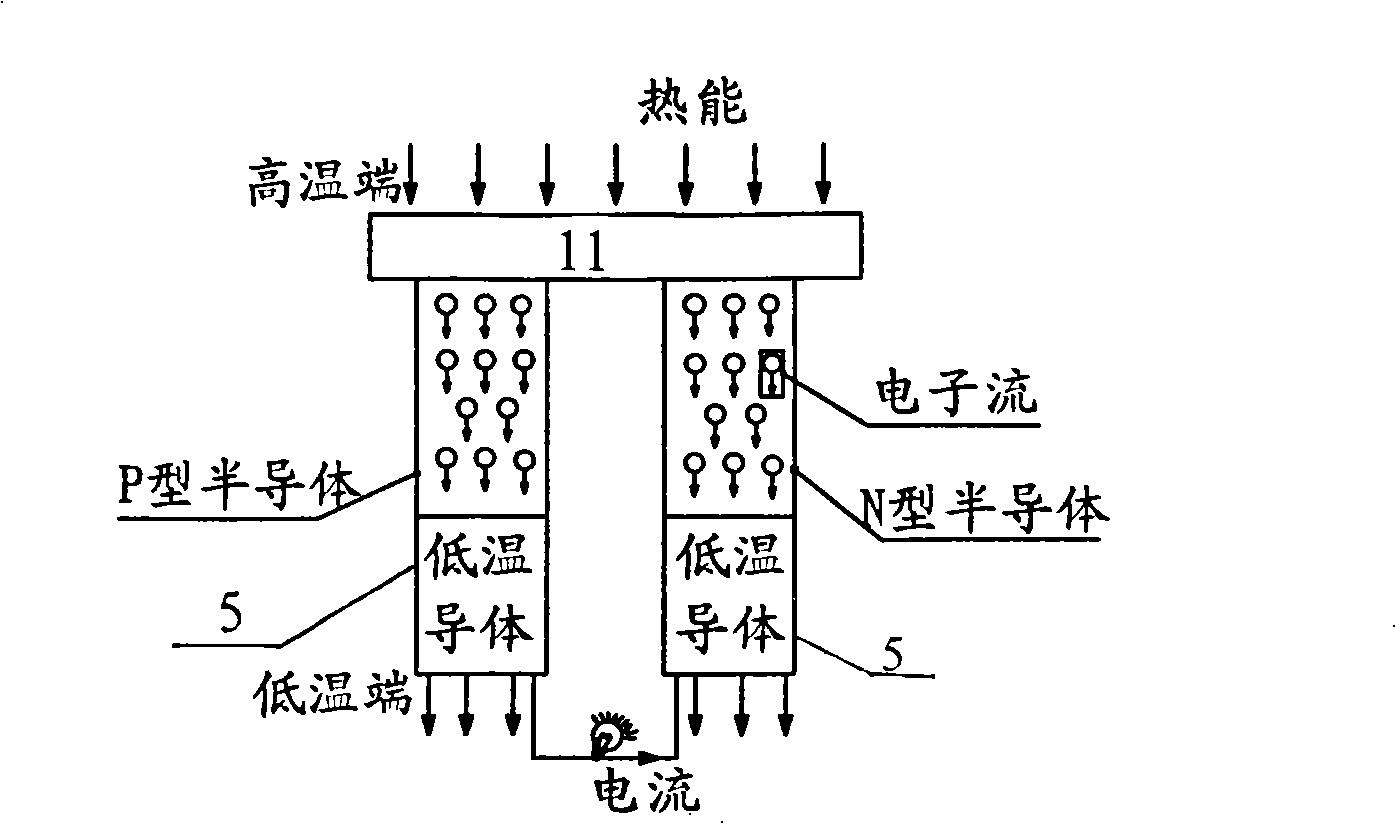

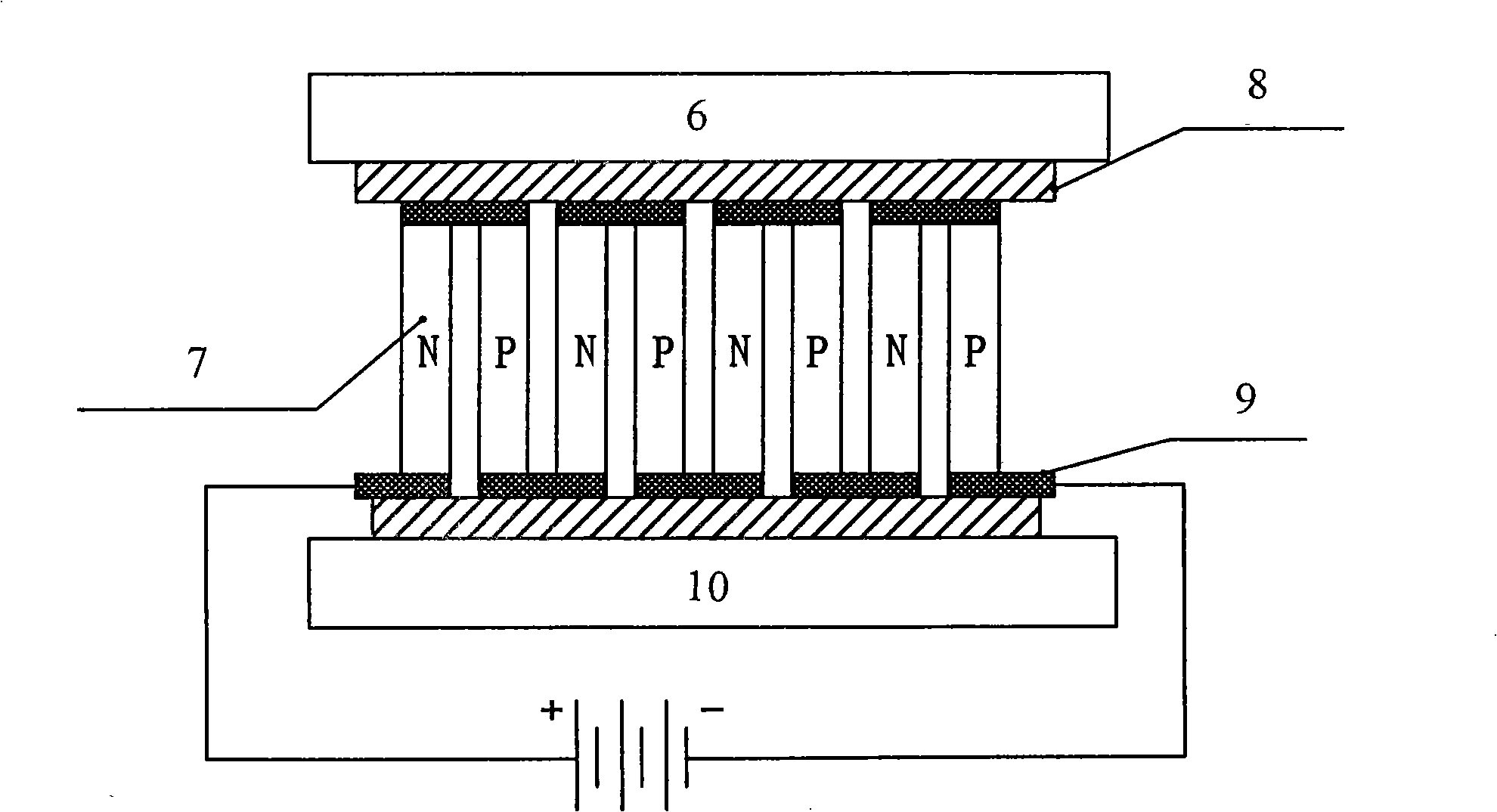

[0012] The semiconductor thermoelectric power generation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com