Double- modification method for advanced austenitic manganese steel

A modification treatment, austenitic manganese steel technology, applied in the field of modification treatment of austenitic manganese steel, can solve the problems of lack of control of pre-deposited austenite morphology, unstable rare earth modification effect, large cost increase, etc. Grain boundary distribution, weakening the possibility of microcracks, the effect of shortening the holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

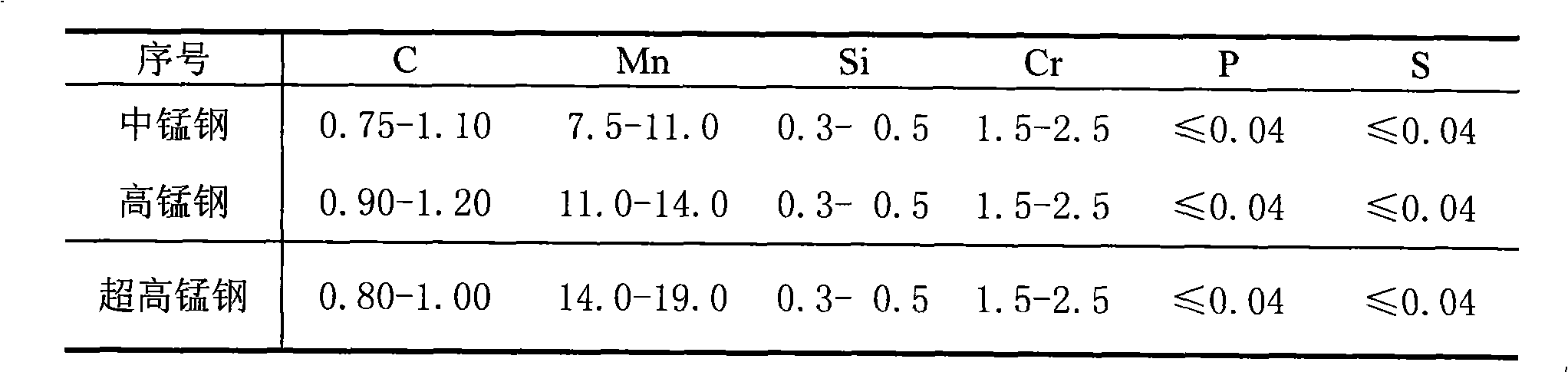

[0022] The basic composition (%) of the smelting target is shown in the table below:

[0023]

[0024] Taking the intermediate frequency furnace as an example, add the required raw materials into the furnace for smelting, after adding ferromanganese and silicon calcium to the molten pool for pre-deoxidation, add in the following order in the alloying stage: ferromanganese (ferromanganese nitride) → Rare earth alloy→V slag, wherein, the rare earth alloy adopts 1# Baotou rare earth ferrosilicon, and the added amount is 0.067-0.081% of the Re content of the molten steel weight; the added amount of the V slag is 2.0-2.5% of the molten steel weight.

[0025] Before tapping, 0.15% to 0.20% of the weight of the molten steel is used for final deoxidation, and the tapping temperature is 1500°C to 1550°C. When the steel is tapped, the surface is coated with a refractory material (Al 2 o 3 +corundum powder+water glass) nitrogen spray treatment agent device is inserted into the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com