Tridimensional distributed type material stream circulating method and ventilated synthetic energy-saving method

A distributed and material technology, applied in botany equipment and methods, ventilation systems, space heating and ventilation, etc., can solve the problem of direct discharge of hot air or hot and humid air, high investment and technical costs, and restrictions on large-scale development, etc. problems, to achieve the effect of reducing maintenance workload, reducing investment and operating costs, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

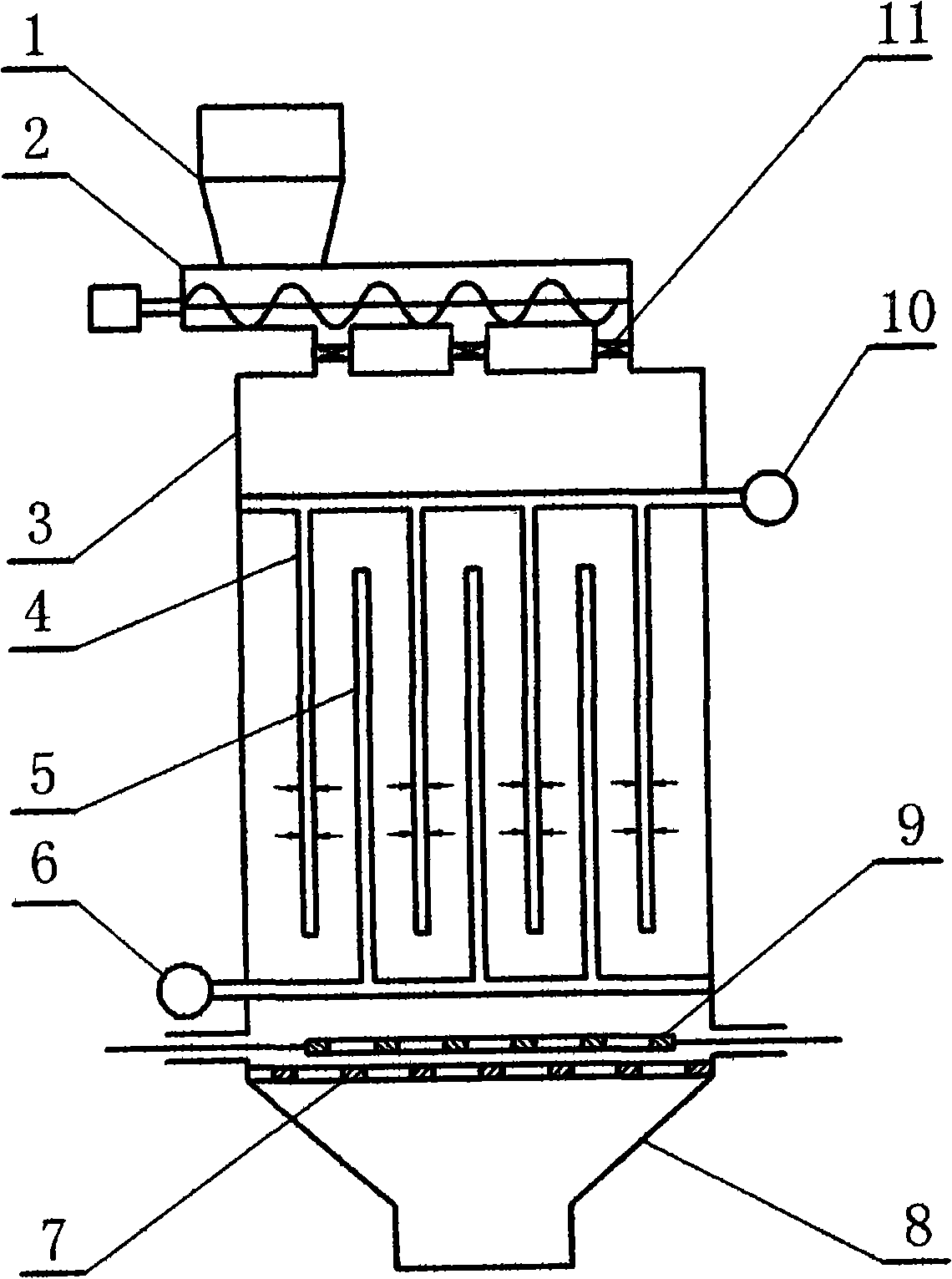

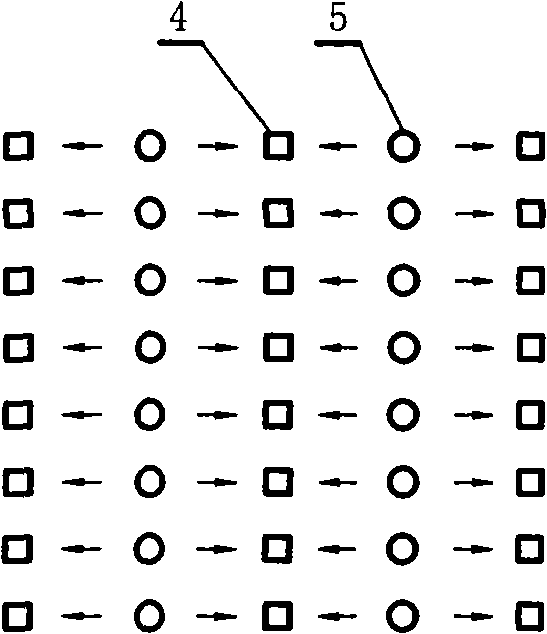

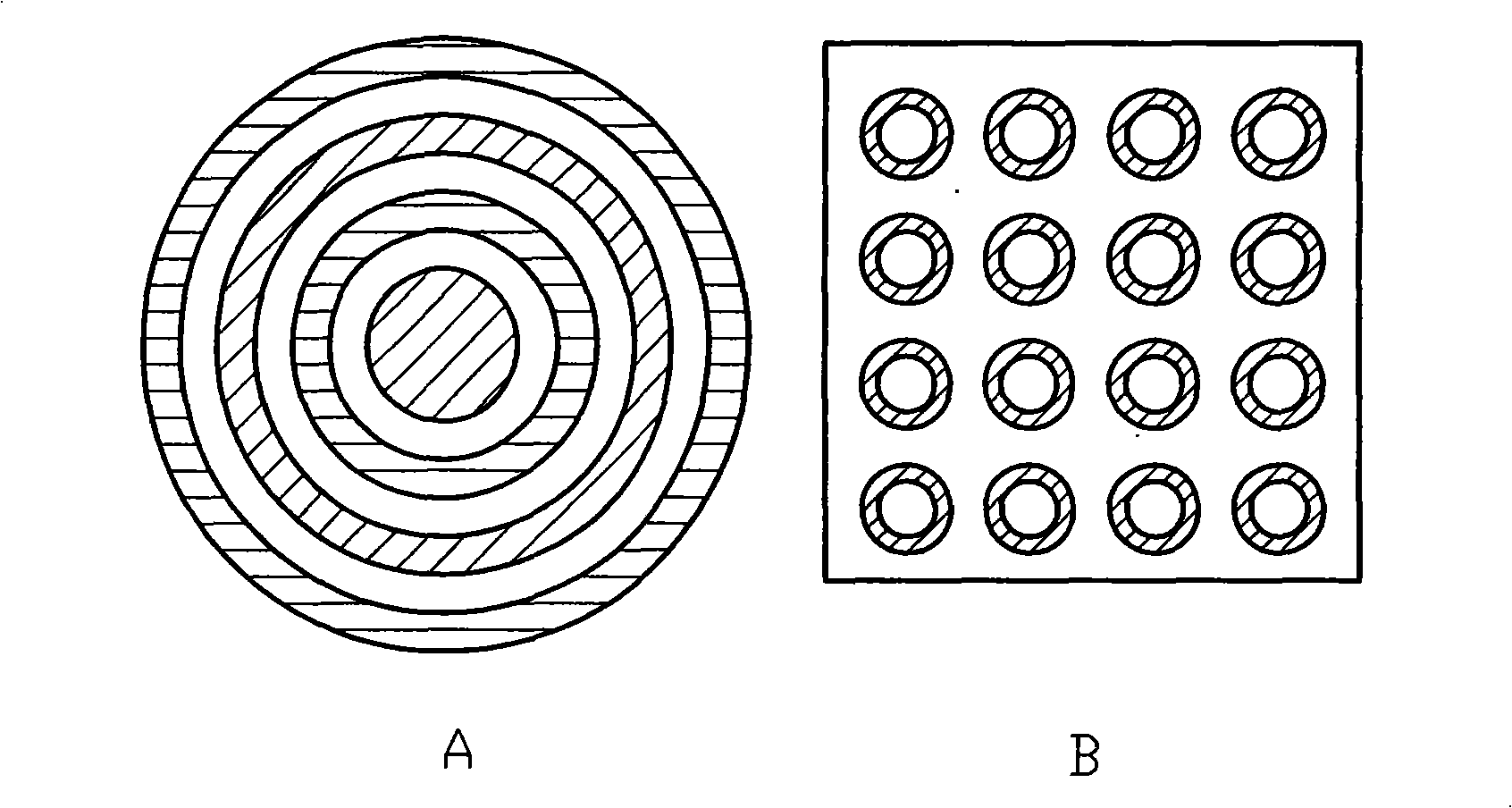

Embodiment 1

[0035] Embodiment 1: as attached figure 1 As shown, a ventilated reactor using a three-dimensional distributed ventilation method, the basic process is: after the material enters the screw distributor 2 from the storage hopper 1, it enters the reactor 3 through three distribution ports 11 and its regulating baffles. Under the action of gravity, the materials are naturally piled on the partition type material bed 7 and piled up on the ventilation pipe group in the reactor. The discharge volume or discharge speed is controlled by the