Pneumatic gas heating device and gas heating method

A gas heating device, a pneumatic technology, which is applied to the heating device and the generation of other non-combustion heat, etc., can solve the problems such as none, and achieve the effects of uniform heating, fast heating speed and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

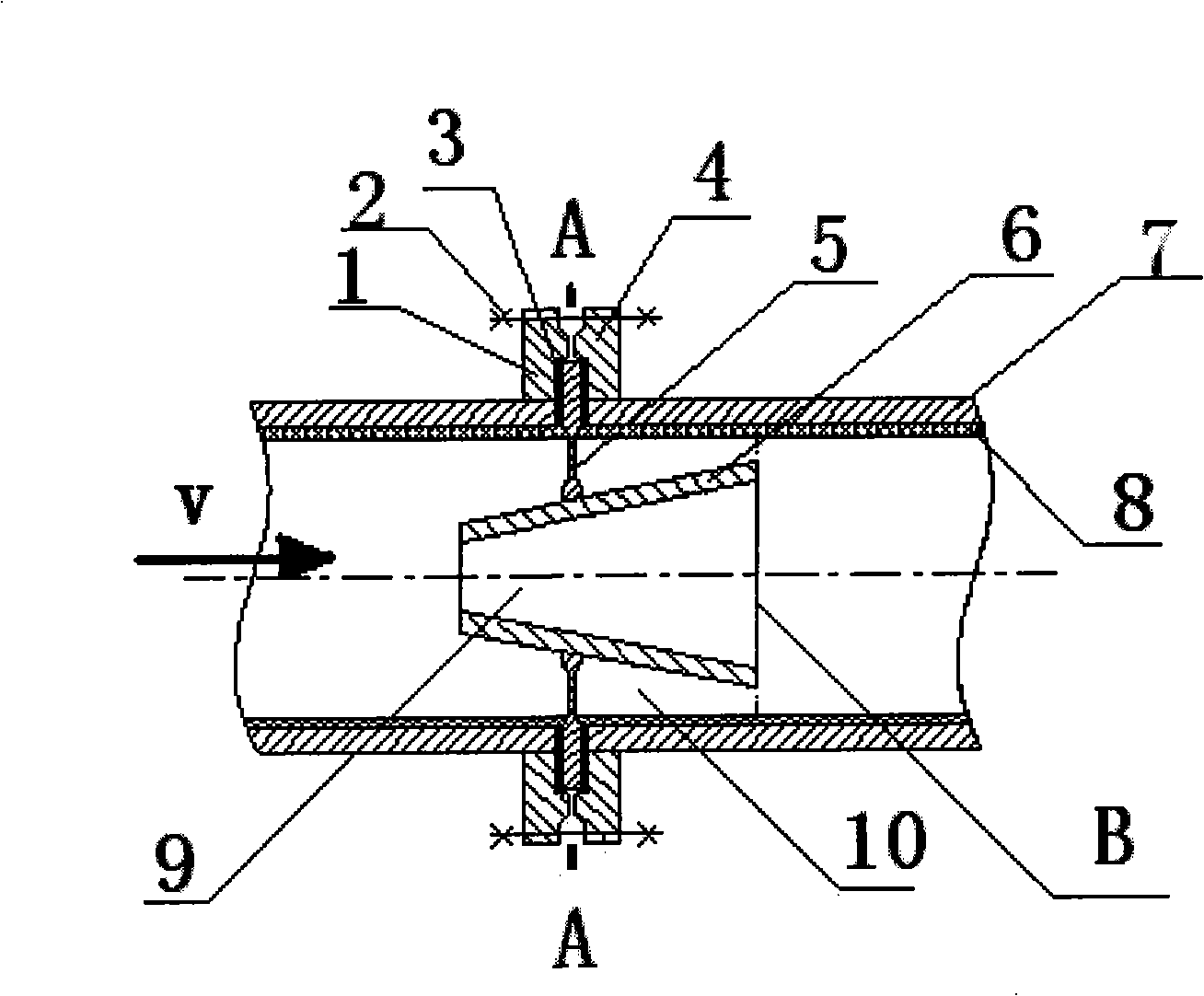

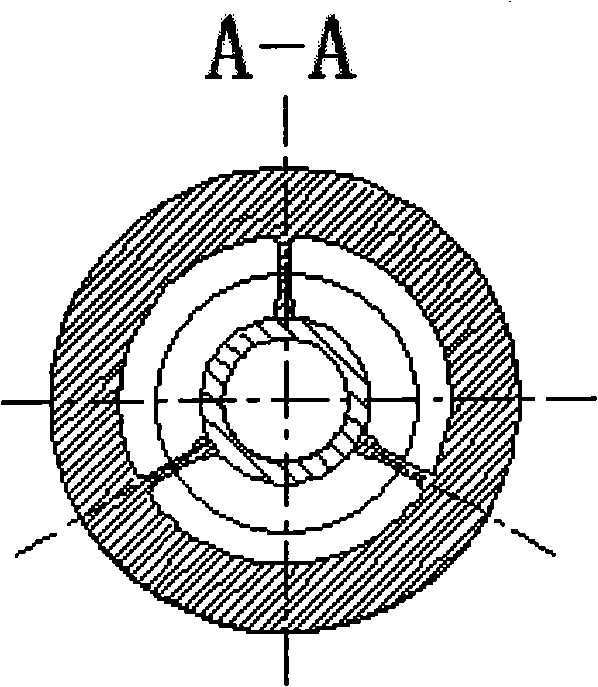

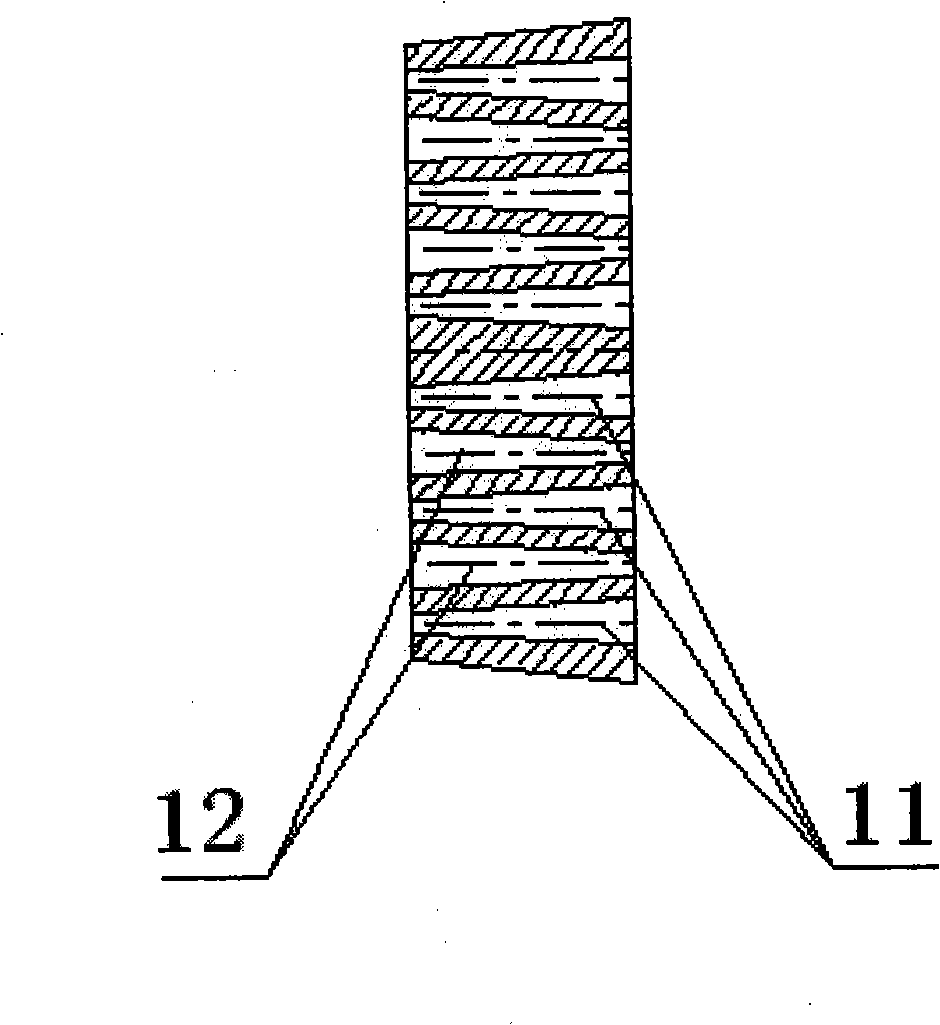

[0018] Such as figure 1 , figure 2 As shown, a pneumatic gas heating device includes a pipe 7 that is sealed and connected to each other by two straight pipes. The inner wall of the pipe is provided with a heat insulating layer 8, and a support member 5 is provided at the joint of the two straight pipes to connect a pipe 7 The nozzle 6 at the center of the inner section forms an annular channel 10 that tapers in the positive direction and expands in the opposite direction between the nozzle and the pipeline insulation layer 8; the nozzle 6 is provided with a variable cross-section air flow channel 9 . The sealing connection of the two sections of straight pipes adopts connecting flanges 1 and 4, connecting bolts 2 and sealing washers 3. The structure of the supporting member 5 is a flange with ribs divided into three equal parts in the radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com