Method for directly preparing vitamin C with sodium gulonate

A technology of sodium guronate and vitamins, which is applied in the field of ascorbic acid preparation, can solve the problems of poor removal of impurities such as miscellaneous acids, influence on industrialization prospects, and huge equipment, and achieve remarkable energy saving and emission reduction effects, good industrial development prospects, and low energy consumption. Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] ① Preparation of 2KGA-Na crystals: 2-keto-L-sodium guronate (abbreviated as 2KGA-Na) ultrafiltrate obtained by two-step fermentation with a concentration of 8-10% (W / V). Low-temperature concentration, activated carbon decolorization, filtration, continuous crystallization, and centrifugation to obtain 2KGA-Na crystals with a purity ≥ 98%. Its process control points are as follows:

[0077] a. Cell solids removal rate: 100%

[0078] b. Soluble protein removal rate: 70% to 85%

[0079] c. Evaporation and concentration temperature: 50~65℃

[0080] d. Continuous crystallization temperature: 20~30℃

[0081] e. The ratio of 2KGA-Na in the mother liquor recovered by electrodialysis: more than 80%.

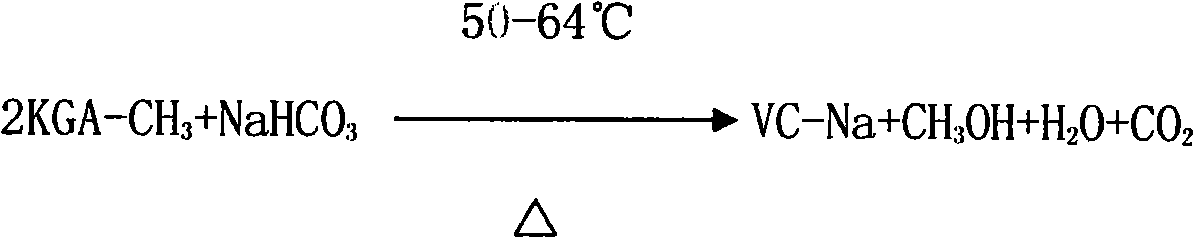

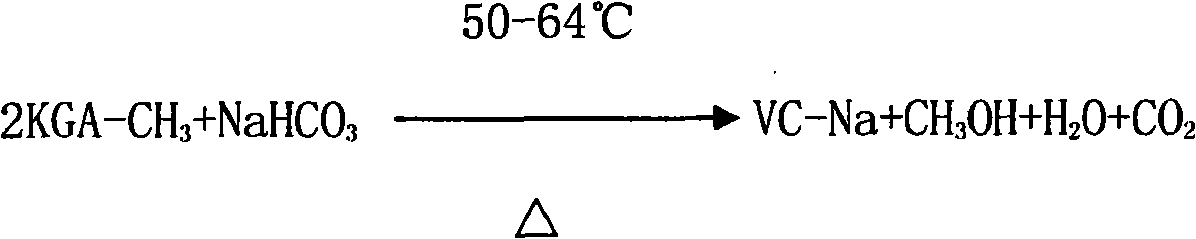

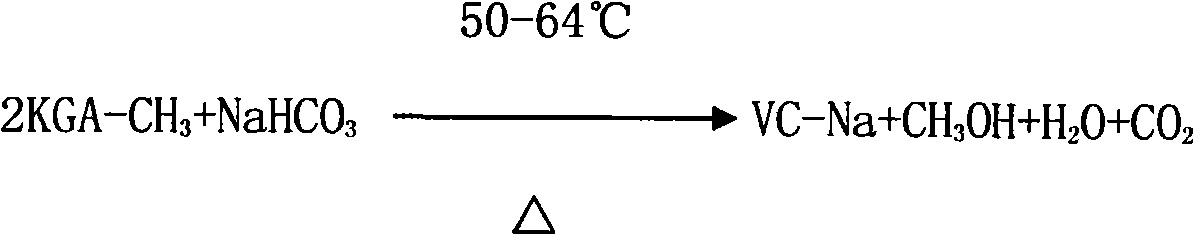

[0082] ② Methyl esterification reaction: put 2KGA-Na crystals and sulfuric acid catalyst into anhydrous methanol in turn, heat up after adding the materials, and start the reaction after the temperature reaches the reaction temperature. After 0.5 to 1.5 hours of reaction, filte...

Embodiment

[0123] 1. Preparation of 2KGA-Na crystals

[0124] Take 2.5L of the fermented mash with the above content, and remove 100% of the bacteria and more than 70% of the soluble protein through ultrafiltration with a molecular weight cut-off of 10,000 to 30,000 Daltons. The concentration factor is 10 times, and the retentate is washed with an equal volume of water Filtration and dehydration, the total concentration of the final filter cake reaches 20 times.

[0125] 2.625L permeate was evaporated and concentrated, added charcoal, filtered, evaporated and cooled to 28°C for crystallization to produce 2KGA-Na crystals, and 80% of the 2KGA-Na was recovered from the mother liquor by electrodialysis, and then incorporated into 2KGA-Na concentrated crystals to obtain the final product 216 g of 2KGA-Na crystals with a purity of 98% were obtained. 2KGA-Na total yield ≥ 96%.

[0126] 2. Methyl esterification reaction:

[0127] Get content and be 216g of 2KGA-Na crystals of 98.15%, be plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com