Method for controlling start procedure of electric ballast of high-strength air discharge lamp

A technology for electronic ballasts and gas discharge lamps, applied in the field of electronic ballast start-up process control, can solve problems such as bulb deviation, achieve smooth start-up process, ensure accuracy and reliability, and protect life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

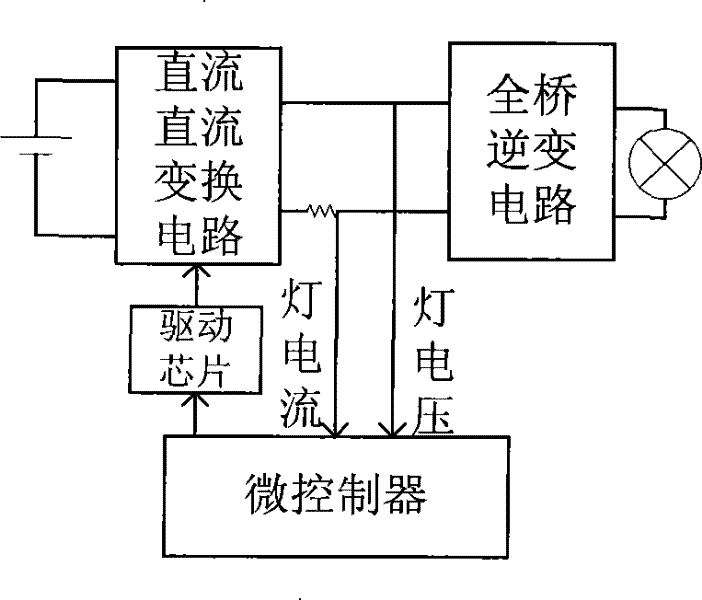

[0015] Such as figure 1 As shown, the control system of the electronic ballast start-up process control method of the present invention includes a microcontroller and a driver chip, and the microcontroller has an analog-to-digital signal converter and an EEPROM. The main circuit of the ballast includes a DC-DC conversion circuit and a full-bridge inverter circuit. The DC-DC conversion circuit boosts the DC voltage to obtain a DC voltage suitable for the bulb, and the DC voltage is converted into an AC through the full-bridge inverter circuit. Voltage is supplied to the bulb, making it work. The microcontroller is connected to the DC-DC conversion circuit and the full-bridge inverter circuit, and the drive chip is connected to the microcontroller and the DC-DC conversion circuit respectively.

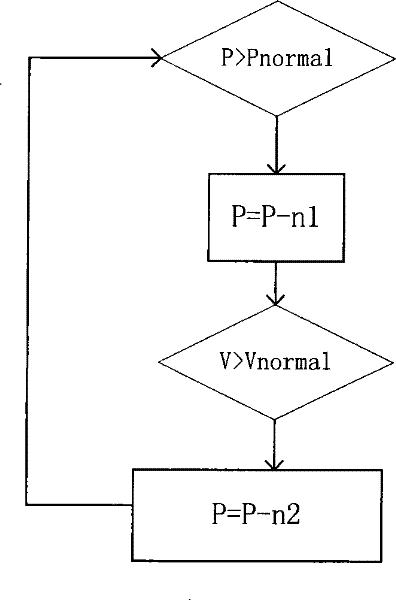

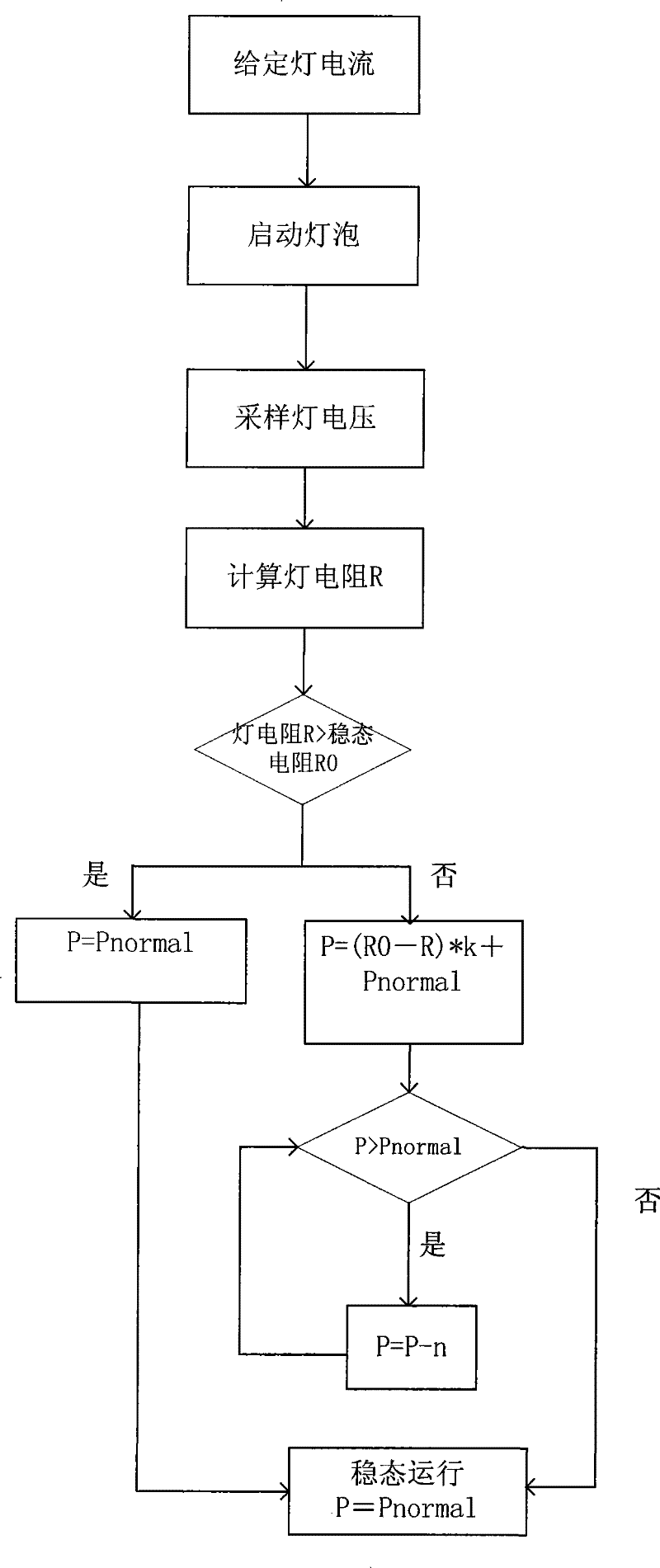

[0016] The main principle of the starting process control method of the present invention is to judge the state of the lamp according to the lamp resistance. By sampling the lamp volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com