Novel regeneration process for circulation oil of crude benzol device

A technology of recycling and recycling oil, applied in the coking field, can solve the problems of low efficiency of recycling oil regeneration system, inability to effectively remove degraded components of circulating oil, equipment blockage, etc., to improve the quality of circulating oil, increase efficiency, and reduce deterioration The effect of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

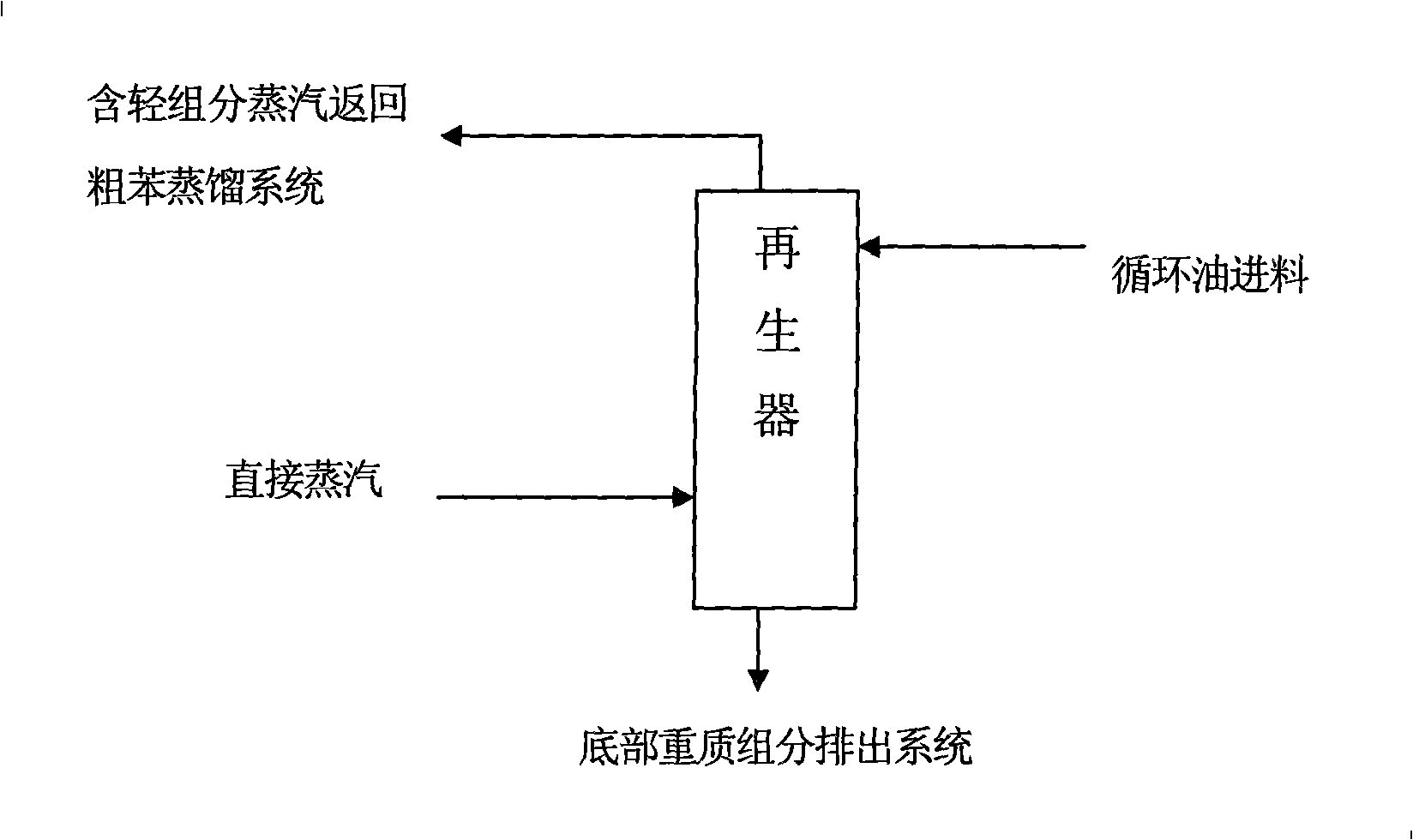

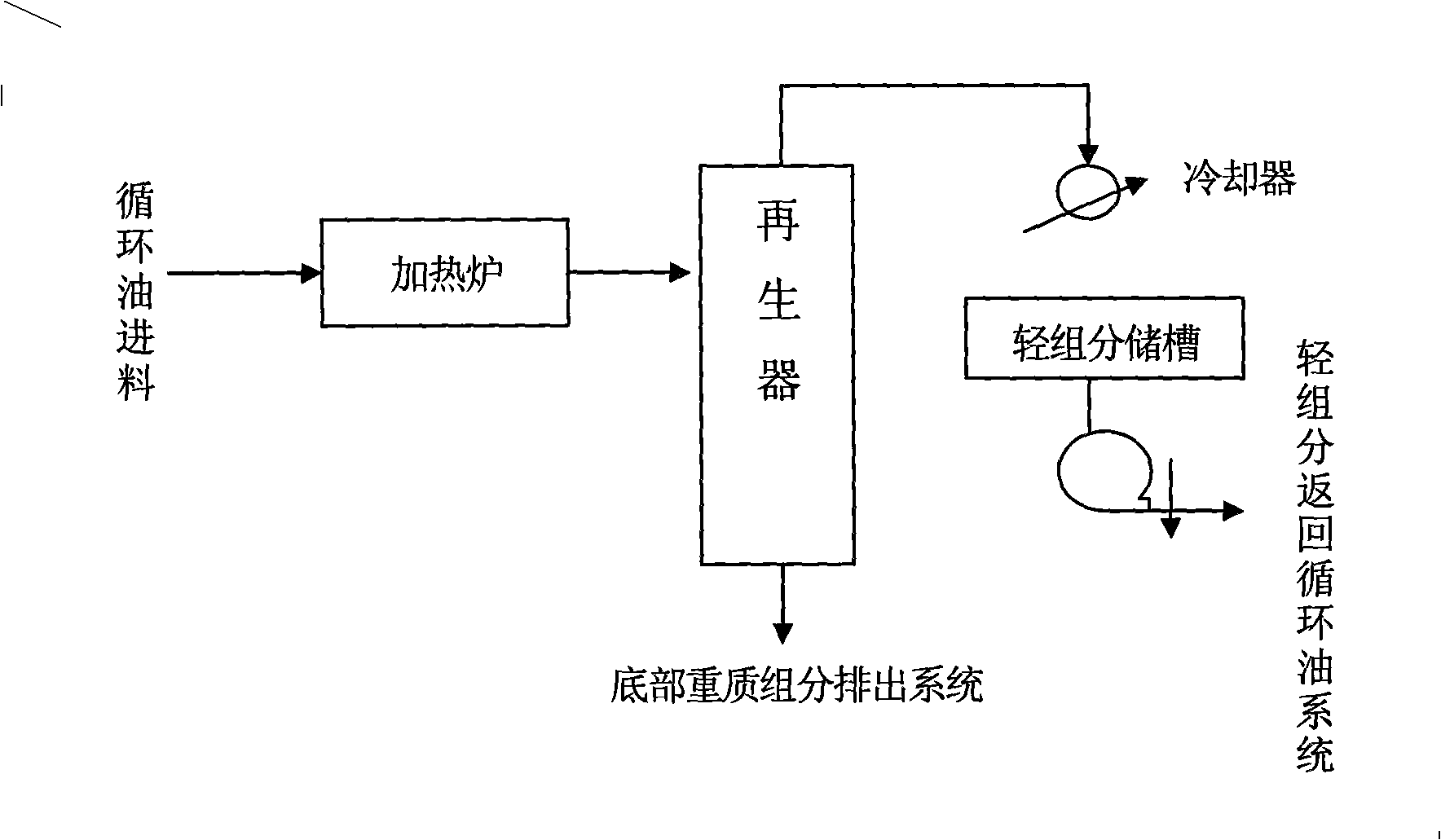

Method used

Image

Examples

Embodiment

[0021] Baosteel Co., Ltd. applied the new flash distillation regeneration method of the present invention to the actual operation of the circulating oil regeneration system of the crude benzene plant, and basically controlled the regenerated oil feed rate at 3t / h, which was about 100% of the system circulating oil circulation volume (180t / h). 1.7%, a heating furnace is added before the flash regenerator. The heat source of the heating furnace is coke oven gas. The feed temperature of the regenerated oil controlled at the outlet of the heating furnace is actually controlled at 250°C, 255°C and 265°C respectively. Judging from the operation and control process of nearly one month, the regeneration effect has been improved compared with the original direct steam distillation regeneration method. In Table 1 are the operating data for the flash distillation regeneration process described above.

[0022] Table 1 Operation data of flash distillation regeneration process

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com