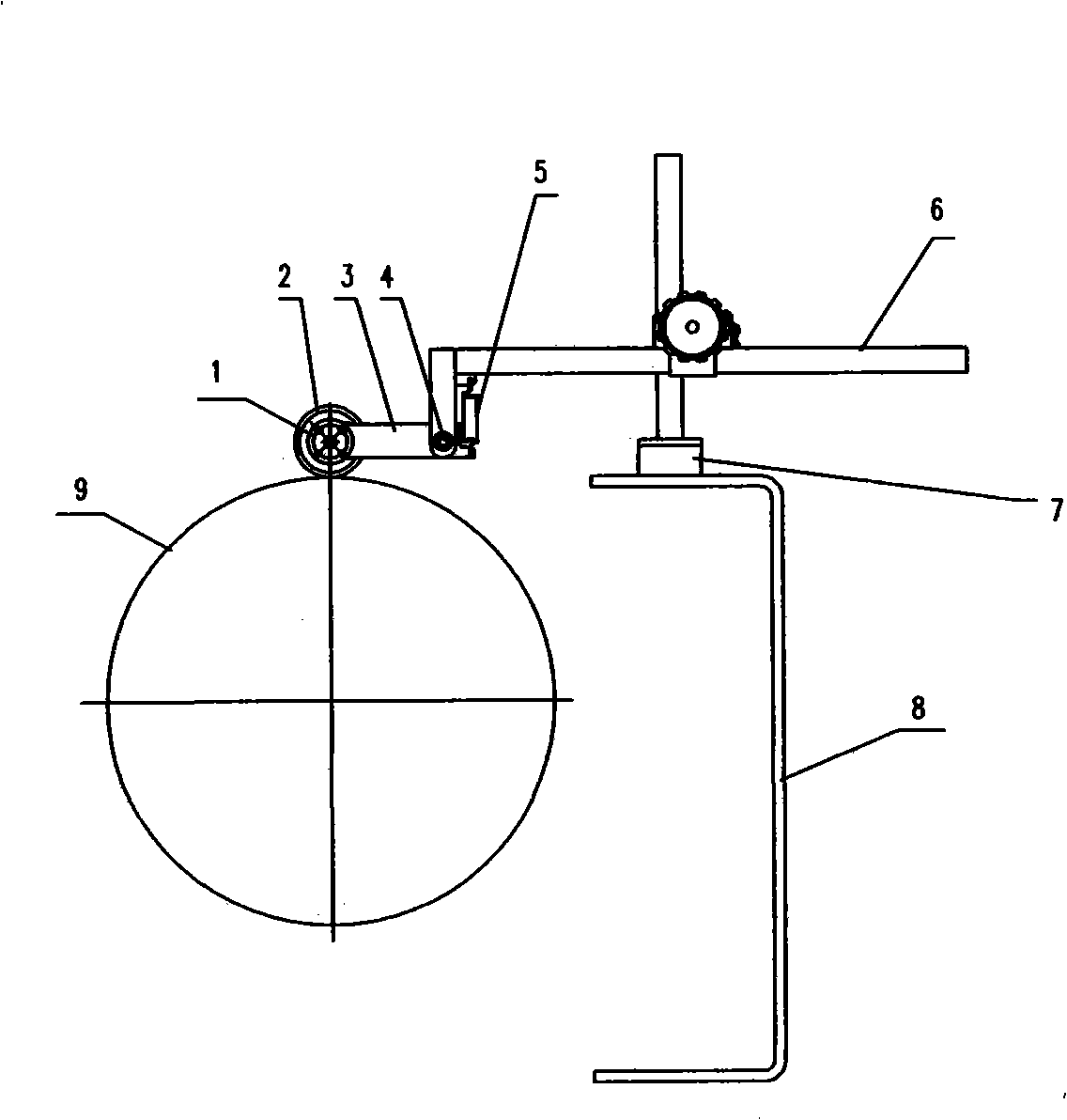

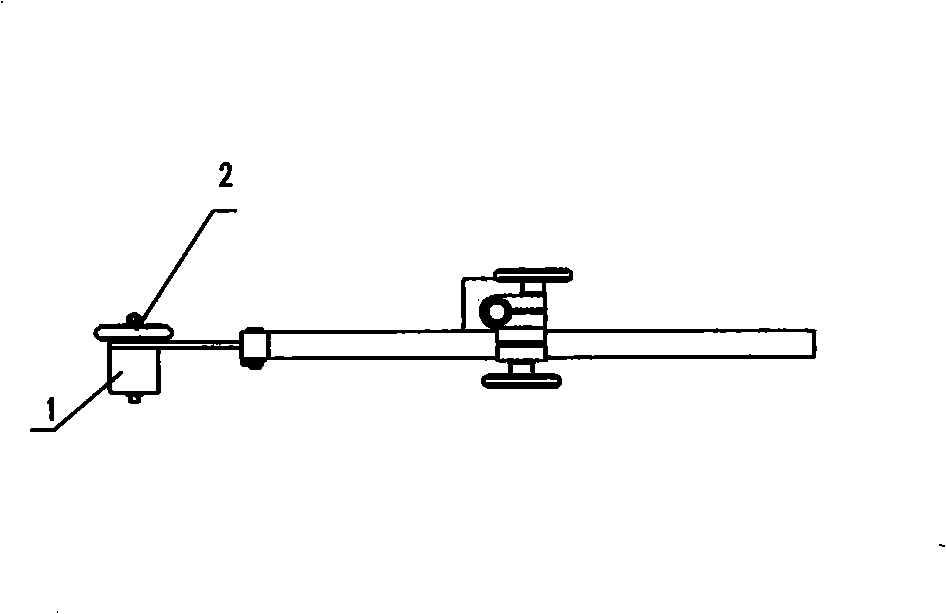

Elementary inertia meter

A basic inertia, tester technology, applied in the testing of machine/structural components, static/dynamic balance testing, instruments, etc., can solve the problem of poor data accuracy and repeatability of measurement results, inability to meet the requirements of technical indicators, and difficult assumptions. Establishment and other issues, to achieve the effects of good measurement accuracy and repeatability, light weight, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0026] Fully preheat the chassis dynamometer or the equipment to be tested according to the requirements of the equipment manual, and then proceed as follows:

[0027] 1. Drive the drum at a speed of 56km / h, and perform constant force F in the speed range of (48~16)km / h 1 =Sliding test at 1170N, the upper station records the sliding time Δt 1 (s) and the average value of the measured resistance F1(N), the measured start and end sliding speed difference ΔV 1 .

[0028] 2. Drive the drum at a speed of 56km / h, and perform constant force F in the speed range of (48~16)km / h 1 = 0N when sliding test, the upper station record the sliding time Δt 2 (s) and the average value of the measured resistance F2(N), the measured start and end sliding speed difference ΔV 2 .

[0029] 3. The upper computer obtains DIW according to the calculation formula

[0030] DIW=(F1-F2) / (ΔV 1 / Δt 1 -ΔV 2 / Δt 2 )

[0031] 4. Repeat the above measurement two more times, and find the average of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com