Biochemical treatment process for high-concentration ammonia-nitrogen-containing waste water

A technology of ammonia nitrogen concentration and biochemical treatment, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem that nitrifying bacteria cannot tolerate high concentrations of ammonia nitrogen, low COD value of chemical oxygen demand, Low concentration of organic matter and other problems, to achieve the effect of low treatment cost, simple process and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

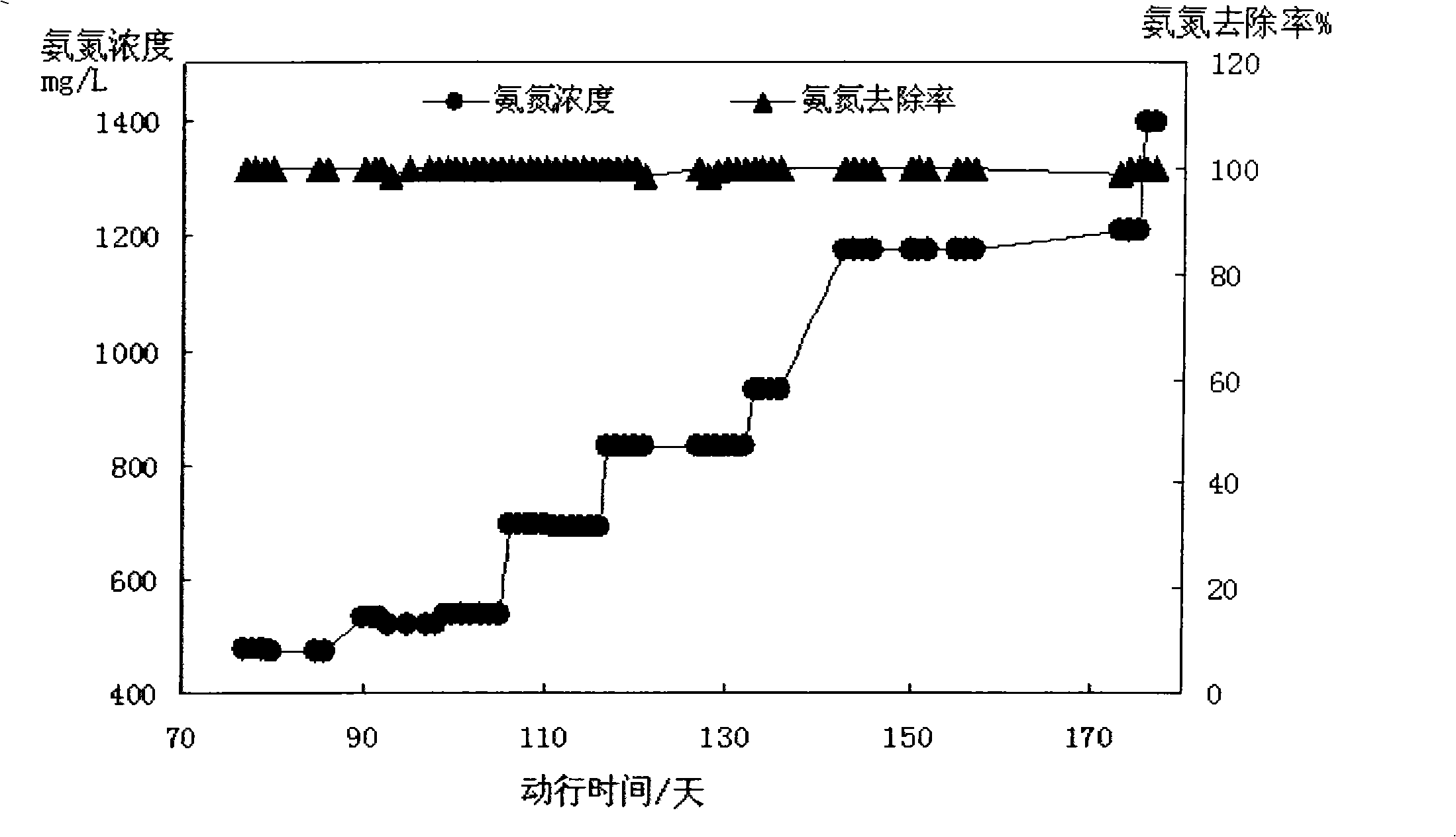

[0040] Example 1 Nitrification sludge enrichment

[0041] The enrichment culture parameters are: temperature 15-30°C; pH value 6.5-8.0; initial sludge sedimentation ratio 30V%; dissolved oxygen DO>2.0mg / l; Stop gas for 1 hour and replace with 1.5L of new culture medium. The concentration of ammonia nitrogen increases gradually with the running time, from 100mg / L to 1400mg / L, and the ammonia nitrogen load changes from 0.05Kg NH 4 + -N / m 3 d gradually increased to 1.04Kg NH 4 + -N / m 3 d.

