High-capacity electrode active material for secondary battery

A technology of electrode active materials and metals, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of being unable to be used as electrode active materials for lithium secondary batteries, and insufficient to provide cycle life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

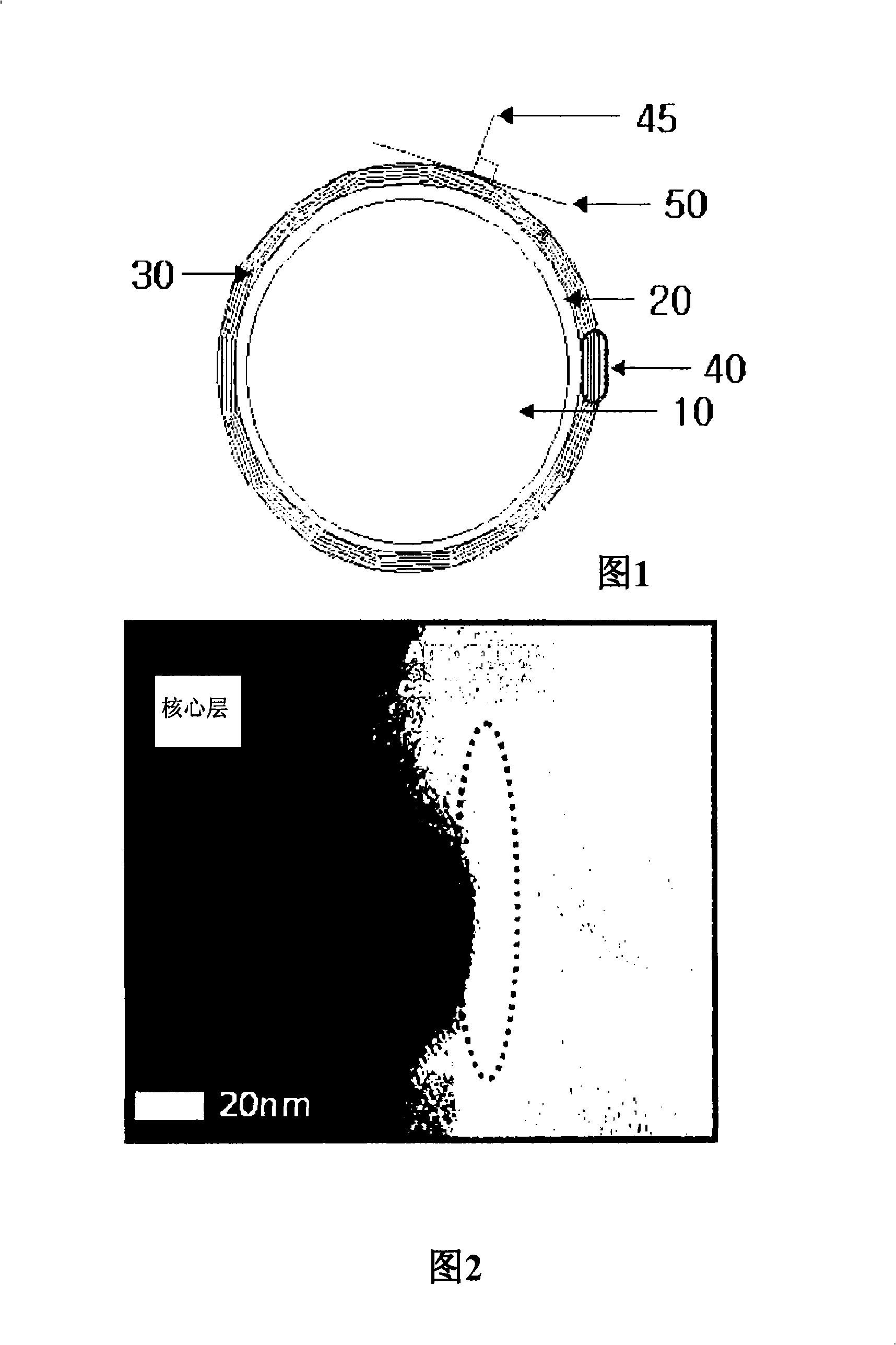

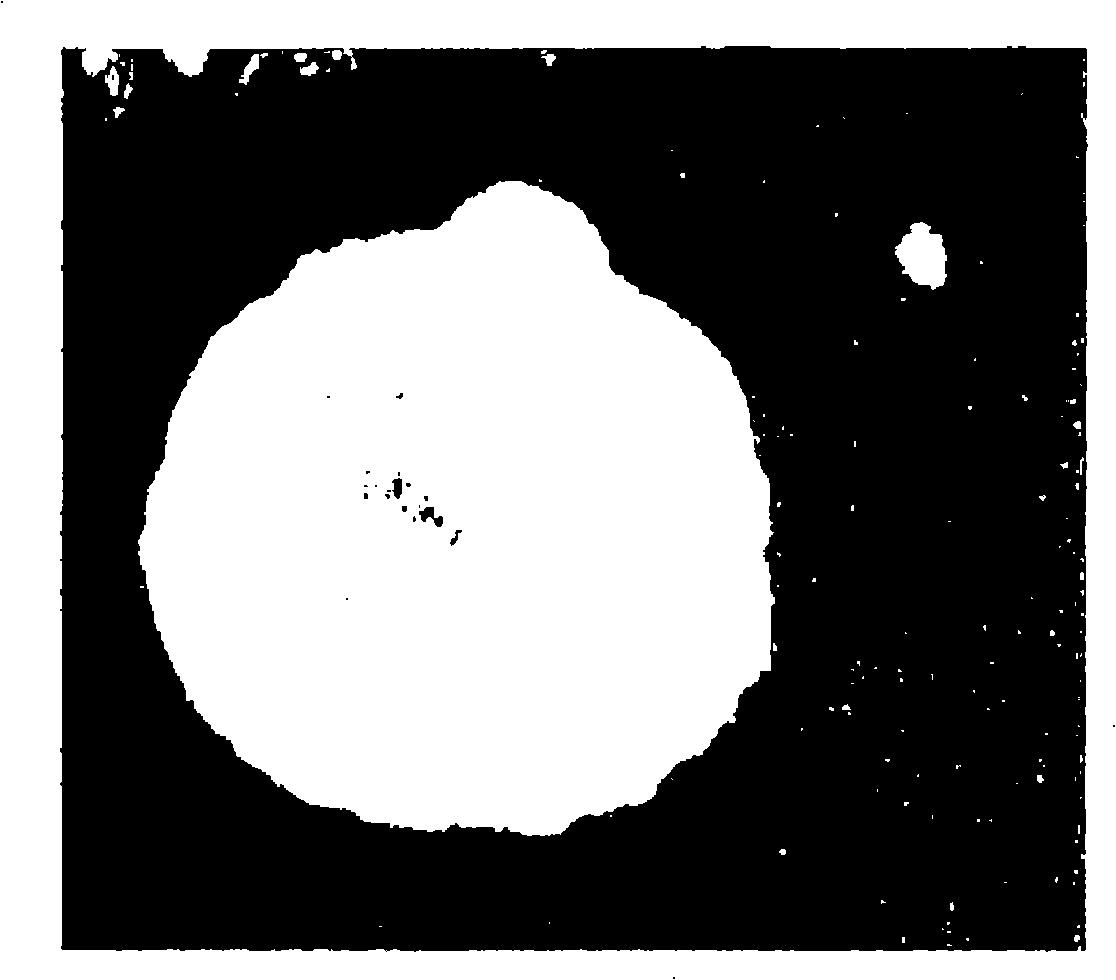

[0053] Silicon was mixed with natural graphite at a ratio of 50 parts by weight: 50 parts by weight to provide a mixture, and stainless steel balls with a diameter of 3 mm and the mixture were placed in a mechanical fusion system from Hosokawa Micron Corporation at a ratio of 5:1 by weight. Next, the obtained mixture was subjected to mechanical alloying at a compressive stress / shear stress ratio of 0.5 and a rotational speed of 600 rpm for 30 minutes to provide the electrode active material of the present invention. Fig. 2 is a photo of the electrode active material taken by TEM. It can be seen from FIG. 2 that the electrode active material includes a core layer, an amorphous carbon layer and a crystalline carbon layer, and the arrangement of the crystalline carbon layer is parallel to the tangential direction of the core layer.

[0054] Then, 100 parts by weight of the electrode active material powder obtained above, 10 parts by weight of PVDF as a binder, and 10 parts by wei...

Embodiment 2

[0058] A battery was provided in the same manner as in Example 1, except that silicon and natural graphite were mixed at a ratio of 50 parts by weight: 50 parts by weight to provide a mixture, and spherical zirconia with a diameter of 5 mm was mixed with the mixture at a ratio of 10:1 by weight. Placed in a mechanofusion system obtained from Hosokawa Micron, the resulting mixture was then subjected to mechanical alloying at a compressive stress / shear stress ratio of 0.5 and a rotational speed of 600 rpm for thirty minutes to provide an electrode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com