Flash memory and preparation method thereof

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as insufficient isolation, and achieve the effect of preventing short-circuit channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

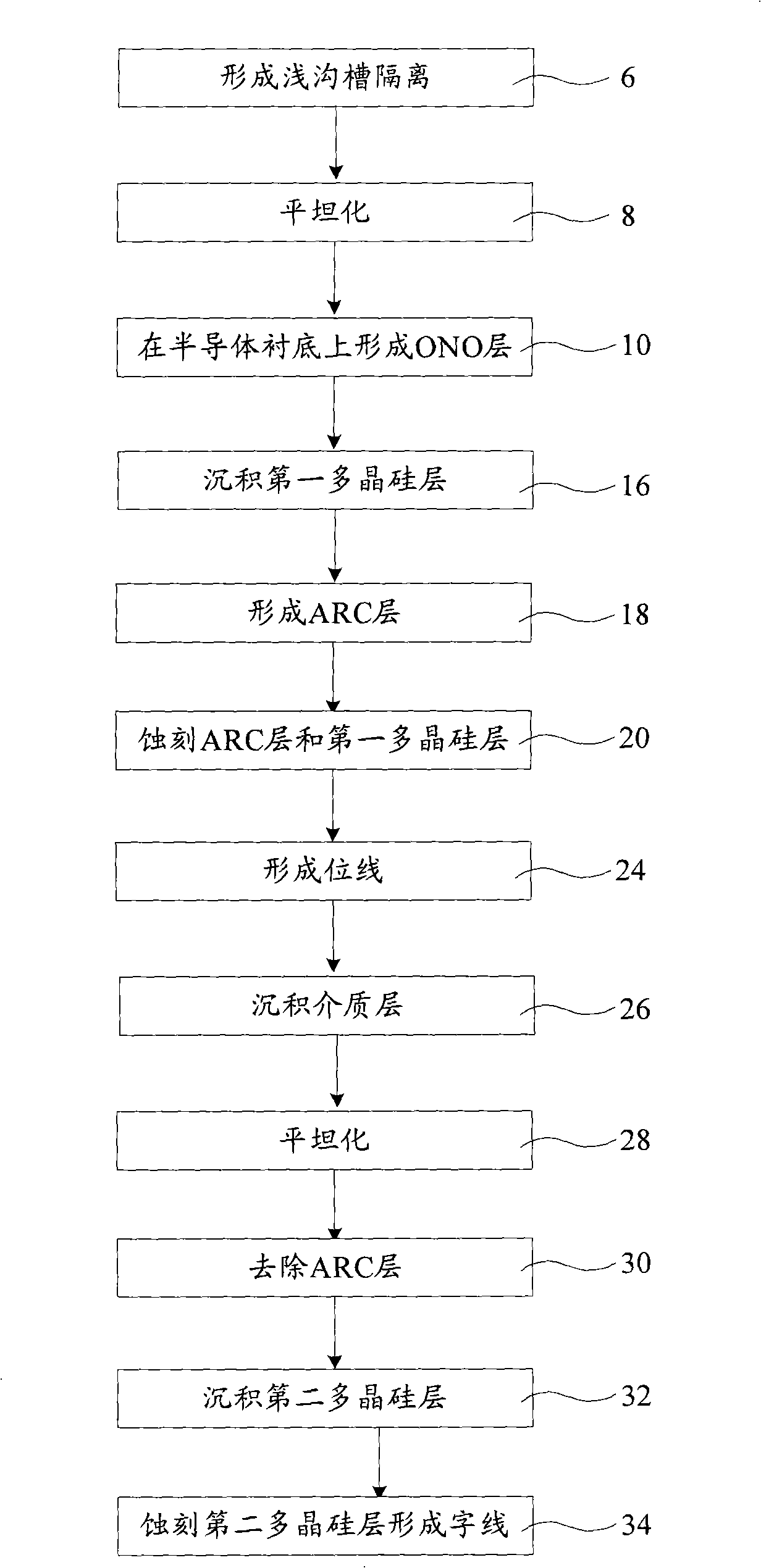

[0026] The present invention provides a flash memory and a manufacturing method thereof. In this embodiment, in the manufacturing process of the SONOS flash memory, the three-layer stack structure of the medium layer-trapping charge layer-dielectric layer of the SONOS flash memory is reserved in the area other than the word line And form sidewalls on both sides of the word line, fully between the word line and the word line, between the bit line and the bit line, between the word line and the bit line, around the shallow trench isolation and between the word line and the semiconductor substrate Isolation is carried out to prevent the formation of short-circuit channels and cause leakage current.

[0027]The present invention firstly provides a method for manufacturing a SONOS flash memory, comprising: providing a semiconductor substrate, on which there is a three-layer stacked structure consisting of a dielectric layer-charge-trapping layer-dielectric layer, a first polysilicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com