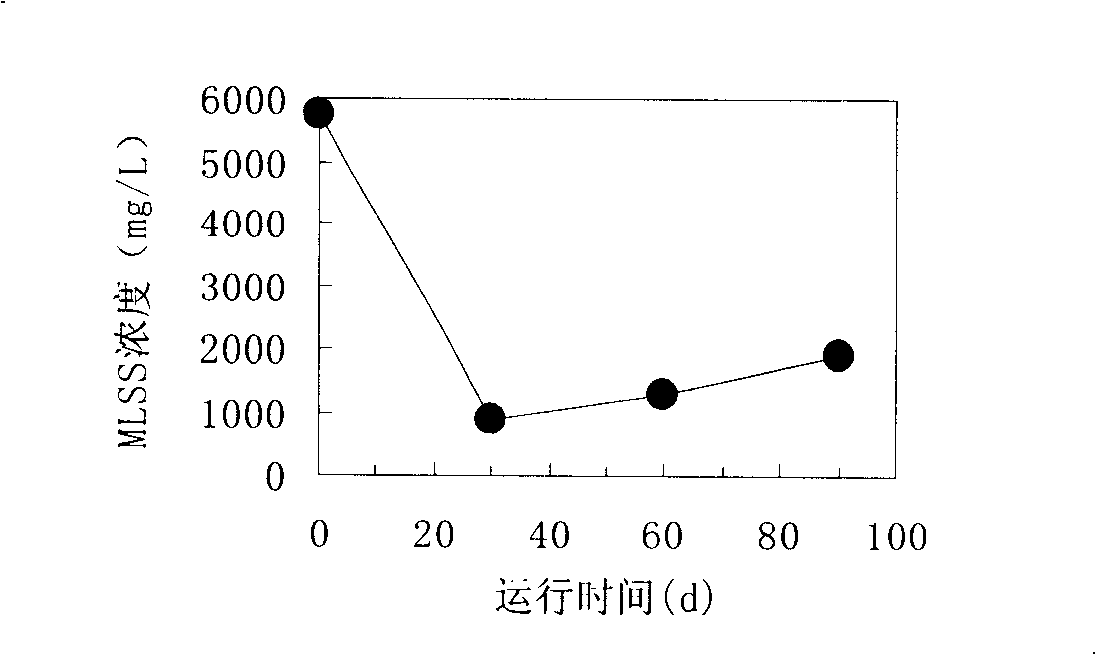

[0042] The sludge concentration MLSS in the enrichment tank was measured at 30 days, 60 days and 90 days of enrichment respectively, see figure 2. The sludge concentration in the enrichment tank gradually decreased in the early stage, from 5760mg / L at the beginning of enrichment to 876mg / L after 30 days. They cannot survive and the autolysis will be lost with daily water changes, resulting in a decrease in the total sludge concentration. When a large number of heterotrophic bacteria ...

Embodiment 2

[0048] Example 2 Enrichment of denitrification and denitrification bacteria

[0049] The enrichment parameters are: anaerobic culture, using a stirrer to stir, and the stirring rate is set to 150r / min; the temperature is 15-30°C; pH: 7.5-8.5; the initial sludge sedimentation ratio is 30%; the total volume of the reaction system is 1L, Feed in batches of water, stop stirring every 24 hours and replace with 0.5L of new water.

[0050] The SV30, SVI and denitrification rate of activated sludge after enrichment 0d and 60d were measured, see Table 2.

[0051] Table 2 Nitrogen removal rate, sedimentation ratio and volume index of activated sludge before and after enrichment

[0052]

[0053] It can be seen from Table 2 that although after a period of enrichment, due to the sufficient supply of carbon sources, the sludge concentration rises sharply. Therefore, in real industrial applications, it is necessary to often discharge sludge or inoculate it into the denitrification react...

