Semiconductor integrated circuit and layout method for the same

A technology of integrated circuits and semiconductors, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc. It can solve the problems of large chip clock skew, large wiring resistance, and inability to calculate high-precision delays. Achieve the effect of small clock offset and low power consumption

Inactive Publication Date: 2008-10-22

PANASONIC CORP

View PDF3 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the comb-type clock wiring can control the deviation of the wiring delay so that the circuit does not malfunction to prevent a decrease in operating speed, but if the flip-flops on the output side and the receiving side of the signal are one-to-one, it can be controlled The deviation of wiring delay, but in general circuits, due to the many-to-many relationship, it is very difficult to control the deviation of all flip-flops to wiring delay

In addition, although the herringbone clock is effective when the chip size is small, in a large-scale semiconductor integrated circuit, the branch wiring in the horizontal direction is long, and the wiring resistance from the center to the end of the branch wiring is extremely high. Large, there is a problem that the clock skew between the center of the chip and the periphery of the chip increases due to the deviation of the wiring delay

In addition, since many clock synchronization units are connected to the clock backbone wiring as loads, there is also a problem that the variation in the wiring delay of the clock backbone wiring is also large.

In addition, in the mesh type clock, since the clock is wired in a grid pattern for the entire block, the wiring resistance is small, and the variation of wiring delay is small, but there is a problem that the total wiring length of the clock is long, and the load on the clock driving unit that supplies the clock signal Large capacity, large power consumption

In this case, if there is a clock skew before multiple clock driving units, the through current will flow between the clock driving units through the herringbone clock wiring and mesh wiring, and there is a problem that the power consumption will increase.

In addition, in the delay calculation tool currently available on the market at the standard cell level, when one clock line is driven by multiple clock drive units like this, there is a problem that the delay calculation cannot be performed with high precision. Cannot account for the effects of crosstalk with other signal routing

In addition, in order to reduce the wiring delay of the clock signal, if the upper layer wiring with a thick film thickness and low resistance is used, it is necessary to use a wide wiring due to the limitation of the manufacturing process. Contact) is large, and if it is used for the entire clock wiring, the signal wiring area is insufficient, so it becomes difficult to use the upper layer wiring at the end side of the clock tree that drives many clock driving units or clock synchronization units

