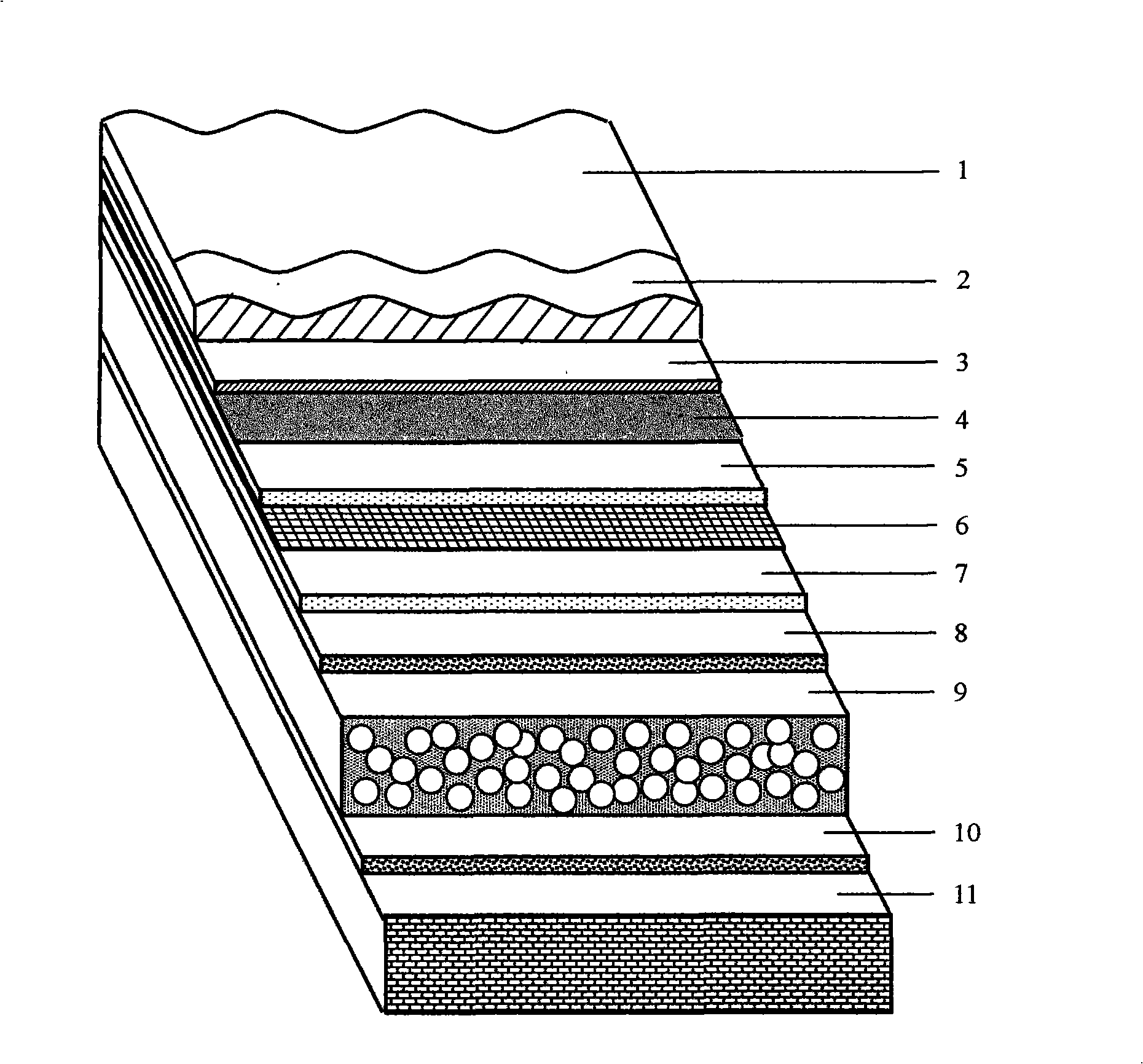

Thermal insulation and water proof integrated system of roof covering and construction method thereof

A technology of waterproof layer and thermal insulation layer, applied in the direction of roof covering layer, building roof, etc., can solve the problems of waterproof, reduced thermal insulation performance, material matching between layers, etc., to improve work efficiency, matching and good bonding performance , the effect of enhancing crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The polymer cement waterproof mortar used in the first and second waterproof layers is prepared from the following components based on 100 kg of mortar: 25 kg of styrene-acrylic acid copolymer emulsion with a solid content of 50%, 46 kg of 425# cement, 200 20 kg of quartz sand, 0.15 kg of defoamer (using 1922, purchased from Corning Cognis company), 0.15 kilograms of methyl hydroxyethyl cellulose ether (using MKX 40000PF from Wolff Cellullosics), and water 8.7 kg.

[0056] The preparation process of styrene-acrylic acid copolymer emulsion is as follows: add an appropriate amount of deionized water and emulsifier to the reactor, stir and heat up to about 80°C, add 1 / 3 of the mixture of styrene, butyl acrylate and acrylic acid, and react for about 30 minutes , add the initiator and the remaining mixed monomer dropwise, keep the temperature at about 83°C, finish the dropwise addition in about 2 hours, raise the temperature to about 88°C, keep it warm for 1 hour, stir an...

Embodiment 2

[0078] The polymer cement waterproof mortar used in the first and second waterproof layers is prepared from the following components based on 100 kg of mortar: 17.90 kg of styrene-acrylic acid copolymer emulsion with a solid content of 50%, 35.70 kg of 425# cement, 200 17.85 kg of quartz sand, 0.76 kg of defoamer (using 1922, purchased from Corning Cognis company), 1.0 kilograms of methyl hydroxyethyl cellulose ether (using MKX 40000PF from Wolff Cellullosics), and water 26.79 kg.

[0079] The rubber powder polystyrene particle cement mortar used in the insulation layer is prepared by mixing 100L of polystyrene particles with the following components: 5.00 kg of 425# cement, 4.50 kg of 200 quartz sand, and 0.50 kg of vinyl acetate-ethylene redispersible latex powder (use FX2350, purchased from Elotex), 0.1 kg of water reducer (using F10, available from Degussa Company), 0.05 kg of defoamer (using 1922, purchased from Corning Cognis company), 0.15 kilograms of methyl h...

Embodiment 3

[0084] The polymer cement waterproof mortar used in the first and second waterproof layers is prepared from the following components based on 100 kg of mortar: 33.00 kg of styrene-acrylic acid copolymer emulsion with a solid content of 50%, 44.00 kg of 425# cement, 200 22.00 kg of quartz sand, 0.4 kg of water reducer (using F10, purchased from Degussa Company), 0.6 kg of methyl hydroxyethyl cellulose ether (using MKX 40000PF, available from Wolff Cellullosics).

[0085] The rubber powder polystyrene particle cement mortar used in the insulation layer is prepared from 100L of polystyrene particles and the following components: 7.50 kg of 425# cement, 6.50 kg of 200 quartz sand, and 0.50 kg of vinyl acetate-ethylene redispersible latex powder (use FX2350, available from Elotex), 0.10 kg of defoamer (using 1922, purchased from Corning Cognis company), 0.15 kilograms of methyl hydroxyethyl cellulose ether (using MKX 40000PF, available from Wolff Cellullosics), 0.05 kg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impermeability pressure | aaaaa | aaaaa |

| Impermeability pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com