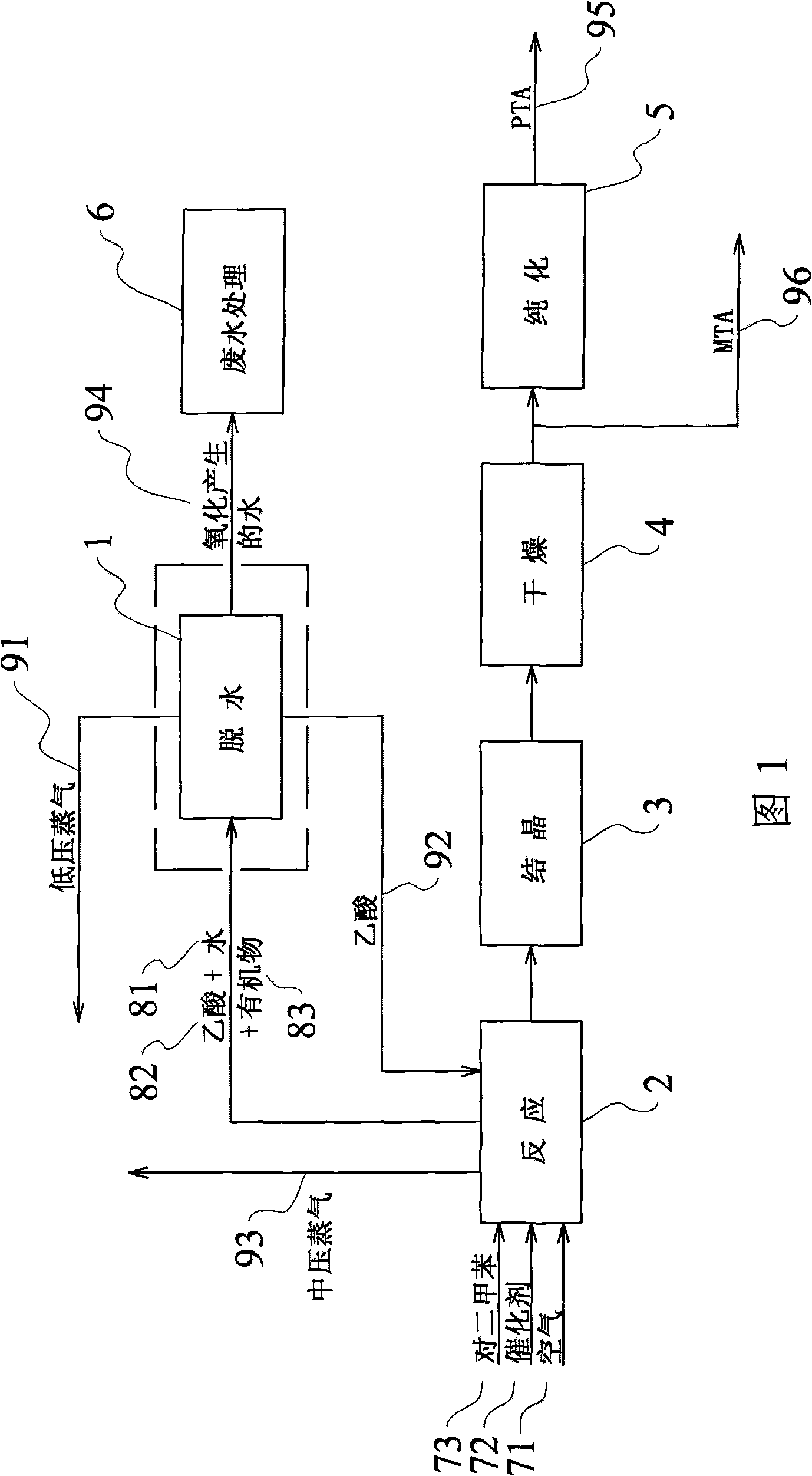

System and method for acetic acid dehydration

A kind of technology of acetic acid and distillation system, applied in the field of chemical process of distilling industrial chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