partition type unloader 9 and collected by the drop hopper 8. The material that completes the reaction. A distributed air supply system is adopted, and the air is passed from the main air intake pipeline 6 to the terminal air supply pipeline group 5. Ventilation holes are distributed on the pipe wall (the pipe wall can also be grid-shaped) and the top is sealed, and the air passes through. Vent holes go into the material. Ventilation holes are als...

Embodiment 2

[0040] Embodiment 2: as attached Figure 8 As shown, similar to Example 1, a three-dimensional distributed ventilation method for biomass aerobic fermentation. The flow of materials is from top to bottom, basically the same as in Example 1. The air flow enters the material through the intake pipeline 23 and is sucked into the middle pipeline 22, and the air flow in the middle pipeline is sucked by the exhaust pipeline 21 and enters the exhaust system through the upper material layer. In this way, because the temperature of the lower layer material is higher after fermentation, the passing airflow enters the upper layer material through the intermediate pipeline, which can preheat the initial material. Due to the long natural heating cycle of organic matter fermentation, such a ventilation method is conducive to accelerating the heating of the upper material, allowing the rapid reproduction of biological bacteria, shortening the overall fermentation cycle, reducing the volume ...

Embodiment 3

[0044] Embodiment 3: Adopting is similar to attached Figure 8 The three-dimensional distributed ventilation system with the structure shown is used for pyrolysis of biomass or organic matter. The difference from fermentation is that the inside of the pyrolysis reactor must be sealed. The intake system is generally air, water vapor or oxygen, and the exhaust system is exhausted. Pyrolysis products are generally CO, H2, N2 and CH4. The basic process of operation is to start anaerobic heating to the temperature at which the pyrolysis reaction starts, gradually stop heating, start to let in air to oxidize organic matter to generate heat and heat up, and control the air intake to an appropriate temperature. Before the pyrolysis material enters the system, the air in it should be squeezed out. In order to avoid the coking and agglomeration of the pyrolysis product or control the falling speed, ribs or other protrusions can be set on the ventilation pipe network, or the ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com