Cooperative controller for two-motor vector control frequency control system and construction method thereof

A technology of coordinated controller and vector control, applied in vector control systems, control systems, motor generator control, etc. Performance Anti-load disturbance running performance, excellent coordinated control, excellent effect of speed and tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

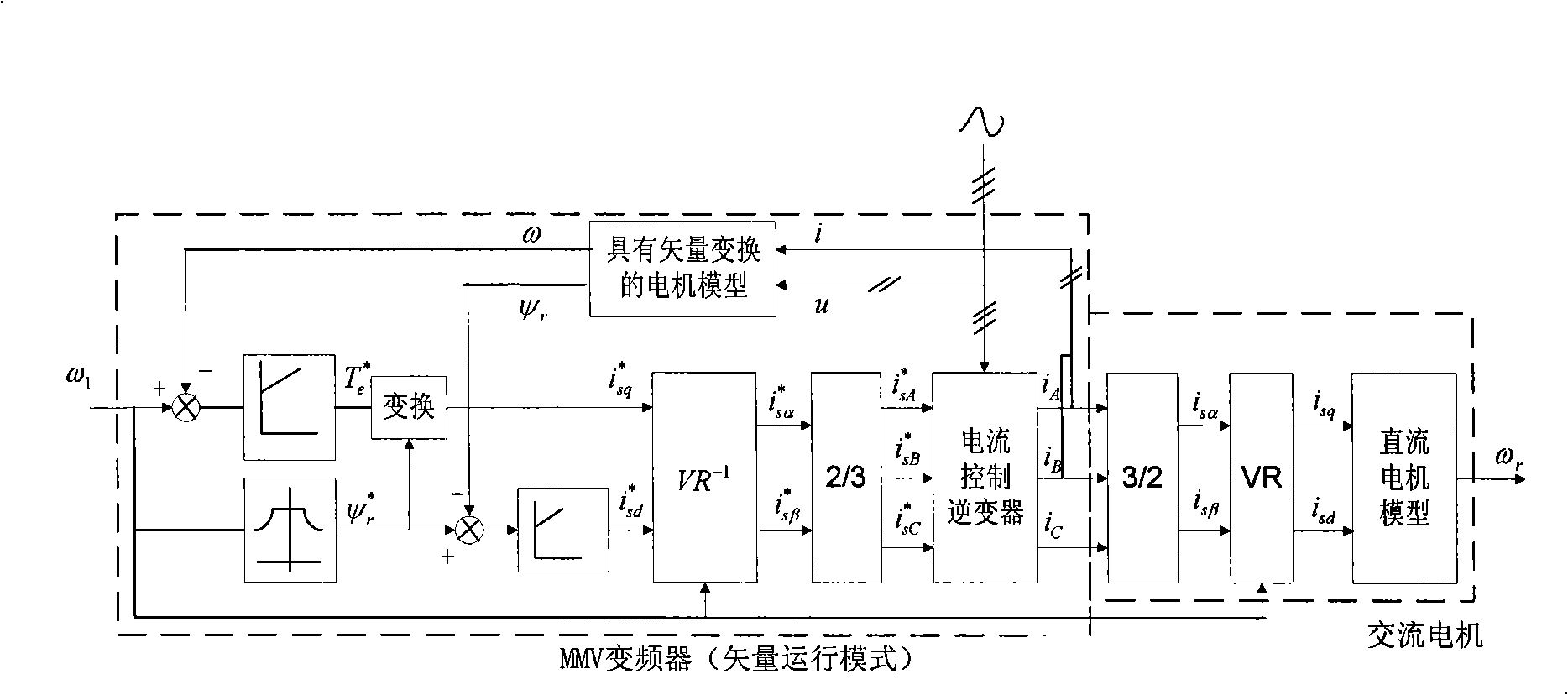

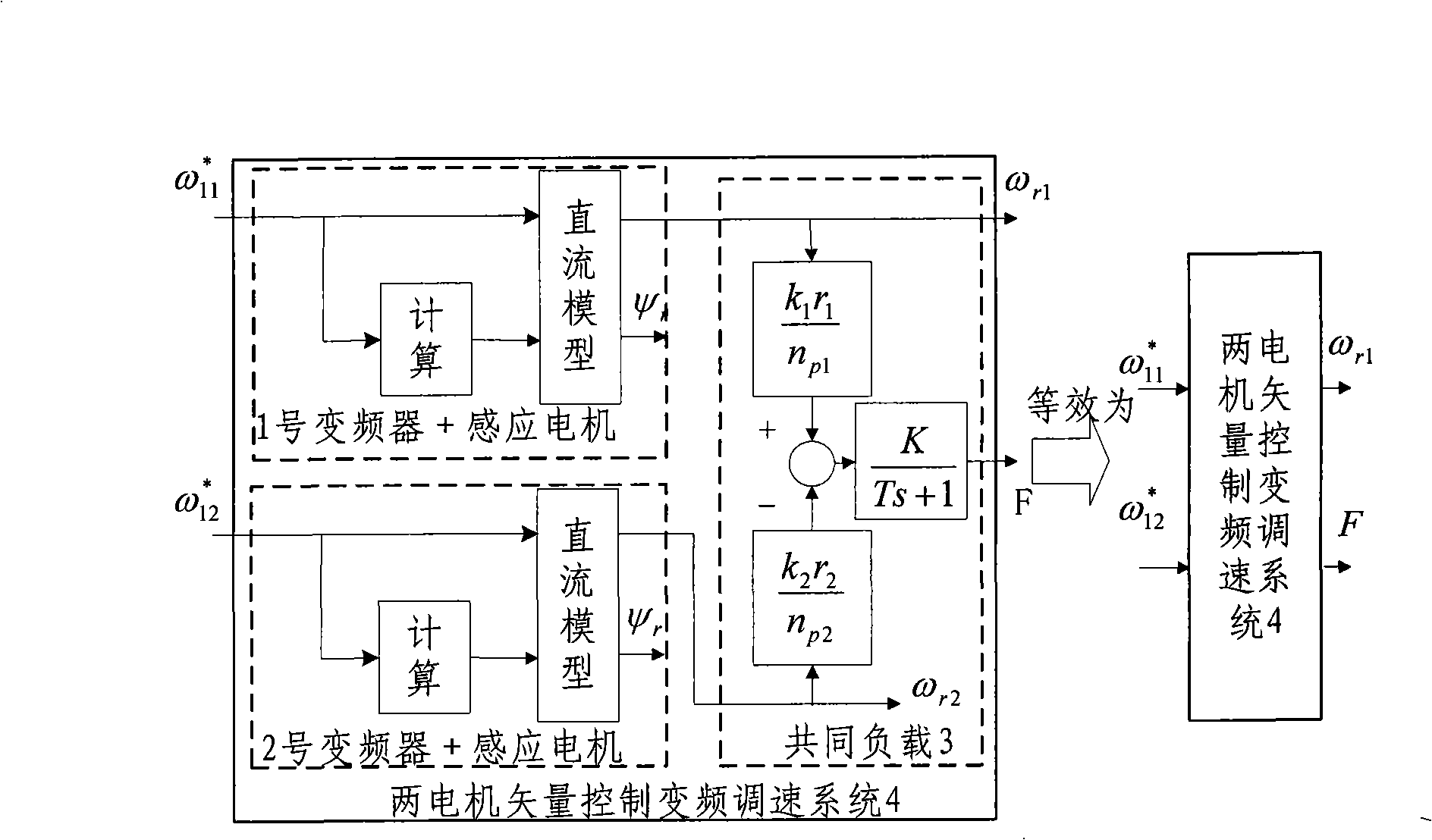

[0020] The solution of the present invention is to take two frequency converters 1, two induction motors 2 and a common load 3 working in a vector control mode as a whole to form a two-motor vector control frequency conversion speed regulation system 4 . According to the analysis, it can be seen that the mathematical model of the two-motor vector control frequency conversion speed regulation system 4 is a third-order differential equation under the static two-phase coordinate system, the two outputs are speed and tension respectively, the relative order of speed is first order, and the relative order of tension is the first order. The relative order is the second order, and the overall system, that is, the inverse system corresponding to the two-motor vector control frequency conversion speed regulation system 4 exists. A static artificial neural network with 5 input nodes and 2 output nodes (such as multi-layer network MLN or meridional basis function network RBF, etc.) is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com