Microwave metallic halogen lamp

A metal halide lamp and microwave technology, applied in the field of light sources, can solve the problems of inability to make low color temperature lamps, poor stability of electrical parameters, and narrow application range, so as to improve light efficiency and color rendering index, stabilize photoelectric color parameters, and broaden the range of applications. The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

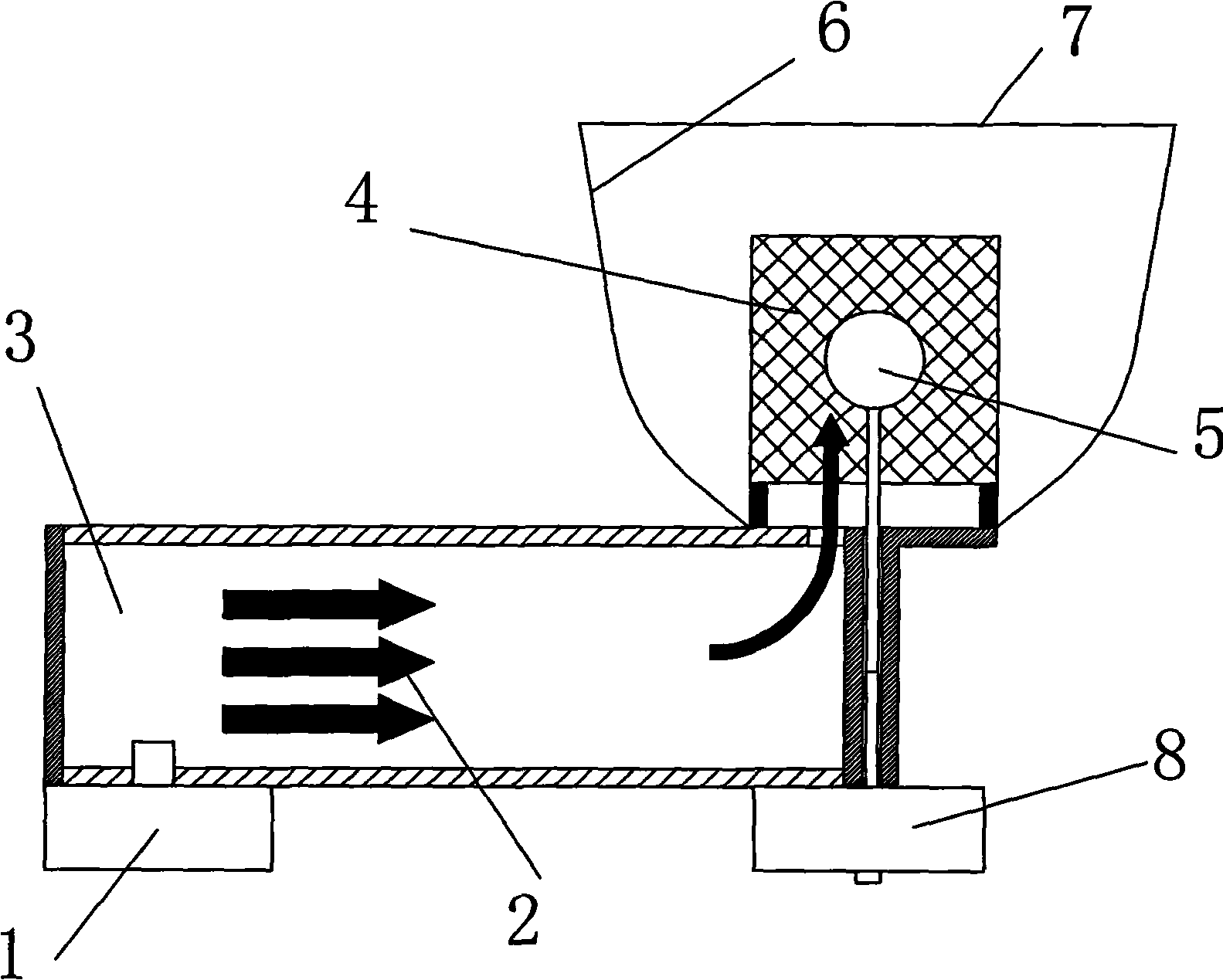

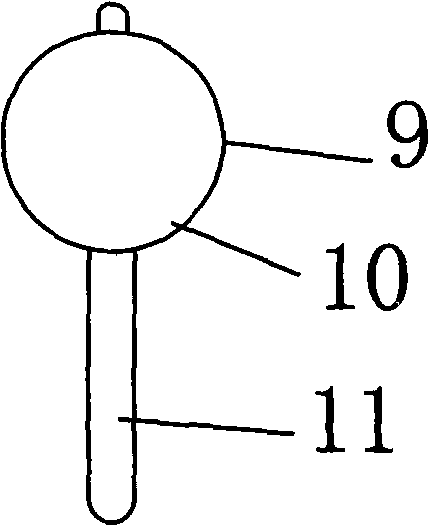

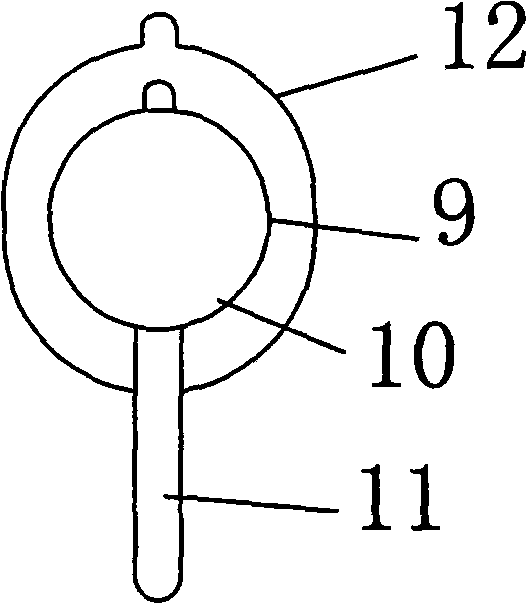

[0016] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: figure 1 As shown, the microwave metal halide lamp of the present invention includes: a magnetron 1 , a microwave 2 , a waveguide cavity 3 , a bulb 5 , a metal reflector 6 , a bulb motor 8 , a bulb 9 , and a luminescent working substance 10 . The magnetron 1 is set inside the casing, under the action of electric power, the microwave energy 2; the waveguide cavity 3 communicates with the magnetron 1, and the waveguide cavity 3 transmits the microwave to the resonant cavity 4 that can resonate the microwave energy, and the resonant cavity 4 is shielded by metal The bulb 5 is set in the resonant cavity 4, and is excited by the microwave energy in the resonant cavity to emit light. The bulb motor 8 drives the bulb 5 to rotate; the bulb 5 is filled with a luminescent working substance 10, which is mainly a metal halide In addition, a small amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com