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

no. 2 approach

no. 3 approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

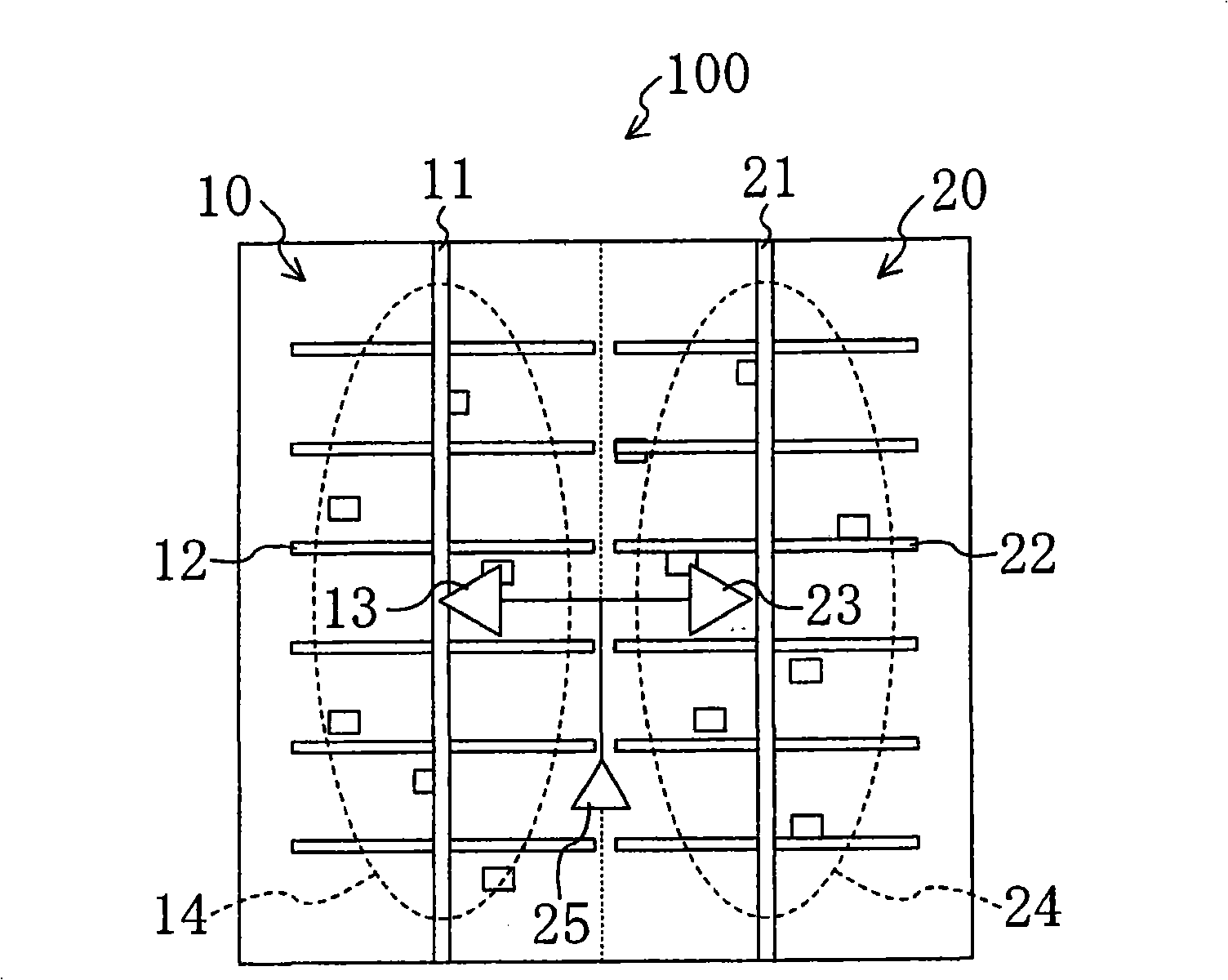

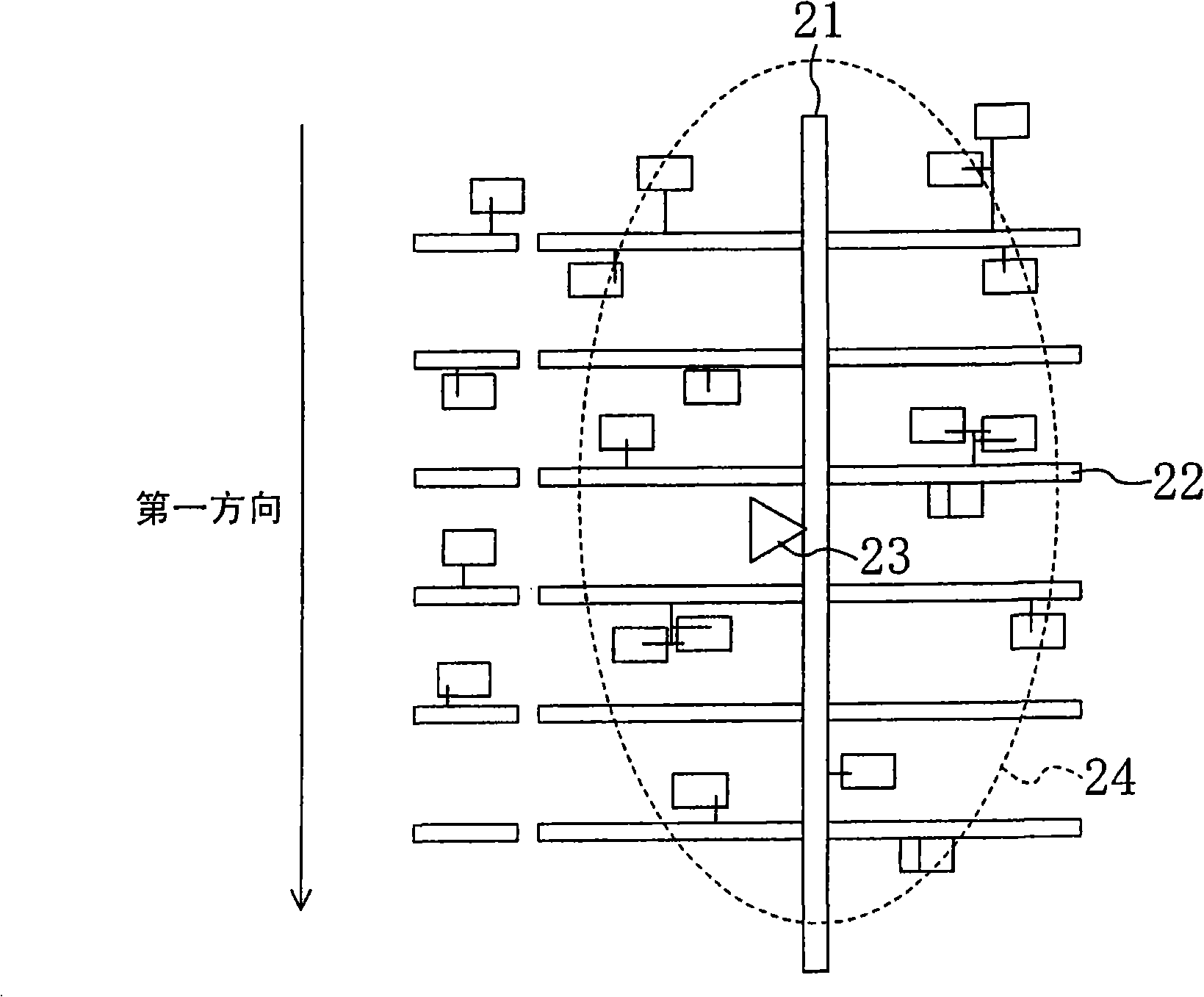

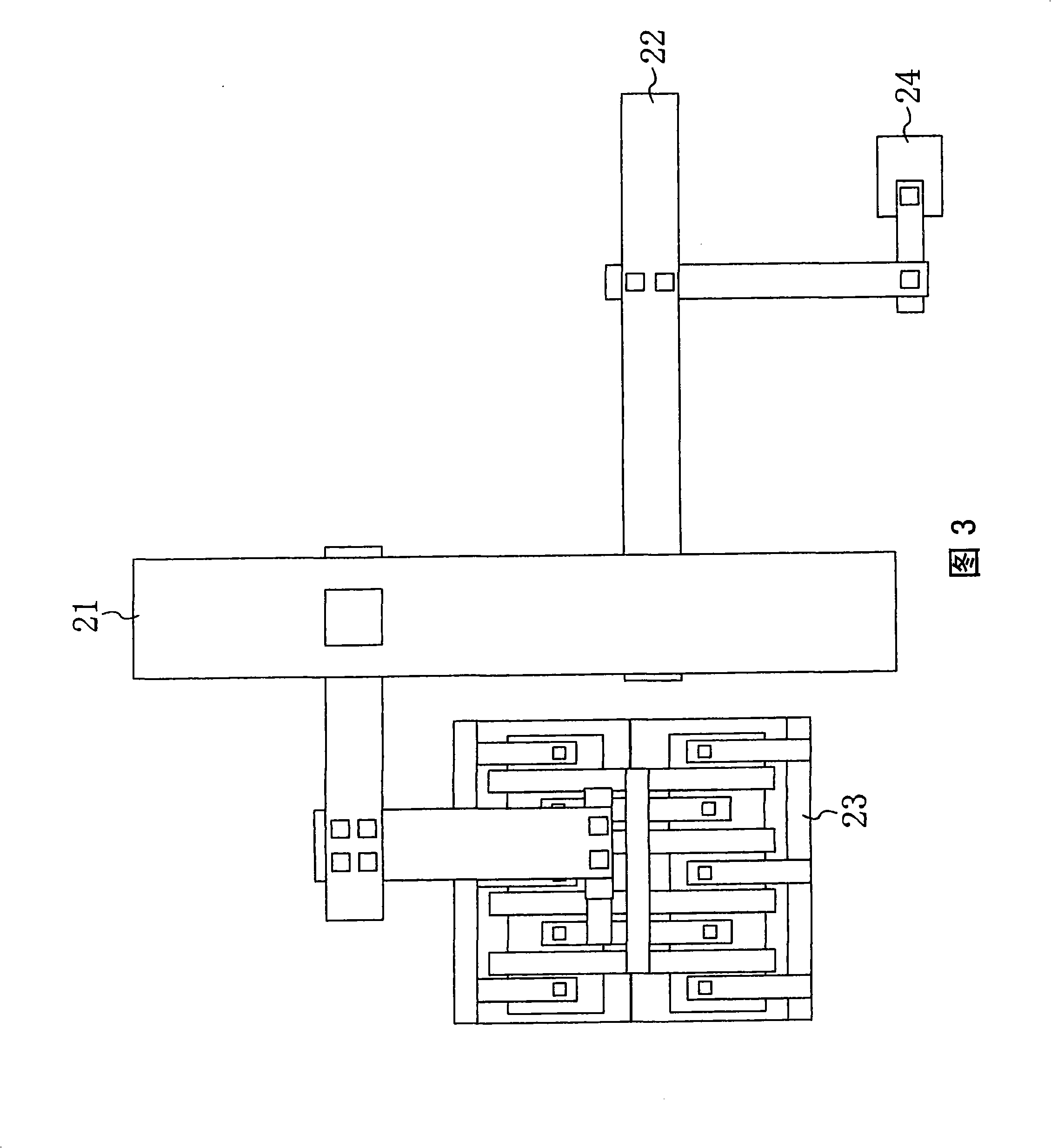

A functional block is divided into a plurality of regions. In each region, a clock main line extending along a first direction, a clock branch line group including a plurality of clock branch lines extending along a second direction perpendicular to the first direction and electrically connected to the clock main line, a clock driving cell electrically connected to the clock main line and a clock synchronous cell group including a plurality of clock synchronous cells electrically connected to the clock main line or the clock branch line group are provided. The clock branch line groups of the respective regions are electrically separated from each other, and the clock driving cell singly drives the clock main line connected thereto and the clock branch line group connected to the clock main line.

Description

Semiconductor integrated circuit and layout method of semiconductor integrated circuit technical field The present invention relates to a semiconductor integrated circuit using a clock distribution circuit for distributing clock signals in functional blocks constituted by standard cells, and a layout method of the semiconductor integrated circuit. Background technique In recent years, along with the increase in speed and function of digital circuits, the increase in speed and integration of semiconductor integrated circuits has been progressing. As the speed of semiconductor integrated circuits increases, it becomes important to suppress variation in signal delay (clock skew) of a clock signal that synchronizes flip-flops in the semiconductor integrated circuit. Clock skew refers to the difference in the arrival time of clock signals between synchronized flip-flops. If the clock skew is large, there is a problem that the operating frequency will decrease, which in turn wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50H01L27/02H01L23/528H01L21/82H01L21/768

Inventor 堤正范吉永生

Owner PANASONIC CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com