Preparation of heat-insulating energy-saving mortar containing phase-change material

A phase-change material and mortar technology, which is applied in the field of preparation of thermal insulation and energy-saving mortar, can solve problems affecting wall thermal insulation and energy conservation, liquid phase-change material seepage, and house dampness, etc., so as to improve thermal insulation and energy saving effects, and increase crack resistance and anti-seepage Performance, the effect of preventing shedding and water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In every cubic meter of mortar: pottery sand 200kg, phase change material content in pottery sand holes is 15.0% (weight ratio), phase change material is a blend of methyl stearate / n-dodecyl alcohol, compounding ratio 1: 1. Polypropylene hollow fiber 1.5kg, the phase change material content in the fiber cavity is 17.5% (weight ratio), and the phase change material is methyl stearate; Cement 250kg; Vitrified microspheres 125kg; Water-cement ratio 0.5; Stir The time is 3 minutes; it is used for wall painting, the thickness is 2.0cm, the measured bond strength is 0.67MPa, and the heat transfer coefficient is 1.20W / (m 2 · K).

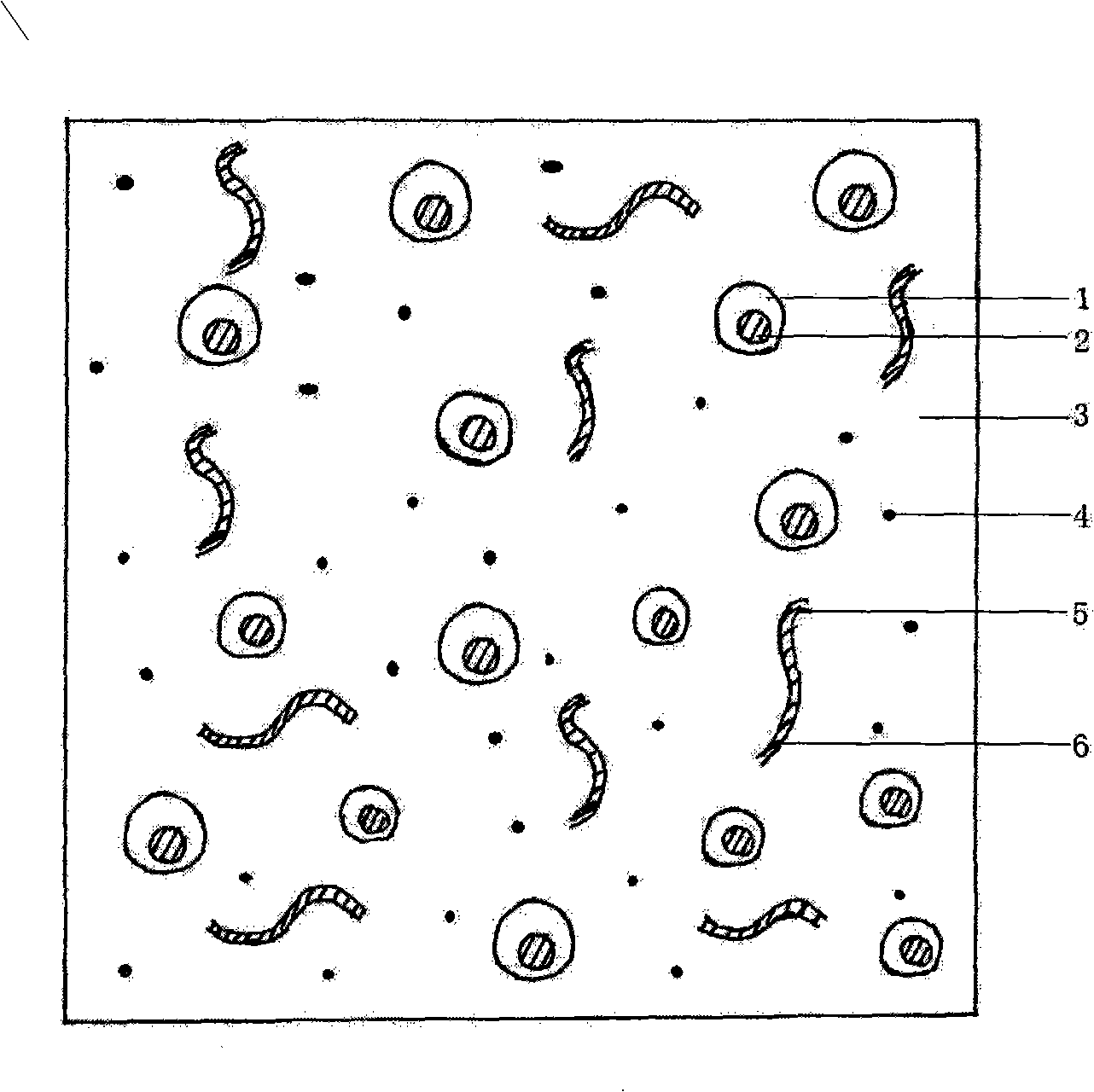

[0025] Ingredients from the set of the invention figure 1 It can be seen that 1. pottery sand, 2. phase change material in pottery sand holes, 3. cement, 4. inorganic vitrified microbeads, 5. polypropylene hollow fiber, 6. polypropylene hollow fiber cavity phase change material.

Embodiment 2

[0027] Per cubic meter of mortar: pottery sand 350kg, phase change material content in pottery sand holes is 17.5% (weight ratio), phase change material is a blend of capric acid / lauric acid, compounding ratio 1:1; polypropylene hollow Fiber 1.6kg, phase-change material content is 15.0% (weight ratio) in the fiber cavity, and phase-change material is methyl stearate; Cement 200kg; Vitrified microsphere 150kg; Water-cement ratio 0.55; Stirring time 3.5 minutes; Painted on the wall, the thickness is 3.0cm, the measured bond strength is 0.8MPa, and the heat transfer coefficient is 1.02W / (m 2 · K).

Embodiment 3

[0029] In every cubic meter of mortar: pottery sand 400kg, the phase change material content in the pottery sand hole is 22.0% (weight ratio), phase change material is the blend of butyl stearate / paraffin, compounding ratio 1: 1.5; Propylene hollow fiber 1.8kg, the phase change material content in the fiber cavity is 20.5% (weight ratio), the phase change material is the blend of capric acid / lauric acid, compound ratio 1: 1; Cement 150kg; Vitrified microbead 180kg; water-cement ratio 0.6; stirring time 4 minutes; used for wall painting, thickness 3.0cm, measured bond strength is 0.72MPa, heat transfer coefficient is 1.05W / (m 2 · K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com