Wire rod for producting1770Mpa bridge cable galvanized steel wire and method for manufacturing same

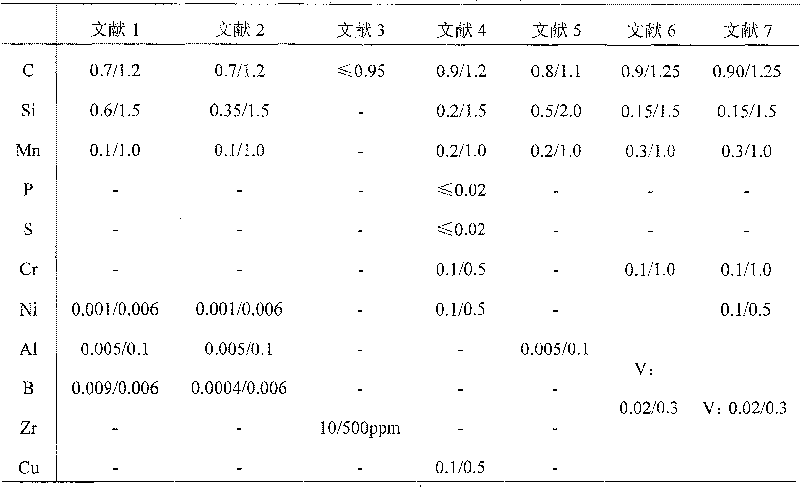

A 1770mpa, galvanized steel wire technology, used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high wire-controlled rolling and controlled cooling process control, high silicon content, martensite in wire rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

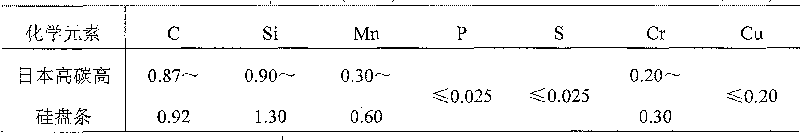

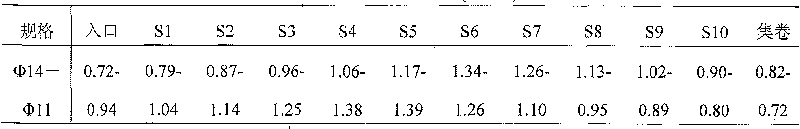

[0056] According to the contents of the chemical elements shown in Table 6, desulfurization of molten iron, converter, out-of-furnace refining, ingot pouring, followed by initial rolling soaking, billet opening, large shear head and tail, 6VH continuous rolling 142 2 , cutting to length by flying shears, mechanical cleaning of steel billets, heating in high-speed wire heating furnaces, controlled rolling on high-speed wires, controlled cooling on high-speed Steyrmo lines, wire rod surface inspection, sampling inspection, wire rod bundling, tagging, Storage, delivery. Subsequently, element content determination (see Table 8), steel billet center carbon and center carbon segregation determination (see Table 9), inclusion control measurement (see Table 10), sorbite content and decarburization layer depth control measurement (see Table 11 ).

[0057] Table 6 Chemical elements contained in high carbon steel (0.87%) (wt%)

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com