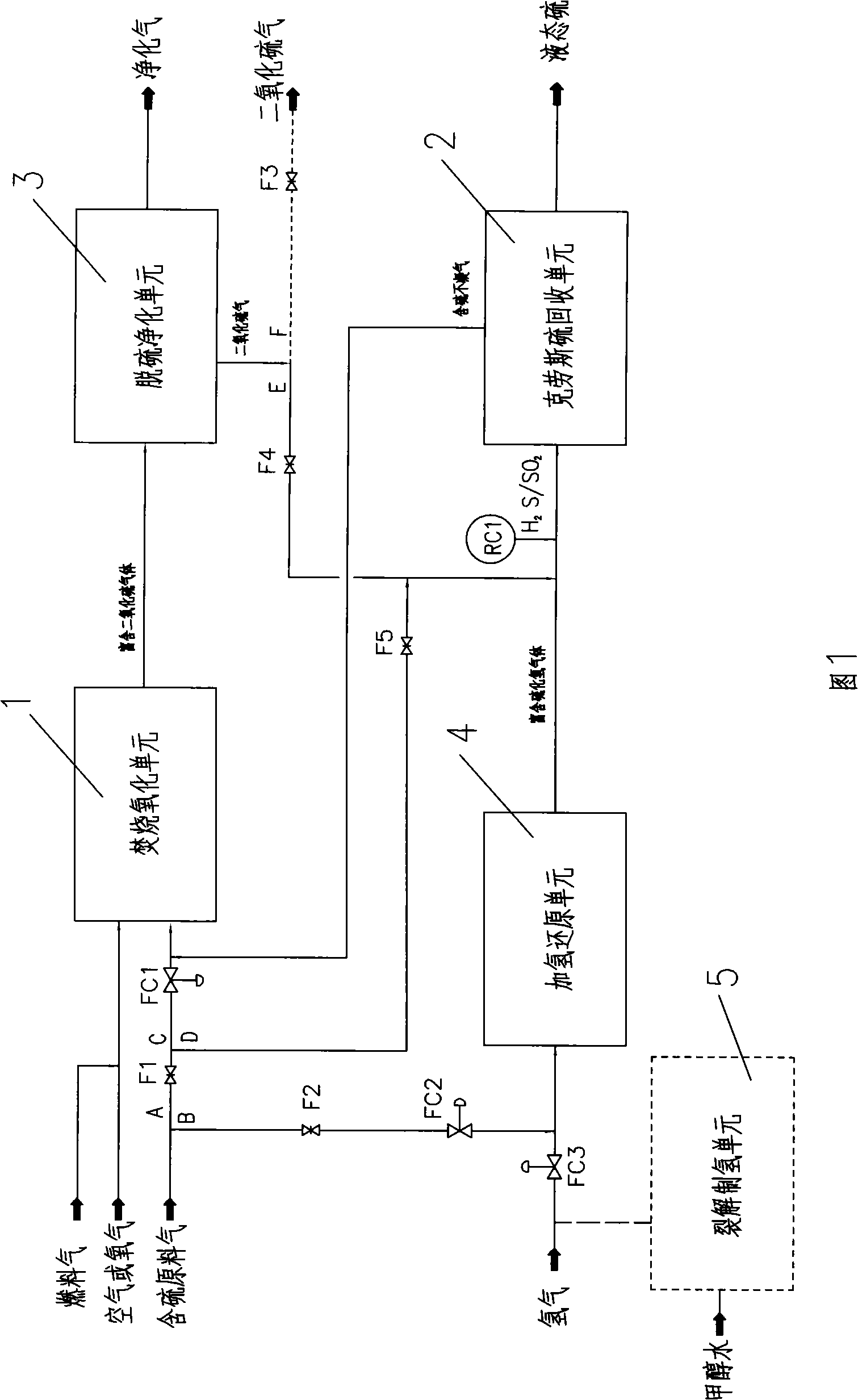

Oxidation, reduction and sulfur recovery multipurpose device

A technology of sulfur recovery and sulfur dioxide, which is applied in the direction of sulfur preparation/purification, etc., can solve the problems of existence, high total investment and operation cost of the device, and increase the difficulty of system control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The sulfur-containing feed gas of this example is rich in hydrogen sulfide, so there is no need to use the hydrogenation reduction unit (4), and the technological process of reclaiming sulfur is as follows:

