Method for increasing the efficiency of a combined gas/steam power station with integrated gasification combined cycle

A technology for fuel gasification and power plants, applied in steam engine installations, combined combustion mitigation, machines/engines, etc., to achieve the effect of reducing power and efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

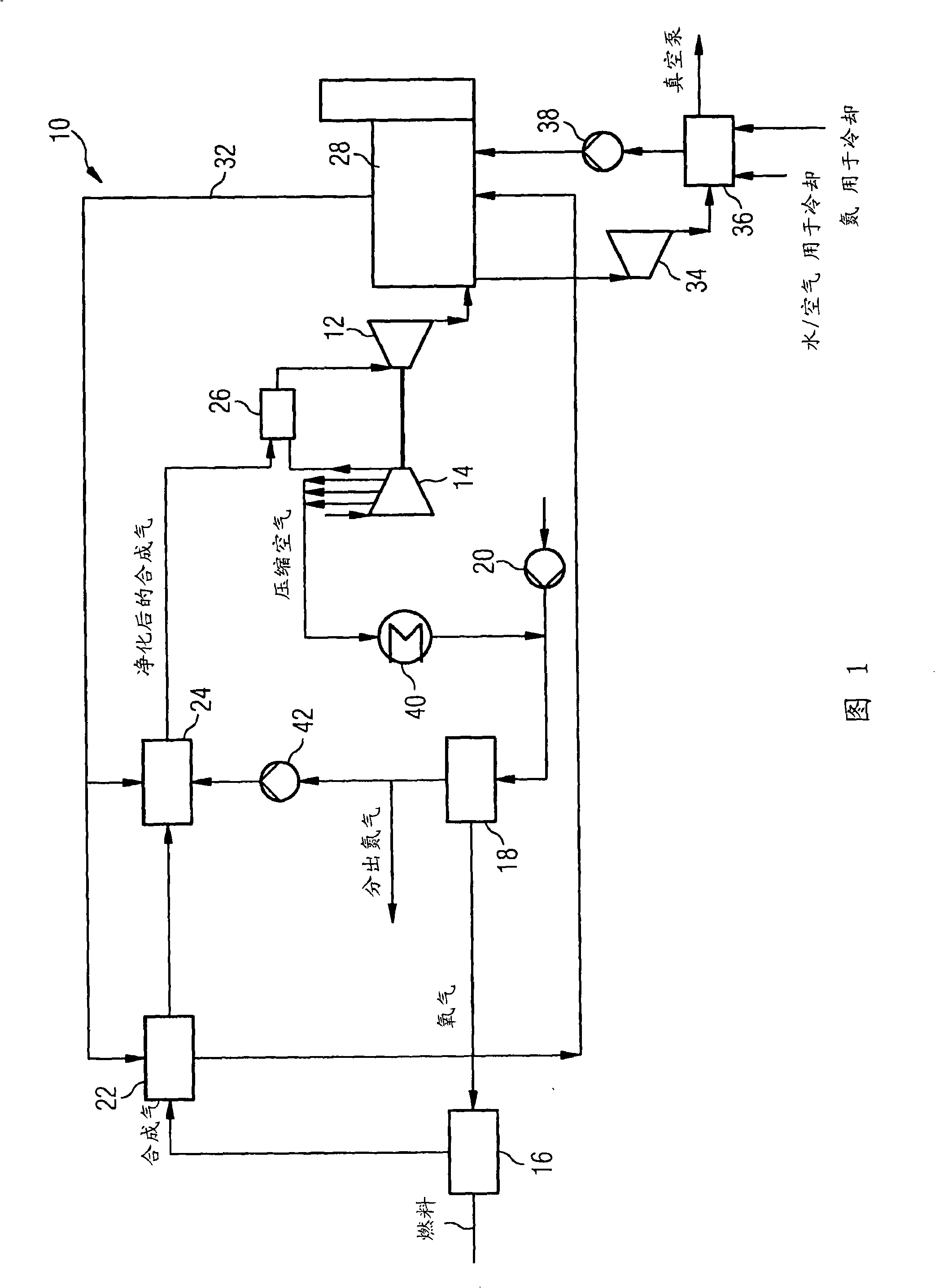

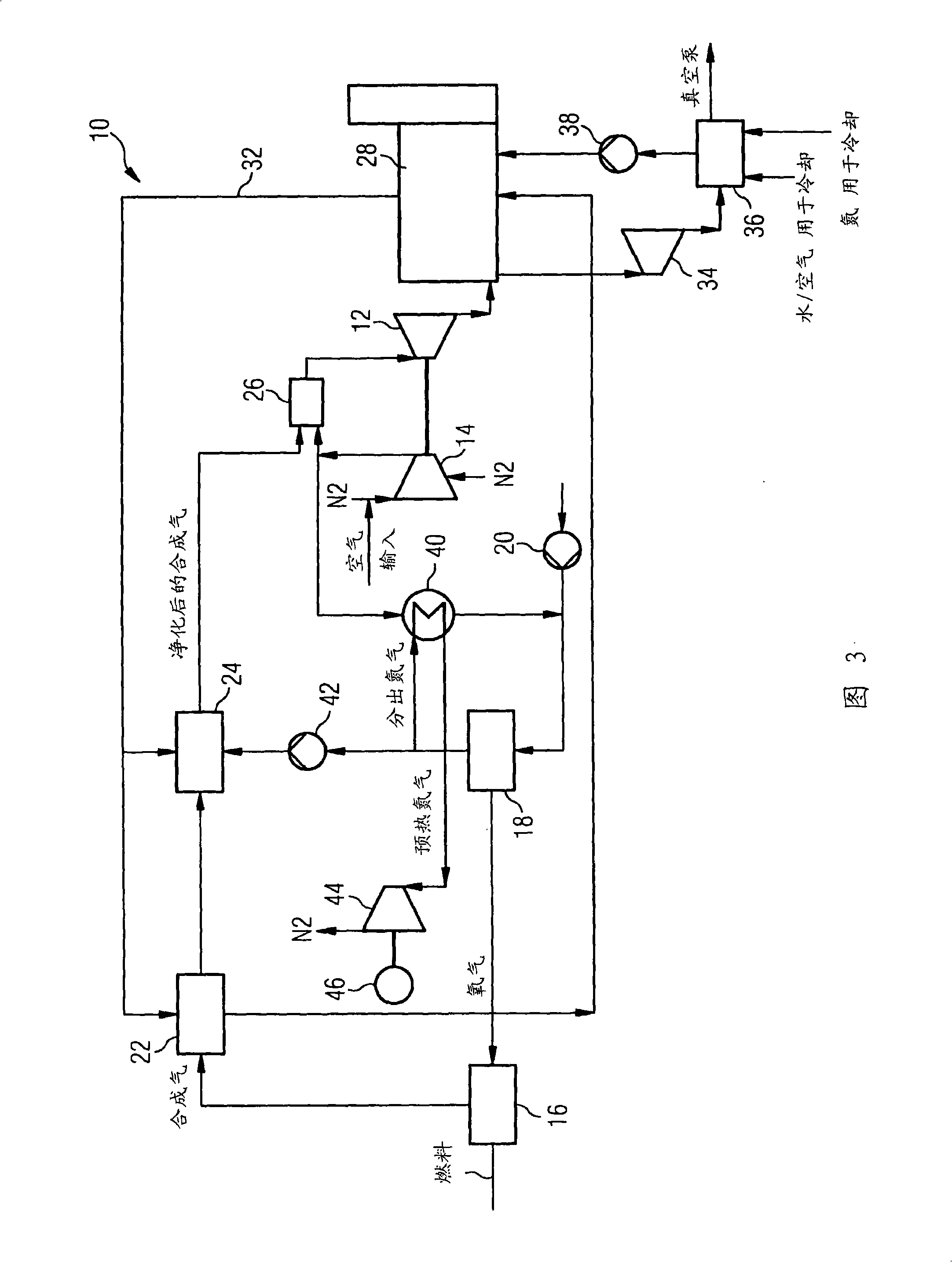

[0027] The IGCC power plant 10 shown schematically in FIG. 1 essentially consists of a gas turbine 12 and a gas turbine-compressor 14 connected upstream of the gas turbine 12 . Fuel, such as bituminous coal, is gasified in a gasification unit 16 for producing synthesis gas. The oxygen required for the gasification is produced in an air decomposition plant 18 in which oxygen is produced from air by fractional distillation. Air is usually taken from the environment and, by means of a gas turbine-compressor and / or a gas-turbine additional compressor, via compressor 20, fed to the air splitting plant 18 and compressed to the pressure required for fractionation.

[0028] The synthesis gas produced in the gasification unit 16 is cooled in a synthesis gas cooling unit 22 before further processing and then fed into a gas cleaning unit 24 . In the gas cleaning device 24, a filter (not shown) first retains the ash particles and then, if necessary, also removes carbon dioxide. Other ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com