Flat type evaporator radiation system

A flat plate evaporator and heat dissipation system technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. and other problems to achieve the effect of reducing the startup temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be fully understood from the following examples, so that those skilled in the art can complete it, but the implementation of the present invention should not be limited by the following examples.

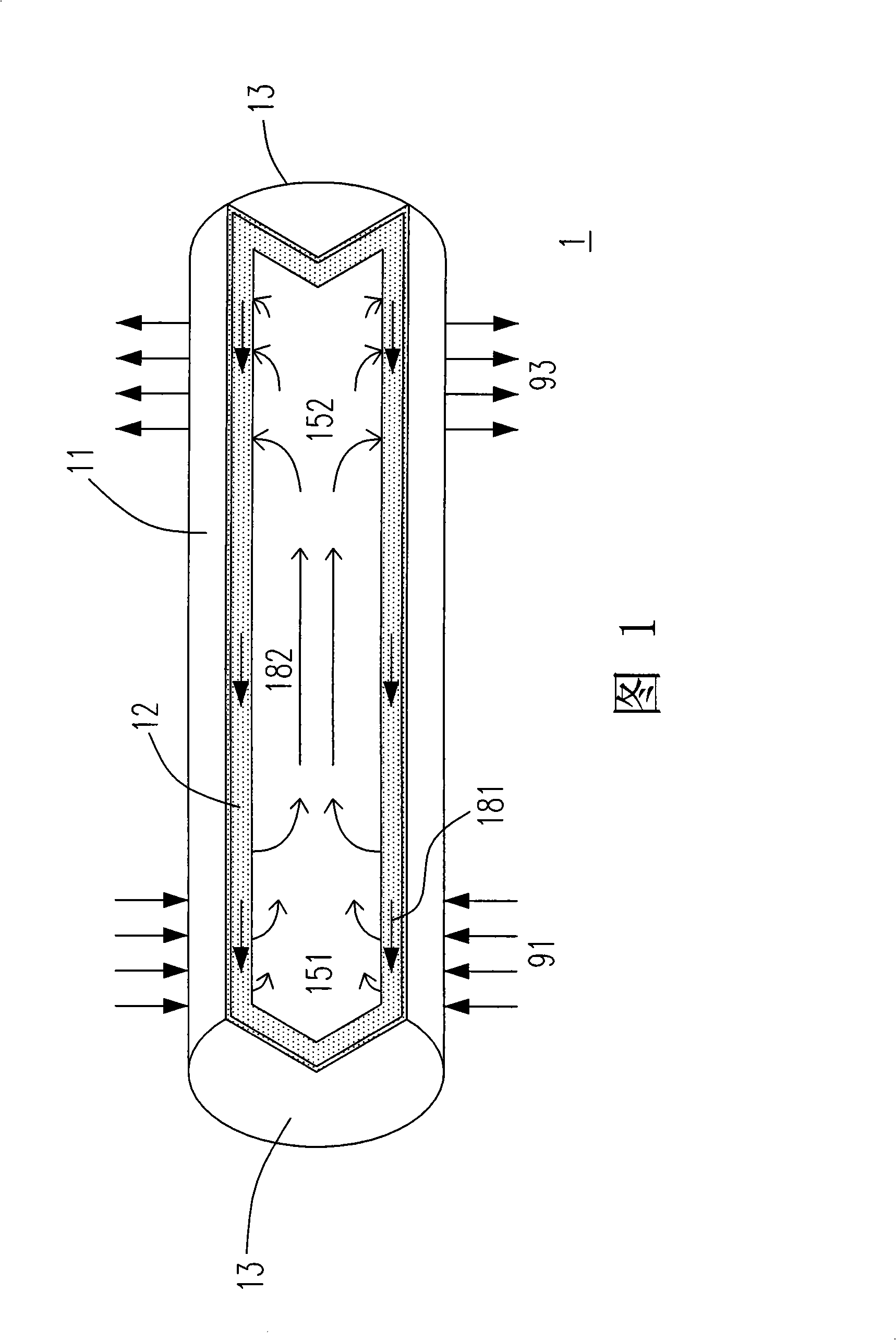

[0089] Please refer to FIG. 3 , which is a schematic diagram of the first embodiment of the cooling system of the present invention. In Fig. 3, a cooling system 3 includes an evaporator 31, a steam channel 33, a condensate channel 35 and a condensation area 37, wherein the evaporator 31 is a flat shell tank 310, which is composed of upper and lower covers, Usually made of a metal alloy with good thermal conductivity, it is used to be close to or in contact with an external heat source 91 to bear its thermal energy, and it includes a first capillary structure (WickStructure) 311, a steam channel 313 and a compensation chamber (Compensation Chamber) 315, and after vacuumizing, inject a liquid that is easily evaporated under a low pressure as a condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com