Embodiment 3

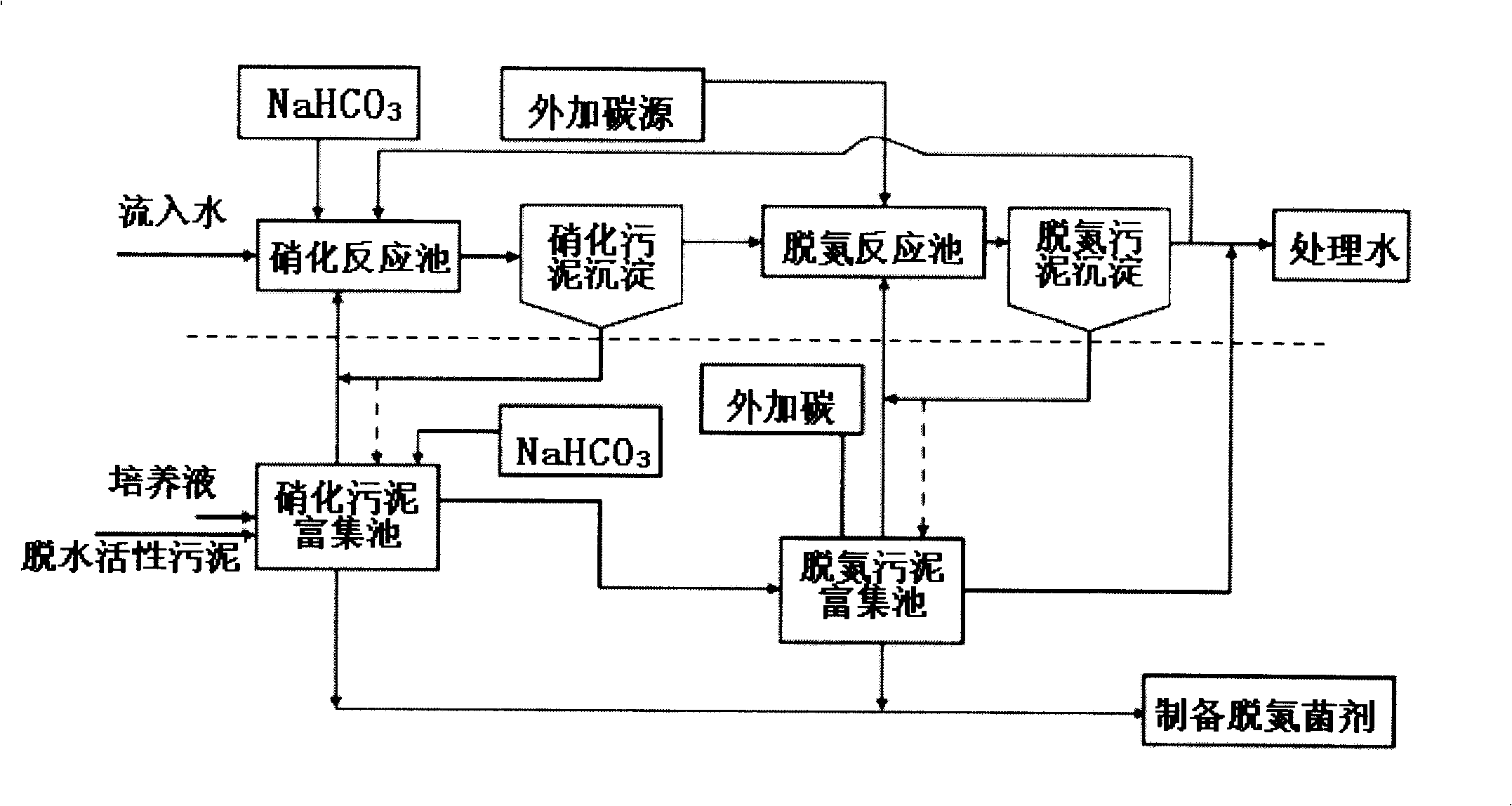

[0055] Example 3 Inoculation of enriched nitrifying bacteria / denitrifying bacteria to improve the biochemical treatment process of high ammonia nitrogen wastewater

[0056] In this embodiment, two sets of laboratory processes No.1 and No.2 are designed. No.1 only contains as figure 1 The wastewater treatment section above the dotted line (abbreviated as BT section) does not include the nitrifying bacteria / denitrification bacteria inoculation section below the dotted line (abbreviated as IND section); No.2 includes the entire BT and IND section (complete INDBT process). The reaction volumes of the nitrification reaction tank and denitrification reaction tank of No.1 and No.2 devices are both set to 4L, and the reaction volumes of the nitrification sludge enrichment tank and denitrification sludge enrichment tank of No.2 device are both set to 3L . The two devices started running at the same time, and the wastewater treated by the BT section was high ammonia nitrogen wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume load | aaaaa | aaaaa |

| Volume load | aaaaa | aaaaa |

| Volume load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com