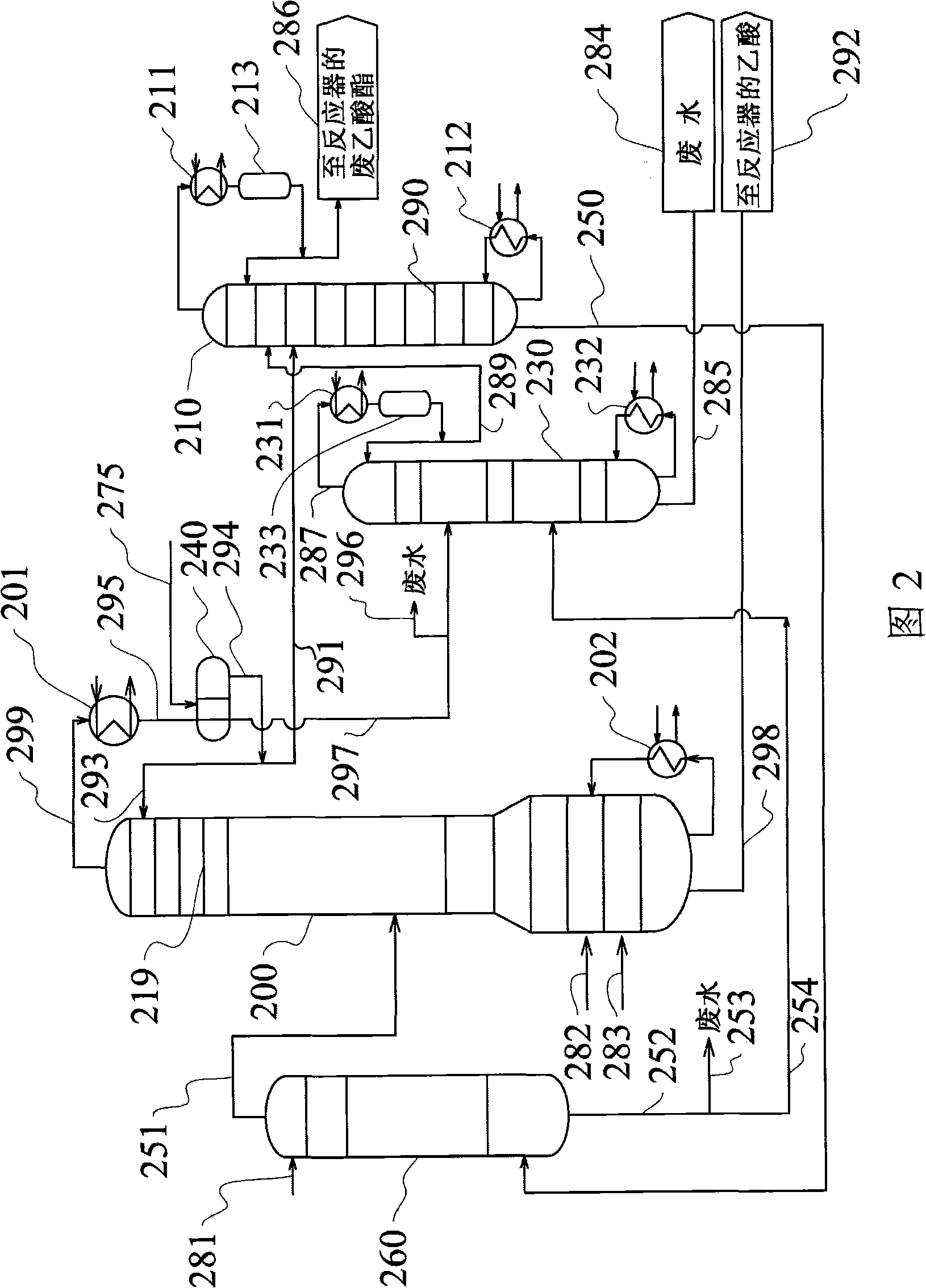

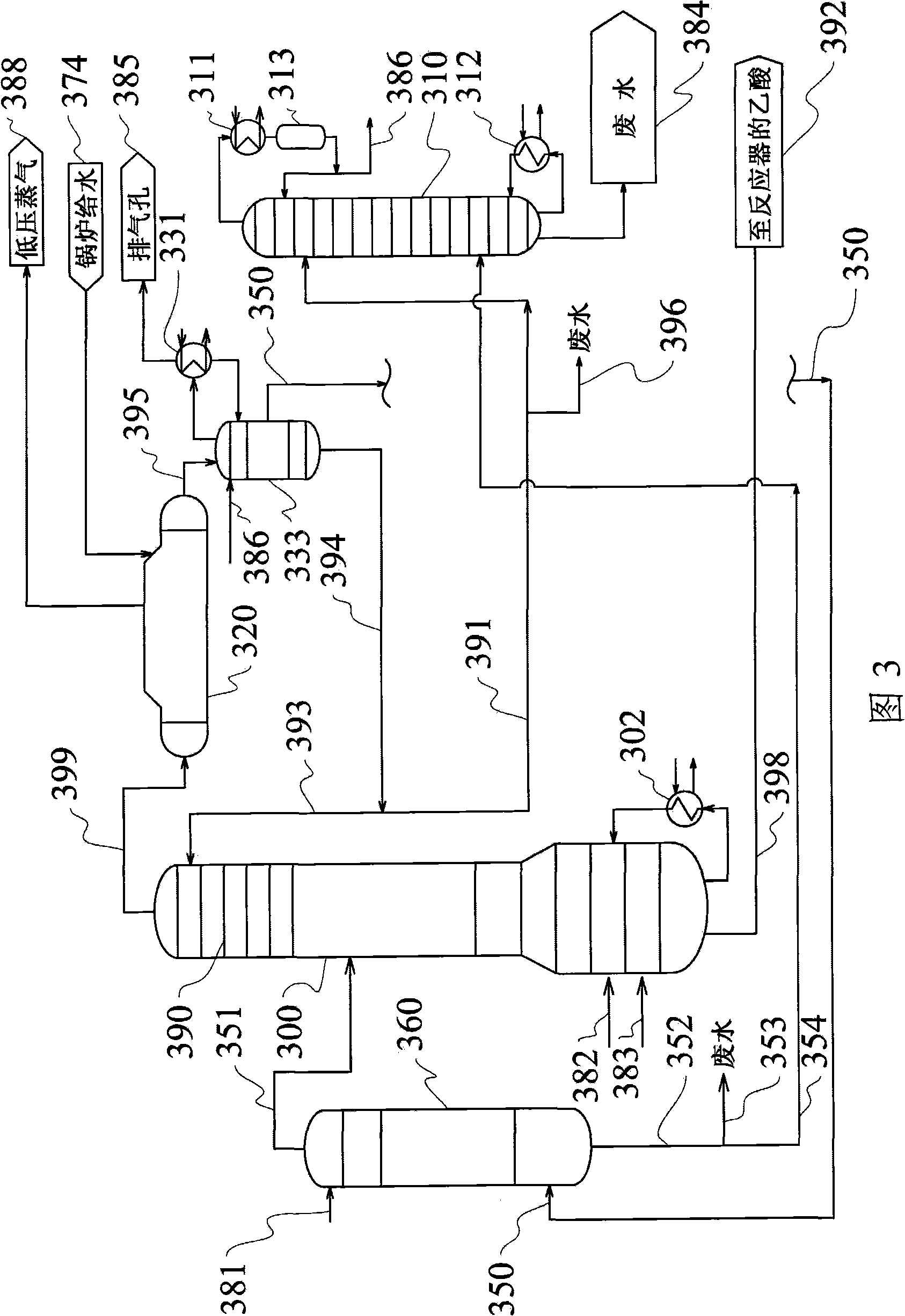

Method used

Image

Examples

Embodiment

[0043] This example illustrates several benefits of the present technology using an extraction column compared to traditional distillation and azeotropic acetic acid dehydration techniques that do not use an extraction column. In particular, all three technologies are integrated in a typical 350,000 MTA terephthalic acid manufacturing facility to determine their different operational requirements and efficiencies. In this example, all distillation columns had 90 trays; conventional and azeotropic distillation columns were operated at ambient pressure. Various design and general operating parameters are given below.

[0044] Parameters Conventional Distillation Azeotropic Distillation Invention

[0045] azeotrope no yes yes

[0046] Extraction solvent no no yes

[0047] Number of trays in dehydration distillation column 90 90 90

[0048] System steam consumption (tons / hour) 60 42 36

[0049] Acetic acid sent to wastewater treatment (WWT)

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com