Photolithography process including a chemical rinse

A lithography process, semiconductor technology, applied in the field of lithography process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention relates to a method of manufacturing a semiconductor device, and in particular to a photolithography process with a chemical cleaning process. It should be understood that the specific embodiments hereinafter are presented to illustrate the concept of the invention and enable those skilled in the art to practice the invention. In addition, it should also be understood that the operating methods and devices disclosed in the embodiments of the present invention may include certain known processes or structures. When these known structures or processes are mentioned in the embodiments, the descriptions of their detailed parts are only for general discussion. In addition, repeated use of the same reference number for the same device in the drawings is for convenience of description, rather than representing any combination of structures or steps in the drawings.

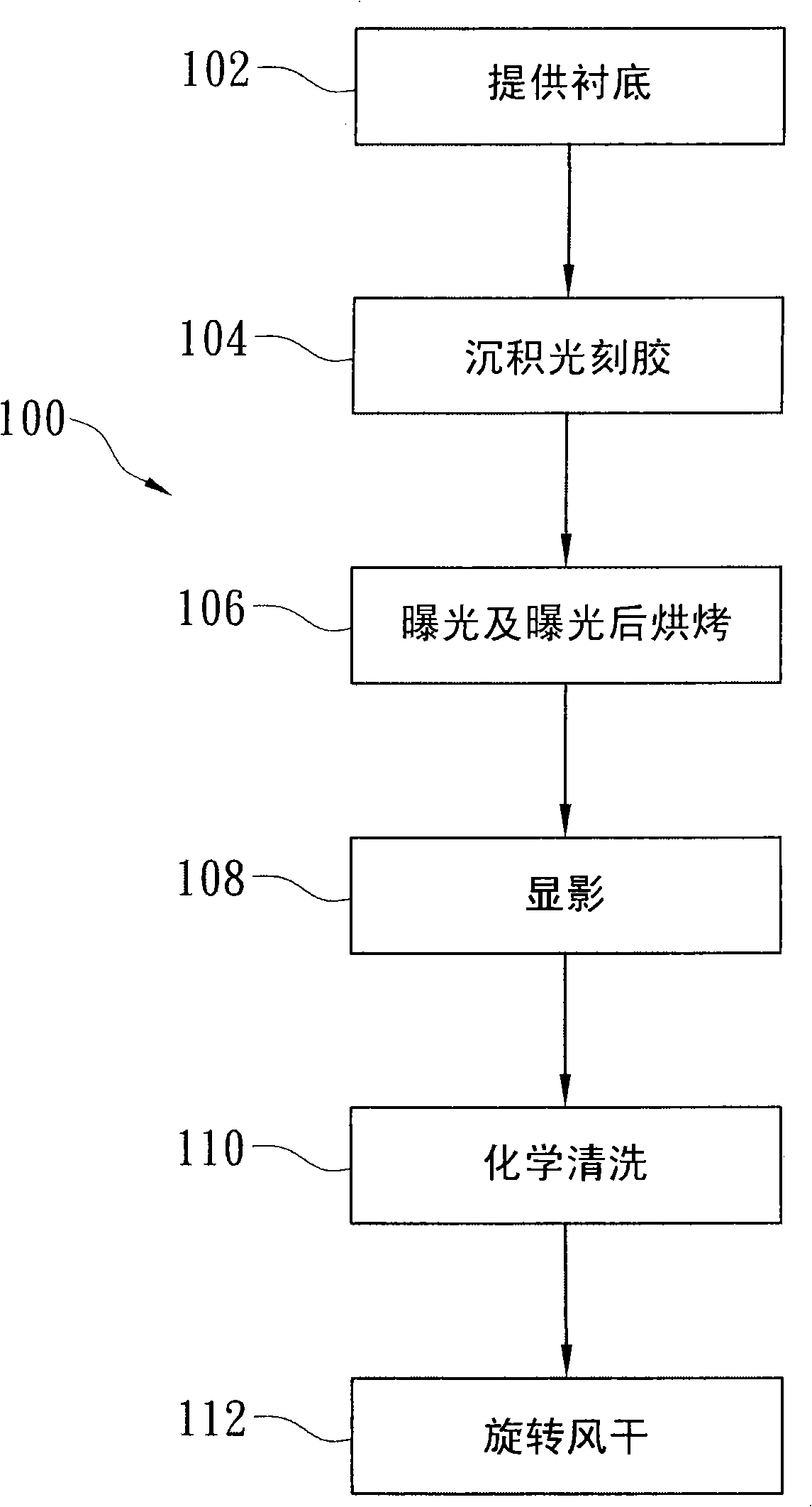

[0028] figure 1 A flowchart of a photolithography process method 100 according to an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com