Method of producing stalk composite fiber material for road

A technology of composite fibers and straws, which is applied in fiber raw material treatment, non-fiber pulp addition, inorganic compound addition and other directions, can solve the problems of difficulty in removing waste paper ink, unstable raw material quality, unstable product quality, etc., and improve oil absorption. efficiency, solve unstable performance, and easy to industrialize the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

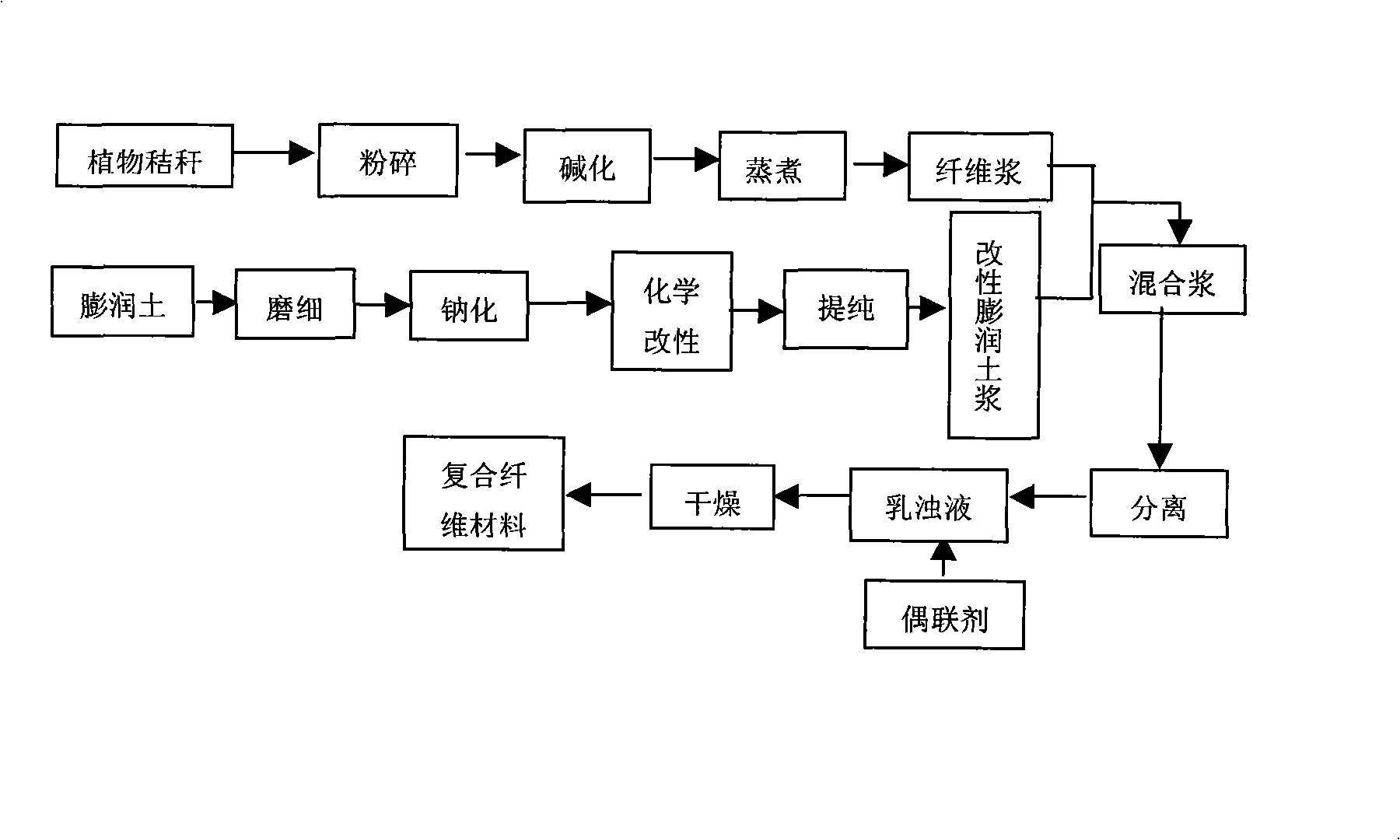

Method used

Image

Examples

example 1

[0025] Example 1: Utilize corn stalks to make composite fiber materials, the steps are:

[0026] (1) Choose non-rotten corn stalks, remove the leaves, ears, and roots, wash and remove the surface dirt, and soak for one hour, then take out the stalks and cut them into about 100mm, and store them under the condition of maintaining their humidity spare.

[0027] (2) Use a fiber processing machine to process the stored straw into crude fiber.

[0028] (3) Soak the crude fiber in a NaOH solution with a concentration of 0.08mol / L to 0.15mol / L for 3 to 4 hours, then remove the soaked crude fiber to the cleaning tank, and inject CO into the cleaning tank 2 And measure the pH value of the cleaning tank to 6.4-7.6.

[0029] (4) Cook the crude fiber with adjusted pH value for 310 minutes, and the cooking ingredients are composed of corn stalk crude fiber, NaOH solution, NaOH solution, 2 S·9H 2 O, the weight ratio of water is 10:4:1:100, and utilize fiber machine to beat fine fiber sl...

example 2

[0036] Example 2: Utilize rice straw to make composite fiber material, the steps are:

[0037] (1) Choose non-rotten rice straw, remove the leaves, ears, and roots, wash and remove the surface dirt, and soak for one hour, then take out the straw and cut it into about 100mm, and store it under the condition of maintaining its humidity spare.

[0038] (2) Use a fiber processing machine to process the stored straw into crude fiber.

[0039] (3) Soak the crude fiber in a NaOH solution with a concentration of 0.12mol / L for 3 hours, then remove the soaked crude fiber to the cleaning tank, and inject CO into the cleaning tank. 2 And measure the pH value of the cleaning tank to 7.6.

[0040] (4) The crude fiber with adjusted pH value was steamed for 10 minutes, and the steamed ingredients consisted of rice straw crude fiber, NaOH solution, NaOH solution, and NaOH solution. 2 S·9H 2 O, the weight ratio of water 10: 4: 1: 200, and utilize fiber machine to make fine fiber pulp.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com