Carbon calcination fume dry cleaning method and device thereof

A technology of dry purification and smoke dust, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of reduced service life of equipment, high operating costs, and secondary pollution of the environment, so as to reduce production and operation costs, The effect of high degree of automation control and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

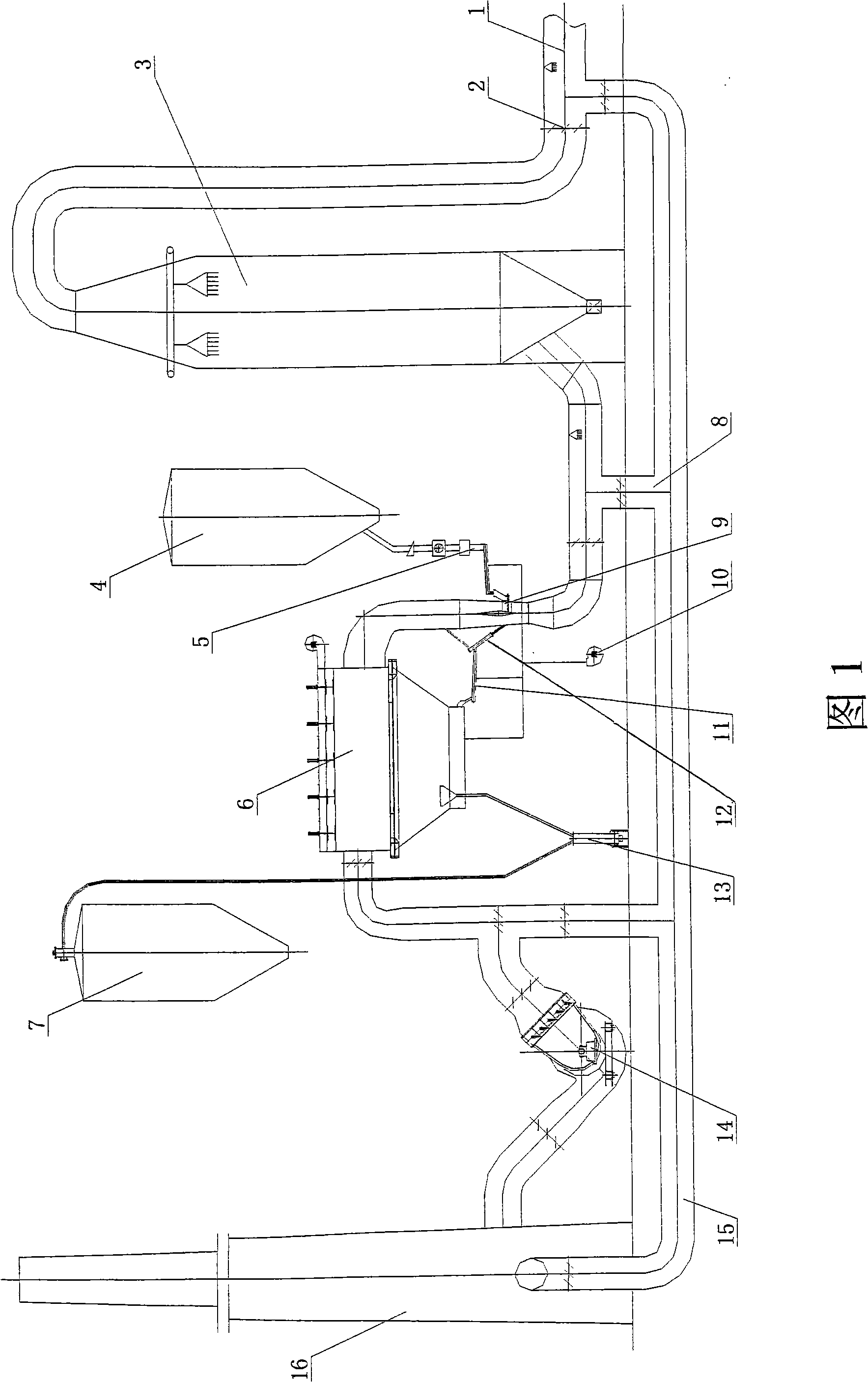

[0021] As shown in Figure 1, a kind of carbon roasting fume dry purification method, under the effect of induced draft fan 14 suction, the soot that makes roasting furnace come out enters the interior cooling of dry bottom type cooling tower 3 through valve 2 from soot pipeline 1, and soot Enter the tower from the top of the dry-bottom cooling tower for spray cooling, and the cooled soot enters the reactor 9 from the soot pipe 1 at the bottom of the tower through the valve 2, and the alumina in the fresh alumina silo 4 is transported through the fresh alumina The system 5 enters the reactor 9, where the alumina is mixed with the soot, and the alumina absorbs the tar and fluorine in the soot to purify the fluorine; the recyclable alumina in the bag filter 6 passes through the circulating alumina conveying system 12 enters the reactor 9 for recycling, and the flue dust after the reaction and alumina containing adsorbate enter the bag filter 6 for separation and filtration of gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com