Reaction system and preparation method for nitrous alkyl ester

A technology of alkyl nitrite and reaction system, which is applied in the direction of preparation of nitrite, chemical method for reacting liquid and gaseous medium, chemical instruments and methods, etc., can solve the problem of intensified side reactions and the process of alkyl nitrite Complications and other problems, to achieve the effect of mild operating conditions, convenient continuous production, high conversion rate of raw materials and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The trickle bed reactor is a heterogeneous fixed bed reactor in which the gas-liquid two-phase co-current (or countercurrent) contacts the catalyst or packing at the same time. In the trickle bed reactor, the liquid passes through the packed bed layer downwards, and the gas reacts Pass through concurrently (or countercurrently). In the co-current trickle bed reactor, both the gas and liquid phases flow downward, the gas is the continuous phase, the liquid is the dispersed phase, and the liquid flows down along the surface of the catalyst or solid packing in the form of droplets or liquid film; in countercurrent In a trickle bed reactor, the continuous upward flow of gas is opposite to the downward flow of the dispersed liquid phase.

[0017] The main advantages of a trickle bed are:

[0018] (1) The gas-liquid flow is close to the plug flow, and a higher conversion rate can be obtained;

[0019] (2) The liquid flows in the form of a film, so that the resistance of the...

Embodiment 2

[0032] Under the completely identical situation of other conditions and embodiment 1, change liquid phase ethanol and gaseous phase NO, O 2 The feeding mode of the method is a countercurrent mode, and the regeneration reaction of ethyl nitrite is carried out to form the reaction result of Example 2.

[0033] Table 2: Comparison of two gas-liquid phase mixing methods (reaction temperature 60°C)

[0034]

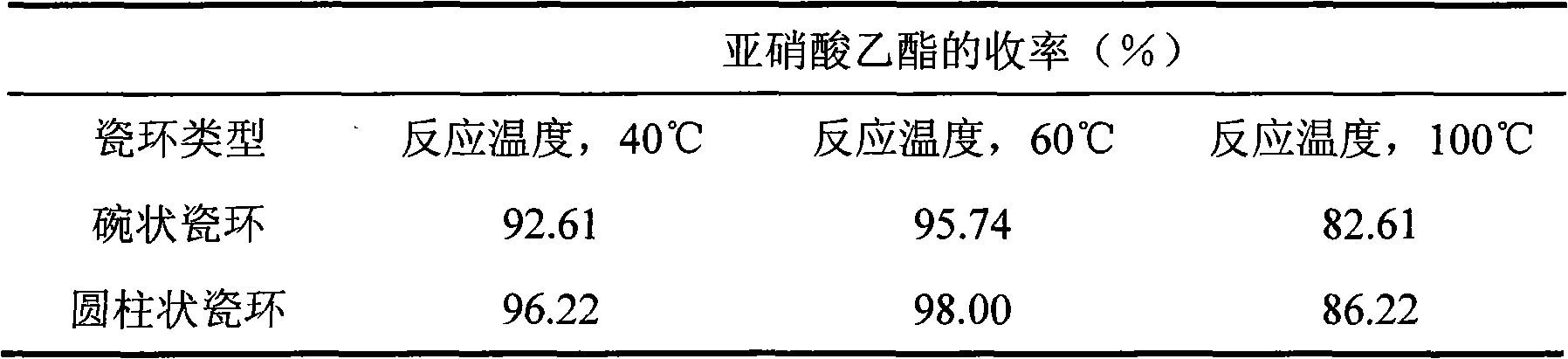

Embodiment 3

[0036] Under the completely identical situation of other conditions and embodiment 1, change NO and O 2 The feed molar ratio, carry out ethyl nitrite regeneration reaction, form the reaction result of embodiment 3 as shown in table 3.

[0037] Table 3: NO and O 2 Comparison of Feed Molar Ratio

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com