Two-stage reaction method for mixed butylene hydroformylation

A butene hydroformylation reaction technology, applied in the field of two-stage hydroformylation reaction to prepare valeraldehyde, can solve problems such as inability to meet high efficiency, reaction differences, etc., and achieves reduction in production cost, improvement in conversion rate, and simplification of process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

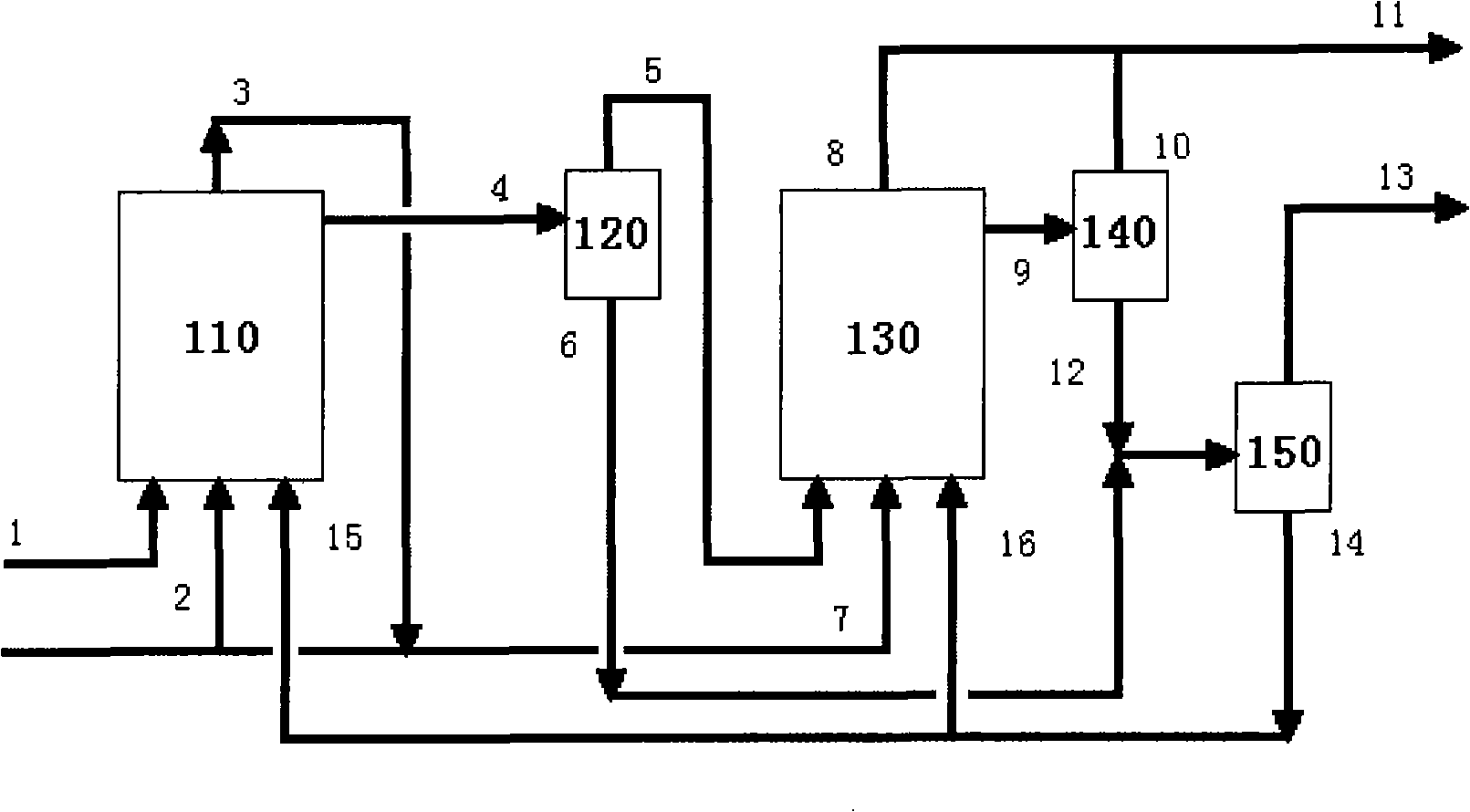

[0072] This example uses Figure 4 To illustrate.

[0073] Mixed butene 1 composed of 1-butene 50%, 2-butene 36%, butane 14%, and isobutene<1% was synthesized with the synthesis from the stripping column 154 at a rate of 680 g / h Gas 2 enters the first reactor 101 respectively, and in a catalyst solution composed of rhodium-bisphosphite catalyst and valeraldehyde and valeraldehyde trimer solvent, hydrogen formaldehyde is carried out under the conditions of 85°C and 2.1MPa Acylation reaction. The rhodium concentration of the catalyst is 200ppm, and the molar ratio of phosphorus to rhodium is 5:1. The first gaseous phase flow 3 is drawn from the top of the reactor, which mainly contains unutilized synthesis gas and some raw material components. This stream passes through the condenser 112, so that the condensable components taken out are condensed and returned to the reactor. , and the stream passes through a valve with a regulating function (not shown in the figure) so as to ...

Embodiment 2

[0086] According to the same operation steps as in Example 1, except that the mass ratio of the catalyst return stream 15 of the first reactor to the catalyst return stream 16 of the second reactor was adjusted to 30:70, the total utilization rate of raw material olefins was 85.44%.

Embodiment 3

[0088] According to the same operation steps as in Example 1, except that the mass ratio of the catalyst return stream 15 of the first reactor to the catalyst return stream 16 of the second reactor was adjusted to 70:30, the total utilization rate of raw material olefins was 86.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com