Digestion method and detection method of titanium-rich material

A detection method and technology for titanium-rich materials, which are used in material excitation analysis, preparation of test samples, thermal excitation analysis, etc., can solve the problems of long analysis period, high analysis cost, high sulfuric acid density, etc., and achieve efficient and fast digestion. Test the effect of simple solution and low salt concentration

Inactive Publication Date: 2010-11-24

PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, X-ray fluorescence spectroscopy (XRF) is the most commonly used method for detecting impurities in titanium-rich materials such as high-titanium slag. However, XRF method is a constant analysis method, which is only suitable for detecting the content in some low-grade and high-impurity titanium-rich materials. Impurities above 1% are useless for impurities in the range of 0.5% to 0.001% in high-grade titanium-rich materials, and the pretreatment of the sample uses about 15g of expensive lithium tetraborate as a flux at 1000°C or more Long-term melting and digestion reaction under high temperature conditions, the influence of the blank background is great, the analysis cost is high, and the inspection cycle is long

Although the inductively coupled plasma atomic emission spectrometry (ICP-AES) method has the ability to analyze impurities in the range of 15% to 0.001% in terms of technical performance, the key point is that there is currently a lack of matching titanium-rich material samples. Pre-digestion treatment method

The melting digestion reaction method commonly used by XRF cannot be used in the ICP-AES method at all. Now the wet digestion method generally uses a large amount of sulfuric acid, hydrochloric acid, hydrofluoric acid and other reagents, and heats the sample at a high temperature until sulfuric acid fumes are processed. This method can only barely meet the needs of some element detection, and fundamentally it is not a digestion method suitable for the detection and analysis requirements of ICP-AES. expedient

The current digestion method for titanium-rich materials has the following disadvantages: ①The impurities that can be detected are limited. Due to the constraints of the digestion method, many important impurities in titanium-rich materials that affect product performance cannot be detected, such as unsuitable for detection and easy to generate insoluble sulfate. Ca, oxides such as Al2O3, SiO2, Cr2O3, etc. that cannot be effectively digested by acid under normal conditions; ②Because the high-matrix Ti is easily hydrolyzed to form precipitates, wrapping the element to be measured or blocking the analysis instrument, the digestion solution must be supplemented with hydrochloric acid and kept 30% Acidity increases the impact of the blank and the corrosion of the instrument's sampling system; ③ sulfuric acid has a high density, high viscosity, high boiling point, and large dosage (usually 10mL-15mL), so the high salt concentration of the solution, matrix effect, etc. Seriously interfere with transmission, atomization and excitation efficiency; ④The digestion effect varies with product raw materials, processes, and grades. Low-grade titanium-rich materials can basically be digested completely after long-term high-temperature reaction, but the actual effect of digesting high-grade titanium-rich materials is not As expected, the higher the grade, the longer it takes, and even many samples are incompletely digested

In short, the existing analysis methods for titanium-rich materials mainly have shortcomings and limitations such as few types of detected elements, narrow coverage concentration range, complex digestion and processing methods, many interference factors, and long analysis cycle.

The application of ICP-AES method in the detection and analysis of titanium-rich materials such as high-titanium slag is still immature and incomplete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

