Titanium alloy and aluminum alloy or aluminum base compound material ultrasound precoating and soldering method

A technology of aluminum-based composite materials and brazing methods, which is applied in the direction of metal material coating technology, coating, welding equipment, etc., can solve problems such as cracks, expensive production cycles of connecting equipment, and low bonding strength of joints. Simple, low manufacturing cost, reliable connection without breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

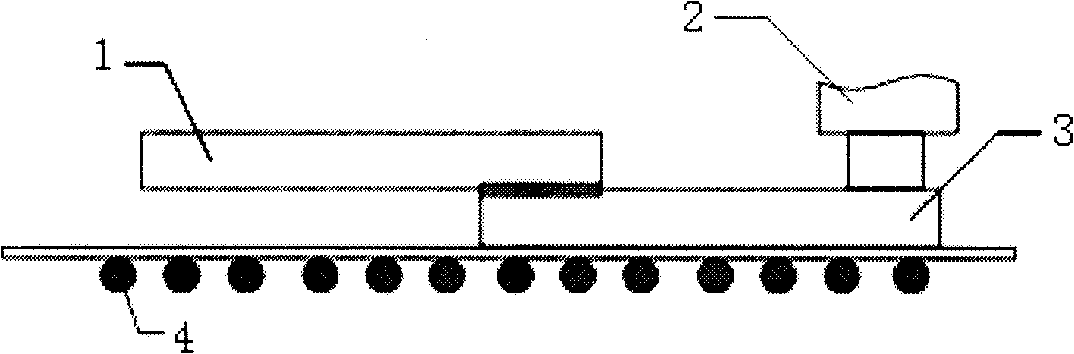

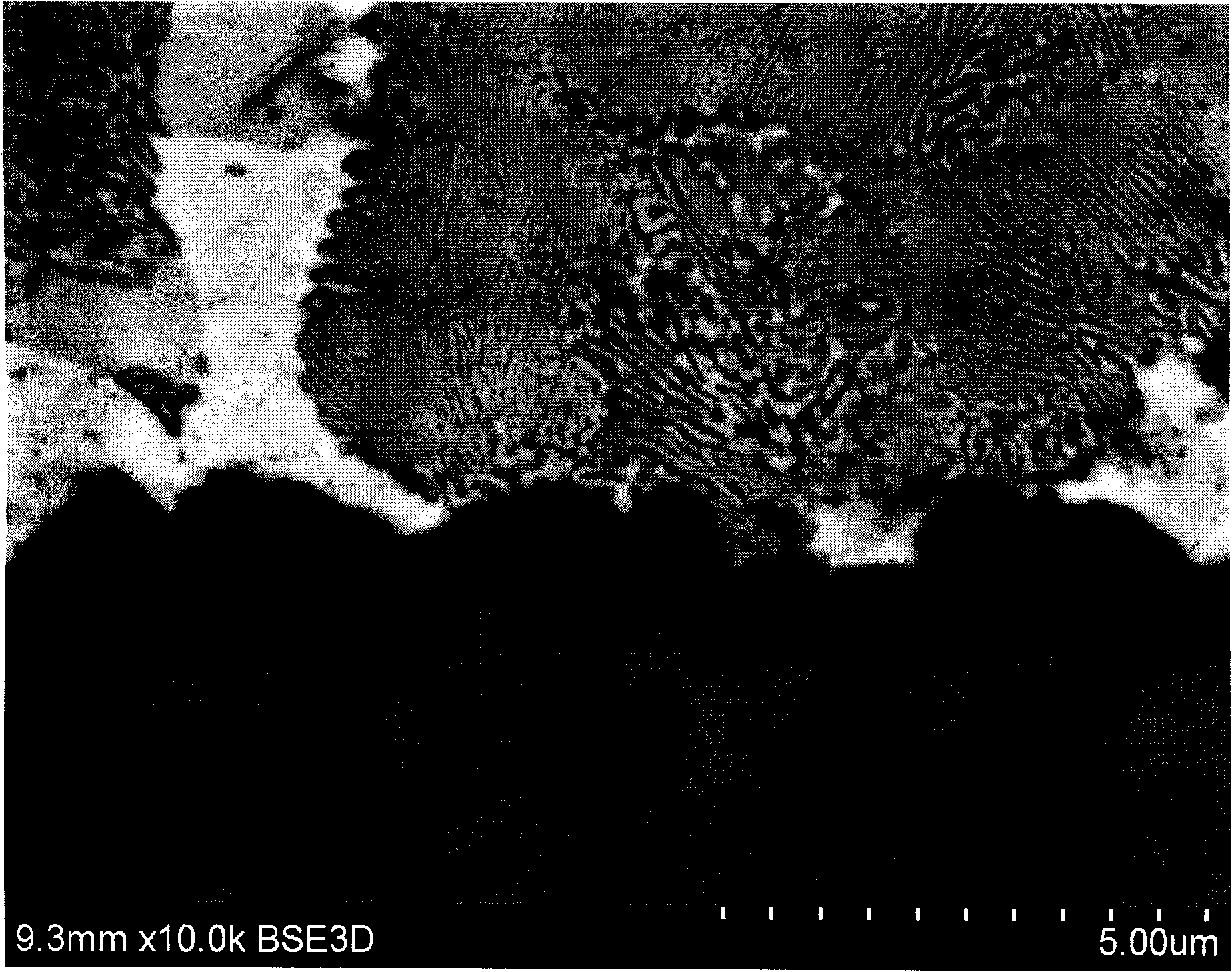

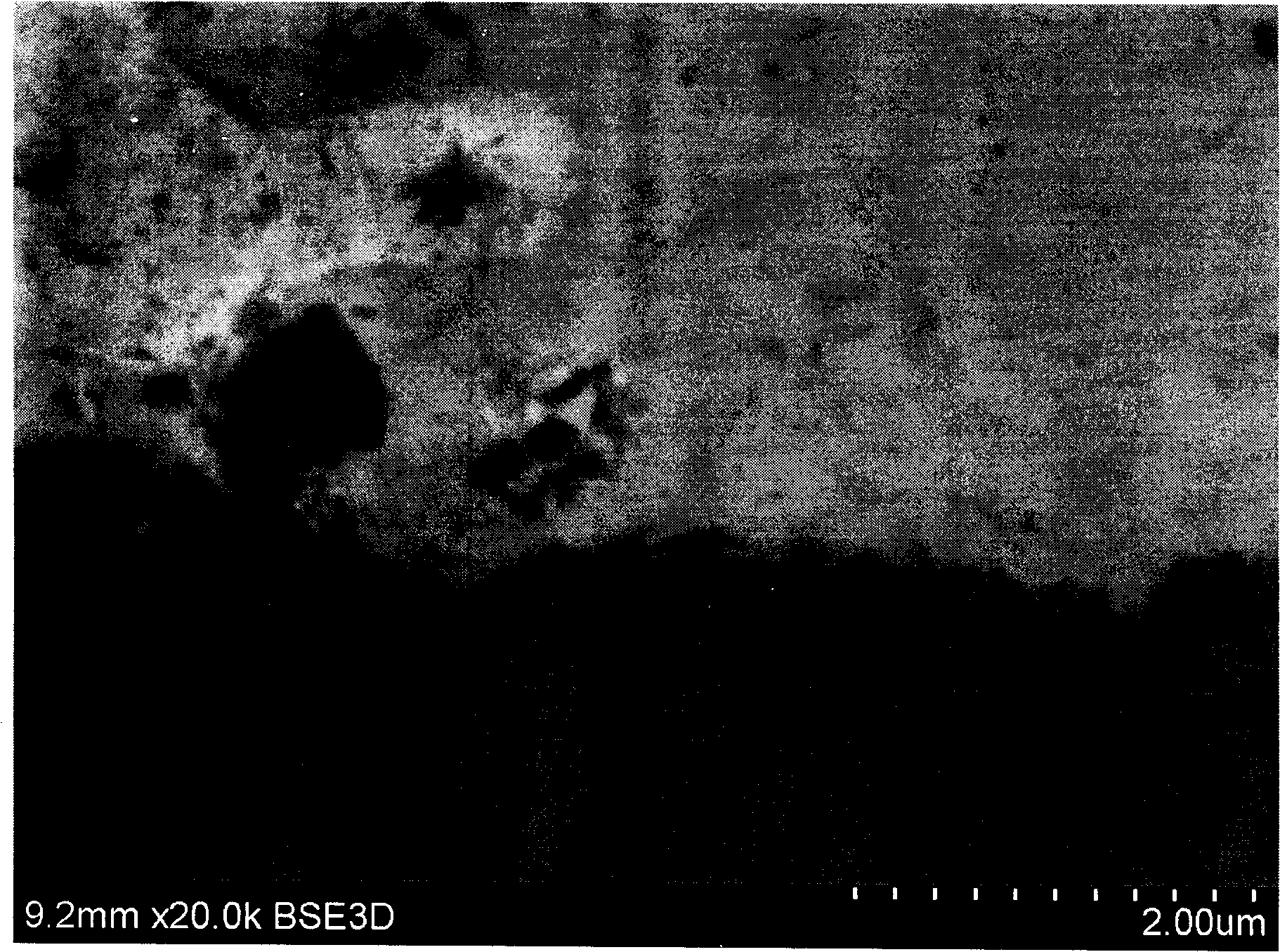

[0011] Specific Embodiment 1: In this embodiment, the ultrasonic pre-coating brazing method of titanium alloy and aluminum alloy or aluminum matrix composite material is realized through the following steps: 1. Clean the surface of titanium alloy plate and aluminum alloy or aluminum matrix composite material plate; 2. Immerse the part of the titanium alloy plate to be welded in the molten aluminum alloy at a temperature of 750-800°C, and keep the temperature constant for ultrasonic coating; 3. Grind the aluminum alloy layer coated on the surface of the titanium alloy plate, and grind it The thickness of the finished aluminum alloy layer is uniform and smooth; 4. Put the part of the ground titanium alloy plate to be welded into the solder pool. Vibration treatment under certain conditions for 1-25s; 5. Put the part to be welded of the aluminum alloy or aluminum matrix composite plate into the solder pool, at an ultrasonic frequency of 20-100kHz, an amplitude of 1-50μm, and a tem...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium alloy in the titanium alloy plate in Step 1 is TA, TB or TC series alloys. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in Step 1, the aluminum alloy in the aluminum alloy and its composite material plate is LY, LF or LD series alloy. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com