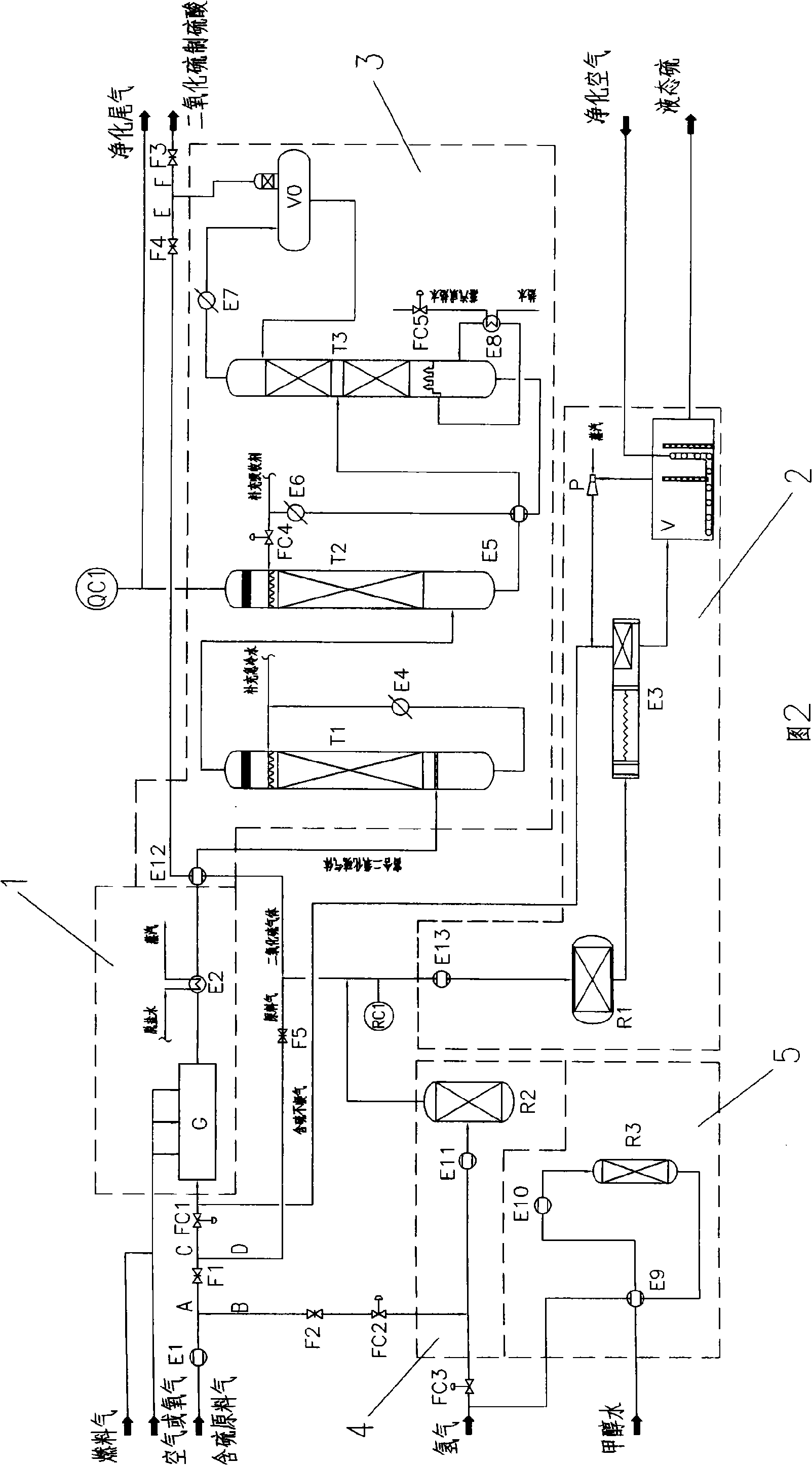

[0053] 1. See Figure 2, open the valves F1, F4, F5, close the valves F2 and F3, the sulfur-containing raw material gas is preheated by the preheater E1, and divided into two routes C and D through the valve F1, and the D route is connected with the desulfurization purification unit The sulfur dioxide gas from 3 is mixed and enters the Claus sulfur recovery unit 2 (hereinafter referred to as the sulfur recovery unit) through the preheater E13, and the C route is mixed with the sulfur-containing non-condensable gas returned from the sulfur recovery unit 2 and then enters the incineration and oxidation unit 1 , add excess air or oxygen to the incinerator G. If the concentration of hydrogen sulfide in the gas in the furnace is low, fuel gas can be added to support the c...

Embodiment 2

[0069] In this example, the raw material gas is rich in sulfur dioxide and other sulfide gases, and the content of hydrogen sulfide in it is relatively low, which is not enough to form the Claus reaction ratio relationship in which the molar ratio of hydrogen sulfide and sulfur dioxide is equal to 2. The sulfur dioxide is reduced to an appropriate amount of hydrogen sulfide, and the hydrogen sulfide is matched with the sulfur dioxide in the feed gas to meet the Claus reaction ratio relationship, so as to complete the sulfur recovery. The production process is as follows:

[0070] 1. Referring to Figure 2, close the valve F1, open the valves F2 and FC2, the sulfur dioxide-rich feed gas will all enter the hydrogenation reactor R2 after being preheated by the preheater E1 and heat exchanged by the heat exchanger E11, and at the same time, through the control adjustment The valve FC3 adds hydrogen in a limited amount, and the raw material gas and hydrogen undergo an incomplete hydr...

Embodiment 3

[0082] The feed gas in this example is a gas containing only sulfur dioxide and does not contain hydrogen sulfide. Therefore, the Claus reaction ratio relationship of hydrogen sulfide and sulfur dioxide molar ratio of 2 cannot be formed, and a part of the sulfur dioxide feed gas can be directly hydrogenated and reduced. An appropriate amount of hydrogen sulfide is formed, and the hydrogen sulfide is matched with another part of the sulfur dioxide raw material gas to meet the ratio relationship of Claus reaction, so as to complete the sulfur recovery. The specific production process is as follows:

[0083] 1. See Figure 2, close the valve F3 and the regulating valve FC1, open other valves, the feed gas is preheated by the preheater E1 and divided into two routes A and B, and the route A enters the route D through the valve F1 and directly goes to the heat exchanger E13 ; Route B enters hydrogenation reactor R2 through valve F2 and regulating valve FC2 mixed with hydrogen raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com