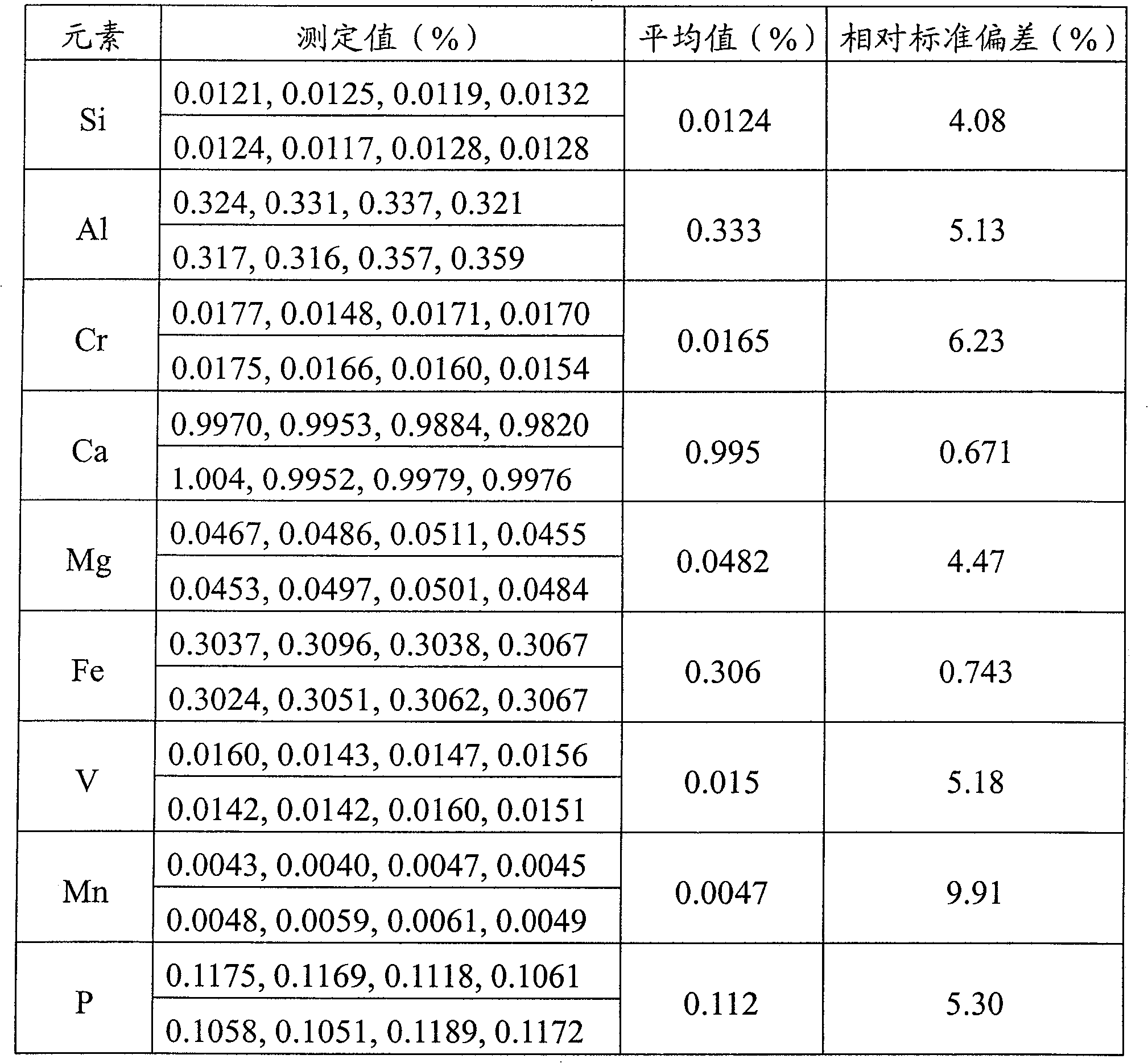

The invention provides a method for digesting a rich titanium product and a method for detecting the rich titanium product. The method comprises the following steps: placing a sample of the rich titanium product in a container; adding nitric acid, hydrochloric acid and hydrofluoric acid into the container; sealing the container; conducting digestion with microwave to obtain a digestion solution. The method comprises the step of adopting an inductively coupled plasma atomic emission spectrometer to detect the digestion solution prepared through the above steps. According to the digesting method and the detecting method, a plurality of key impurities with the content ranging from 15% to 0.001%, which determine the quality of the rich titanium product, can be simultaneously detected. Furthermore, the accuracy, the precision and the working efficiency of detection data are greatly improved.

Description

Digestion method and detection method of titanium-rich material technical field The present invention relates to a digestion method and detection method for titanium-rich materials, in particular to such a digestion method and detection method, that is, the digestion method can quickly and completely digest titanium-rich materials, and the detection method can simultaneously detect a content range of 15% ~0.001% of various impurities that determine the quality of titanium-rich materials. Background technique The first process of producing titanium dioxide from ilmenite with a TiO2 content (weight content, the same below) of 45% to 70% by the chlorination method is to separate titanium from ilmenite containing a large amount of iron and other impurities. To obtain the so-called "titanium-rich material" (TiO2 content can be as high as 95%) with higher TiO2 content and less impurity elements as a raw material for the titanium industry. Research on the method of enriching ilm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N1/28G01N1/44G01N21/73

Inventor 成勇

Owner PANGANG GROUP RESEARCH INSTITUTE CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com