High temperature resistant epoxide resin conductive adhesive

A technology of epoxy resin and conductive adhesive, which is applied in the field of conductive adhesive, can solve the problem of low heat resistance of conductive adhesive, improve electrical conductivity or thermal conductivity, improve heat resistance and high temperature stability, and improve high temperature performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the total weight of the high temperature-resistant epoxy resin conductive adhesive is 10g, and its composition is calculated by weight fraction:

[0022] Modified epoxy resin 25 parts

[0023] Silicone coupling agent 0.2 parts

[0024] 1 part of imidazole curing agent

[0025] Micron silver powder 70 parts

[0026] Nano silver particles 5 parts

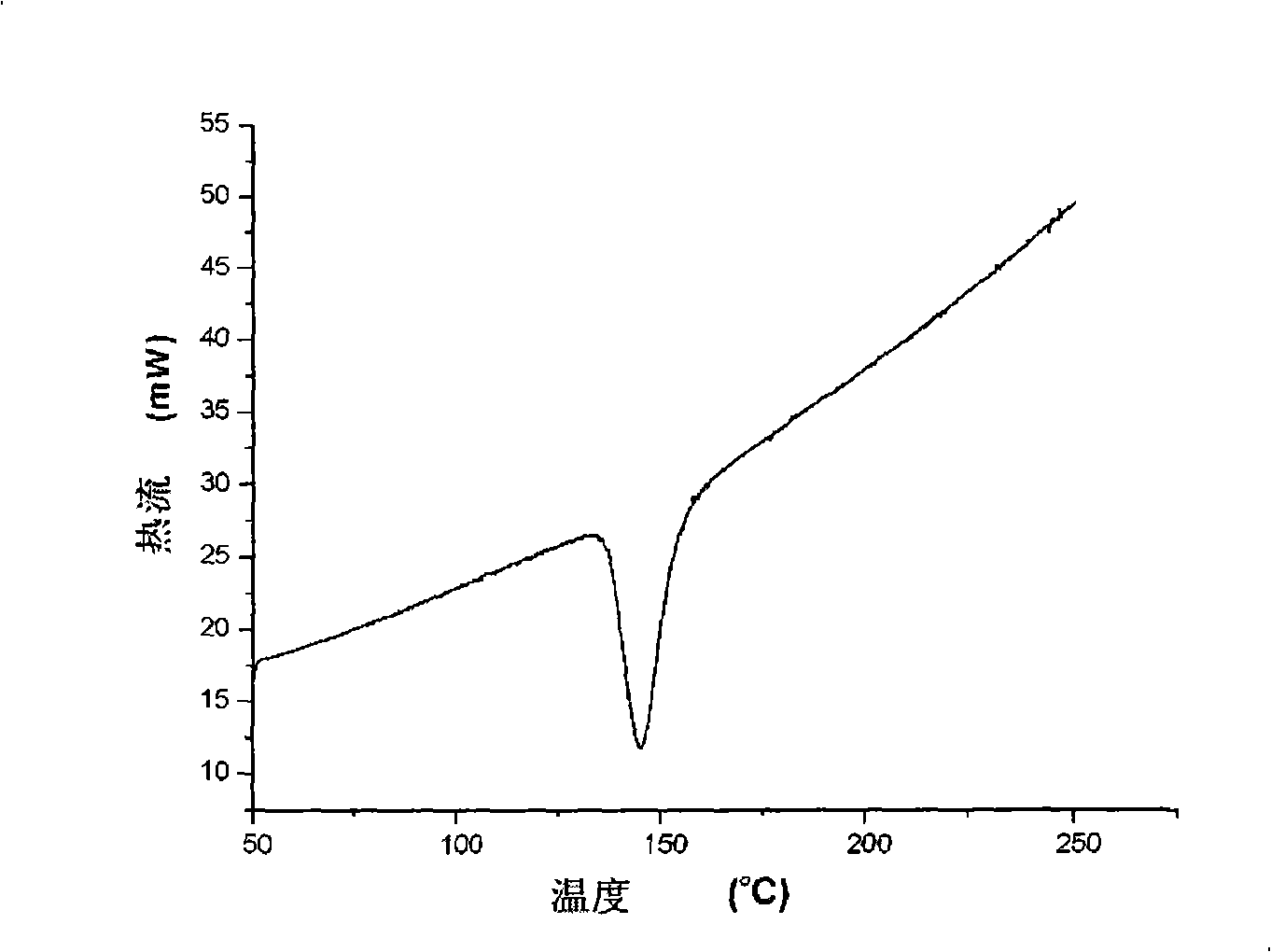

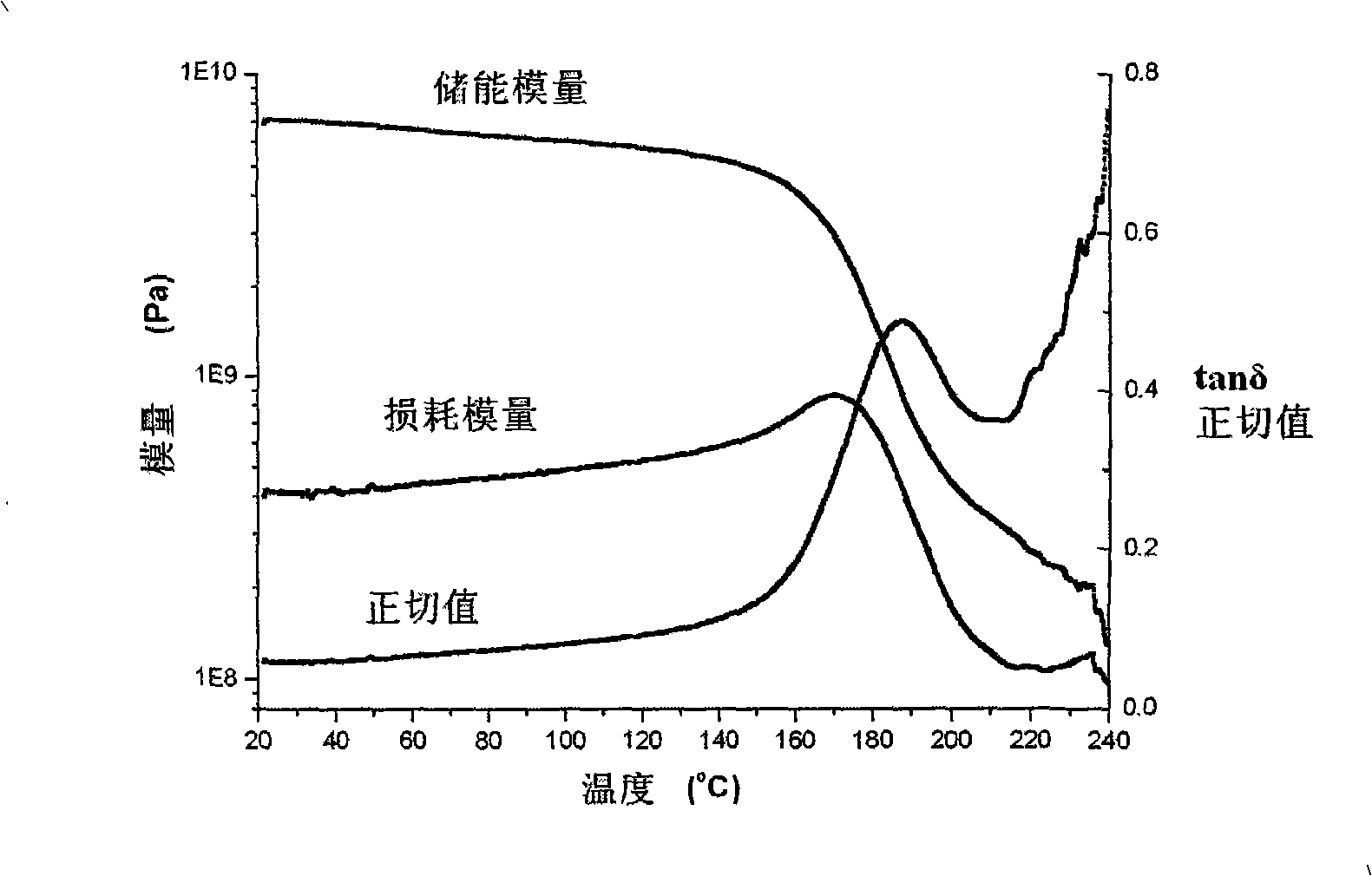

[0027] Mix the above well, then cure at 150°C for 30 minutes. The measured Tg is 200°C and the resistivity is 4×10 -5 Oh cm.

Embodiment 2

[0029] In this embodiment, the total weight of the high temperature-resistant epoxy resin conductive adhesive is 10g, and its composition is calculated by weight fraction:

[0030] Modified epoxy resin 25 parts

[0031] Silicone coupling agent 0.3 parts

[0032] 1.5 parts of imidazole curing agent

[0033] Micron silver powder 75 parts

[0034] Nano silver particles 5 parts

[0035] Carbon nanotubes 2.5 parts

[0036] The cross-sectional diameter of the carbon nanotubes is 30 nanometers, the above is mixed evenly, and then cured at 150° C. for 30 minutes. The conductive adhesive meeting the requirements of the present invention can be obtained.

Embodiment 3

[0038] In this embodiment, the total weight of the high temperature-resistant epoxy resin conductive adhesive is 10g, and its composition is calculated by weight fraction:

[0039] Modified epoxy resin 20 parts

[0040] Silicone coupling agent 0.15 parts

[0041] 1 part of imidazole curing agent

[0042] Micron silver powder 60 parts

[0043] Nano silver particles 3 parts

[0044] Carbon nanotubes 3 parts

[0045] The cross-sectional diameter of the carbon nanotubes is 30 nanometers, the above is mixed evenly, and then cured at 150° C. for 30 minutes. The conductive adhesive meeting the requirements of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com